Hig Efficient Wholely Assembled Box Girder Template in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

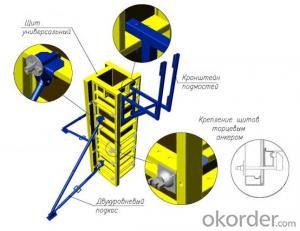

Wholely Assembled Box Girder

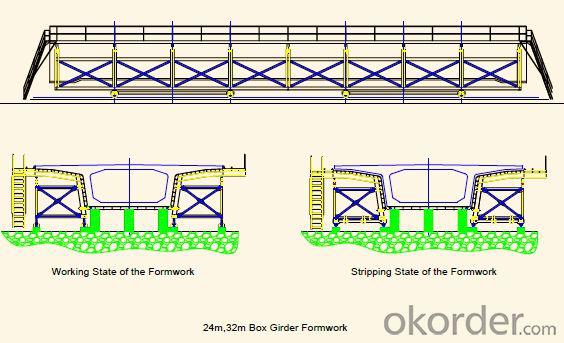

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: How to calculate the length of the beam, beam template area

- Is the template area, there are two times in each cross beam, then the results of the calculation of the sub beam cross-sectional area (a few minus a few) is the

- Q: I only see the span is greater than 4M of the beam arch height is 1/1000~3/1000, if that is 5m, 8m, 12M, 16m and even assuming 20m, the supply is only 1/1000~3/1000????

- 4.4.6 on the span of not less than 4m of the beam, the plate, the height of the template arch should be the beam, plate span 1/1000~3/1000.

- Q: When Liang Banzhong beam template calculation is the calculation of him in the board? Because in the calculation of engineering quantity of concrete beam by beam plate calculation. But when the template is, the book is not clear. In the calculation of the time quota template can have a beam plate.I use the Guizhou 04 quotaEspecially your last sentence, I haven't said anything yet,There is the Guizhou 04 fixed and did not say what sub beam frame beam separationAbove the beam plate is to explain the main beam, sub beam and plate, according to the calculation of beam and plate volumeThen you explain to me the frame beam is not the main beam? According to this explanation, why do you separate the frame beam

- Calculate the area between the axis, into the wall of the plate into the area of the plate, and then deduct more than 0.3 of the hole, that is, the area of the beam plate

- Q: What is the meaning of the steel beam overhead on the top of the beam formwork

- Because the carpenter is generally the template will be good, so that there is no reinforcement steel reinforcement

- Q: How to calculate the amount of beam template? FiveKL2: cross section size of 0.3*0.6, thickness of the 0.12 beams, 10.9 JingchangAsk: how to calculate the amount of formwork works? How to calculate the height of support?Calculation formula

- If the border, the template area = (0.6+0.6-0.12+0.3) *10.9=1.38*10.9=15.042 square

- Q: For example, a beam 200*400, length 5000Plate thickness 1005000*5000The area of the template is1, (0.2+0.3*2) *5+5*52, 0.3*2*5+5*5Which is right

- Plate side mode *2 is the circumference of the board (minus column protruding part) multiplied by the thickness of the plate 0.1M

- Q: Beam column plate template how to calculate the need to deduct what part?

- A method is relatively simple and practicalThe calculation formula of the first column is the circumference multiplied by the height of the unit is M2

- Q: How to do the foundation beam template

- The main construction method by a formwork one-time-concreting organization construction, wall, column and beam plates without construction joints, each layer of wall, column, beam plate model, a branch of Qi, while pouring concrete.

- Q: When there is a beam plate template, the beam can not be added to the template?

- Beam template and foundation beam template to separate sets of fixed!

- Q: What is the formula of beam slab formwork

- Si=F*A*B, formula, F coefficient, A, length, B width or height.Such as triangle F=0.5, A for the bottom edge of the length, B is high.

Send your message to us

Hig Efficient Wholely Assembled Box Girder Template in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords