High Quality Light Steel Rail for Structure Q235, 55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Quality Light Steel Rail for Structure Q235, 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Light Steel Rail for Structure Q235, 55Q is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line, for example: railway, subway, transportation track, express, curve way, tunnel way.

Product Advantages:

OKorder's High Quality Light Steel Rail for Structure Q235, 55Q are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description of High Quality Light Steel Rail for Structure Q235, 55Q:

Specifications of High Quality Light Steel Rail for Structure Q235, 55Q

Production Standard: GB11264-89

Material: Q235, 55Q

Grade | Element(%) | ||||

C | Mn | S

| P

| Si

| |

Q235 |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

55Q | 0.50—0.60 | 0.70—1.00 | ≤0.050 | ≤0.045 | 0.15-0.35 |

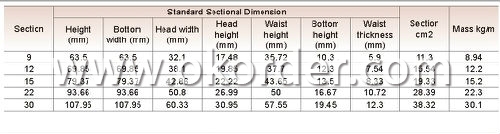

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6M, 8M, 10M, 12M or as the requriement

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Package & Delivery of Ms Light Steel Rail Q235, 55Q

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the High Quality Light Steel Rail for Structure Q235, 55Q will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Light Steel Rail Q235, 55Q

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Light Steel Rail Q235, 55Q

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

FAQ:

Q1: What is the normal tolerance of High Quality Light Steel Rail for Structure Q235, 55Q?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20fts the steel beams of High Quality Light Steel Rail for Structure Q235, 55Q?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How are steel rails aligned?

- Steel rails are aligned using a combination of precise measurements, specialized equipment, and skilled labor. The rails are first laid out along the designated track path, ensuring they are evenly spaced and properly aligned. Then, hydraulic jacks and other tools are used to adjust the rails to the correct alignment. This process involves carefully aligning the rails horizontally, vertically, and longitudinally to ensure a smooth, stable, and safe track for trains to travel on.

- Q: Are steel rails used in railway track geometry measurement systems?

- Steel rails are frequently utilized in railway track geometry measurement systems. These systems employ a range of sensors and devices to assess and evaluate track geometry, encompassing track gauge, alignment, cross level, and vertical profile. By using steel rails, these measurement systems are able to establish a robust and long-lasting base, thereby enabling the collection of precise and dependable data. Furthermore, steel rails exhibit exceptional resistance to wear, enabling them to endure heavy loads and extreme weather conditions, rendering them an optimal selection for railway tracks.

- Q: What are the different methods used for rail grinding on steel rails?

- There are several methods used for rail grinding on steel rails, including the use of grinding stones, milling machines, and rail grinders. Grinding stones are typically used for minor surface imperfections and can be manually or mechanically powered. Milling machines are used for larger scale grinding and use rotating cutters to remove material from the rail surface. Rail grinders are specialized machines that use grinding wheels to remove metal from the rail, providing a smoother and more even surface. These methods are employed to improve rail profile and reduce wear and noise levels.

- Q: What's the difference between a high-speed rail and an ordinary one?

- Not only does the train speed run faster than the train, but the infrastructure (track, signal, communication and catenary) of the train also meets the technical requirements of the speed grade.

- Q: Which companies are the main rail products used in China?

- Some iron and steel plants producing vanadium and titanium, such as Panzhihua Steel and vanadium, are wear-resistant because of the addition of vanadium

- Q: How are steel rails affected by ground settlement or shifting?

- Steel rails are affected by ground settlement or shifting in multiple ways. Firstly, if the ground settles or shifts unevenly, it can cause the steel rails to become misaligned, leading to track irregularities and potential derailments. Secondly, ground settlement or shifting can create stress and strain on the rails, which may result in warping or buckling of the tracks. This can further compromise the stability and safety of the rail system. Therefore, ground settlement or shifting poses significant challenges to the integrity and performance of steel rails.

- Q: How do steel rails handle changes in track alignment due to settlement?

- Steel rails are designed to handle changes in track alignment due to settlement by flexing and adjusting to the shifting track. The steel material allows for some degree of movement and flexibility, which helps the rails to maintain stability and continue to provide a smooth and safe passage for trains, even in the event of settlement. Additionally, regular maintenance and inspection of the tracks are conducted to identify and address any alignment issues promptly, ensuring the continuous integrity of the rail system.

- Q: Can steel rails be used for agricultural railways?

- Yes, steel rails can be used for agricultural railways. Steel rails are commonly used in various types of railways due to their durability, strength, and ability to withstand heavy loads. They can provide a stable and long-lasting track system for agricultural railways, allowing for efficient transportation of goods and equipment within agricultural areas.

- Q: What are the safety precautions for working near steel rails?

- To ensure the safety of workers when working in close proximity to steel rails, it is crucial to implement a number of safety measures. The following are key guidelines to follow: 1. Utilize proper personal protective equipment (PPE): It is essential to always wear high-visibility clothing, safety glasses, hard hats, and steel-toed boots to protect against potential hazards. 2. Acquire adequate training: Workers should undergo comprehensive training on railway safety, including understanding the risks associated with steel rails and how to work safely near them. This training should cover emergency procedures, safe distances, and proper signaling. 3. Maintain a safe distance: It is imperative to maintain a distance of at least 10 feet from operating trains and moving railcars. Respecting designated safety zones and keeping a safe distance from the tracks are crucial to avoid accidents. 4. Remain vigilant of surroundings: Always be alert to your surroundings and watch out for approaching trains. Utilize lookout points or designated crossing areas to ensure clear visibility before crossing or working near the rails. 5. Foster effective communication: Establish clear lines of communication with other workers and train operators. Utilize hand signals, radios, or other communication devices to convey important information and coordinate movements. 6. Abide by proper procedures for crossing tracks: If crossing the tracks becomes necessary, only do so at designated crossings and adhere to any specific procedures or instructions. Prior to proceeding, ensure to look both ways and listen for approaching trains. 7. Secure equipment and materials: Ensure that all equipment, tools, and materials are properly secured and stored when not in use. Loose items can pose a serious hazard if they fall onto the tracks or become entangled in moving train components. 8. Alert authorities about hazards or concerns: Immediately report any observed safety hazards or concerns to a supervisor or the appropriate authorities. This proactive approach will help prevent accidents and ensure prompt action is taken to mitigate risks. By adhering to these safety precautions, workers can significantly reduce the likelihood of accidents and injuries when working near steel rails. Always prioritize safety and follow industry best practices to establish a secure working environment.

- Q: Are there any regulations or standards governing the use of steel rails?

- Steel rails are subject to various regulations and standards to guarantee safety, reliability, and quality in railway infrastructure. The International Organization for Standardization (ISO) is a prominent regulatory body responsible for overseeing the use of steel rails. ISO 9001 establishes criteria for a quality management system, ensuring that manufacturers of steel rails follow rigorous quality control measures. Certification under ISO 9001 confirms that steel rails meet required standards, including dimensional tolerances, chemical composition, and mechanical properties. In addition to ISO standards, national railway authorities also establish specific regulations and standards. For instance, in the United States, the Federal Railroad Administration (FRA) sets regulations for the design, inspection, and maintenance of steel rails. These regulations encompass rail profile, weight, integrity, and permissible wear and defects. Railway companies and operators adhere to industry standards developed by organizations like the American Railway Engineering and Maintenance-of-Way Association (AREMA) and the European Committee for Standardization (CEN). These standards cover diverse topics such as rail profiles, hardness, fatigue resistance, and track geometry, ensuring compatibility and interoperability across railway networks. Moreover, there are regulations specifically addressing the manufacturing and testing of steel rails. These regulations focus on the manufacturing process, heat treatment, surface finish, and non-destructive testing methods like ultrasonic inspections and magnetic particle testing. Overall, the regulations and standards governing steel rail usage prioritize the safety, performance, and durability of railway infrastructure. Complying with these regulations and standards is essential for maintaining a dependable and efficient railway system, reducing the risk of accidents, and ensuring the smooth functioning of transportation networks.

Send your message to us

High Quality Light Steel Rail for Structure Q235, 55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords