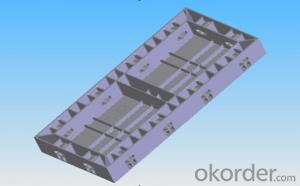

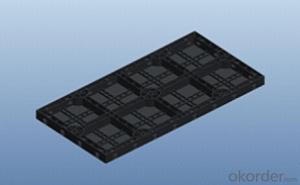

Easy Removal Plastic Formwork-Wall Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Easy Removal Plastic Formwork-Wall Formwork

Using modular formwork, it is possible to pour up to 40cm thick and 3 meters high straight walls one time. Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily. The low weight and modularity of modular formwork makes it ideal for fence walls as it is possible to move large gang-forms by hand.

Set Up Easily

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system needn’t traditional wood blocks and nails.

The panels have holes to fit tie rod, guarantee the strength of the whole system.

Easy Treatment after Pouring

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

Corner & Specification

Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily.

product name | Modular formwork |

origin | China |

color | Black |

material | PP |

weight | 11kg |

tensile strength | 40KN |

reusable | 100 times |

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- It seems to have been the introduction of hollow plastic building template production line (foreign technology), the site last year to see someone used this plastic building template, our site is now using this plastic building template material is polypropylene PP, this template Cheap, suitable for ordinary wall. There is also a material that is made of polycarbonate PC This material is suitable for viaducts, water conservancy works, pouring walls without whitewashing. The wall is very light. It is expensive point.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: Why the floor is not plastic building materials square wood and template

- Not people do not have this product is not humane is not perfect not to buy only to be used to solve the trouble of the workers with the boss's doubts

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template is the best architectural template, the advantages of a high number of turnaround, the theory is 300 times, but the actual use of 60 will have a small part of the deformation, a comprehensive calculation of 150 no problem, the second is quick, every worker day Can be assembled 20 square meters or more, three is light weight, manual transmission is very convenient, do not rely on tower crane, four is the quality assurance, the basic can meet the specifications, five is conducive to civilized construction, will not produce garbage and noise, No wood. Disadvantages of a high cost, and second, only in the standard layer to use to play advantage

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic construction template is not a good place to say, talk about the shortcomings of it, 1: the quality is too heavy, 2 intensity is not very satisfactory, 3, a little fee wooden side

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- The quality of the template is related to the quality of concrete engineering. The key lies in the accurate size, the assembly is firm, the patchwork is tight and the assembly and disassembly is convenient. Should be based on the structure of the form and characteristics of the appropriate form of template, in order to achieve good technical and economic results.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- Can be ruled length processing, can be ruled length processing, can be ruled length processing

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

Send your message to us

Easy Removal Plastic Formwork-Wall Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords