Steel Heavy Rail GB2585-81 with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

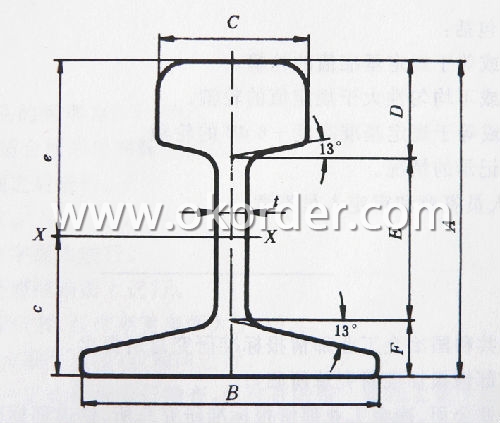

Specificaions of Steel Heavy Rail GB2585-81 with High Quality:

Production Standard: GB2585-81

Material: 50Mn, U71Mn

Grade | Element(%) | ||||

C | Mn | S | P | Si | |

50Mn | 0.48—0.56 | 0.70—1.00 | ≤0.035 | ≤0.035 | 0.17-0.37 |

U71Mn | 0.65—0.76 | 1.10—1.40 | ≤0.030 | ≤0.030 | 0.15-0.35 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Length: 10m, 12m, 12.5m or as the requriement of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usage & Applications of Steel Heavy Rail GB2585-81 with High Quality:

Heavy Steel Rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel, can also be used for tower crane and other crane track.

For example: railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Steel Heavy Rail GB2585-81 with High Quality:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Ms Heavy Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Steel Heavy Rail GB2585-81 with High Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the different types of steel rail fastening systems?

- There are several types of steel rail fastening systems used in railways, including the elastic rail clip fastening system, the SKL tension clamp fastening system, the KPO tension clamp fastening system, and the Nabla fastening system. Each system has its own unique design and function, but they all serve the purpose of securely fastening the rails to the sleepers or ties, ensuring stability and safety for train operations.

- Q: Can steel rails be easily damaged by external factors?

- Steel rails used in railway tracks are engineered to possess exceptional durability and withstand various external influences. Nevertheless, certain conditions can still lead to their damage. Extreme weather conditions represent one of the primary external influences capable of harming steel rails. In regions characterized by significant temperature fluctuations, the metal's expansion and contraction can impose stress, ultimately resulting in rail buckling or cracking. Similarly, extremely cold weather renders the steel rails brittle, thereby increasing their vulnerability to fractures or breakages. Another external factor that endangers the integrity of steel rails is excessive loads. Subjecting a rail to excessive weight or impact can cause deformation or, in severe cases, complete breakage. Overloaded trains or accidents, such as derailments or collisions, can trigger these damaging occurrences. Steel rails are also susceptible to the harmful effects of environmental factors, particularly corrosion. Moisture, chemicals, and pollutants can corrode the rail's surface, weakening its structural integrity. To mitigate this risk, regular maintenance and the application of anti-corrosion coatings are commonly employed protective measures. Furthermore, human activities, including vandalism and intentional sabotage, can inflict significant damage upon steel rails. Cutting, bending, or otherwise compromising the rails poses a severe safety hazard to both trains and passengers. Although steel rails are designed to be robust and resilient, they are not impervious. Consequently, proper maintenance, regular inspections, and timely repairs are essential to guarantee the longevity and safety of railway tracks. By addressing external factors that may potentially harm the steel rails, it becomes possible to minimize the risk of accidents and ensure the smooth operation of the railway system.

- Q: Do steel rails need to be replaced more frequently in high-traffic areas?

- In high-traffic areas, steel rails require more frequent replacement. The reason for this lies in the higher number of train movements, which causes increased wear and tear on the rails. The continuous weight and pressure exerted by the trains accelerate the wearing down process, necessitating more frequent replacements. Furthermore, heavy loads, like freight trains, are more common in high-traffic areas, further contributing to the deterioration of the rails. Hence, regular inspections and maintenance are vital in these areas to ensure the safety and efficiency of the railway system.

- Q: Can steel rails be used in curved track sections?

- Curved track sections can indeed utilize steel rails. In fact, steel rails are widely employed in railway tracks, even in areas with curves. Steel rails possess numerous advantages that render them appropriate for curved tracks. To begin with, steel is a robust and enduring material, capable of enduring heavy loads and high speeds. This quality renders steel rails highly suitable for curved sections, where tracks are subjected to heightened stress and forces. Furthermore, steel rails can be produced in various lengths and shapes, thereby allowing for flexibility in the design and construction of curved tracks that align with the specific requirements of the rail network. Additionally, steel rails can be effortlessly welded together, facilitating seamless and smooth transitions between straight and curved track sections. In conclusion, the application of steel rails in curved track sections guarantees stability, safety, and efficient transportation throughout the railway system.

- Q: What is the method of rail butt welding?

- So, if not because of special circumstances such as fracture of the steel rail or rail reaches the service life limit requires replacement or rail damage seriously to reach or exceed the standard replacement, in addition does not recommend the use of thermit welding in rail seamless line.

- Q: What are the potential risks of using steel rails?

- Some potential risks of using steel rails include corrosion, which can weaken the rails over time and increase the likelihood of accidents. Another risk is the potential for breakage or fatigue cracks due to heavy loads or extreme weather conditions. Additionally, steel rails can become slippery when wet, posing a risk for trains to lose traction and potentially derail. Regular maintenance and inspections are crucial to mitigate these risks and ensure safe rail operations.

- Q: What are the design considerations for steel rails in high-speed rail systems?

- To ensure the durability and strength required for high-speed trains, there are several crucial considerations when designing steel rails for high-speed rail systems. These considerations include the selection of the steel material, the shape and dimensions of the rail profile, the geometric alignment of the rails, the design of the track structure, the need for regular maintenance and inspection, the control of noise and vibration, accounting for thermal expansion, and ensuring compatibility with rolling stock. Firstly, the choice of steel material is essential to meet the demands of high-speed trains. Different grades of steel with properties like high tensile strength and resistance to wear and fatigue are critical. Secondly, the shape and dimensions of the rail profile play a significant role in providing stability, smoothness, and minimizing the impact on the train's wheels. Designing the profile carefully helps reduce rolling resistance and ensures proper wheel-to-rail contact. Thirdly, the geometric alignment of the rails, including curvature and elevation changes, must be meticulously crafted to allow safe and comfortable travel at high speeds. Factors like train stability, lateral forces, and passenger comfort must be taken into account. Fourthly, the design of the track structure, including rail fastening systems, sleepers or ties, and ballast, is crucial to provide stability and support for the rails. It should withstand dynamic loads imposed by high-speed trains while maintaining proper alignment and preventing track deformation. Fifthly, high-speed rail systems require regular maintenance and inspection for safety and efficiency. The design should facilitate easy access for inspection and maintenance activities, and advanced monitoring systems should be used to detect any potential defects or issues. Sixthly, measures to minimize noise and vibration levels must be considered in the design. This can include using noise barriers, resilient rail fastenings, and track damping solutions to mitigate the impact on nearby residents and infrastructure. Seventhly, designing for thermal expansion is crucial as steel rails expand and contract with temperature changes. This ensures that the rails maintain proper alignment and prevent buckling or other deformations. Lastly, the design of the steel rails must be compatible with the rolling stock, including train wheels and suspension systems. This ensures smooth and stable train operations, reducing wear and tear on both the rails and rolling stock. In conclusion, engineers must carefully consider material selection, rail profile, geometric alignment, track structure, maintenance and inspection, noise and vibration control, thermal expansion, and compatibility with rolling stock when designing steel rails for high-speed rail systems. By paying attention to these factors, engineers can create a safe, efficient, and reliable rail system for high-speed trains.

- Q: How are steel rails protected from damage caused by wildlife?

- Steel rails are typically protected from damage caused by wildlife through the use of various measures such as fencing, wildlife deterrents, and regular inspections. Fencing helps to prevent animals from accessing the tracks, while wildlife deterrents like noise devices or visual deterrents are used to scare away animals. Additionally, regular inspections allow for the identification and removal of any potential hazards or obstacles that could cause damage to the steel rails.

- Q: Can steel rails be customized for specific rail applications?

- Customization of steel rails for specific rail applications is possible. Manufacturers produce steel rails in various sizes and specifications to meet the specific demands of different rail applications. These applications encompass heavy-haul freight, high-speed passenger, tramways, and light rail, each with distinct requirements pertaining to load capacity, durability, and track geometry. To cater to these specific needs, customization options for steel rails are available. Firstly, rail size and weight can be adjusted to accommodate varying loads and traffic volumes. For instance, heavy-haul freight rails are typically larger and heavier to withstand increased loads and stresses. Furthermore, the composition and quality of the steel can be modified to enhance durability and longevity. Rail manufacturers have the capability to utilize different grades of steel and apply specific heat treatments, thereby improving strength and resistance to wear and fatigue. Moreover, rail geometry can be tailored for specific applications. This involves adjusting the rail profile, including head width, height, and gauge, to ensure proper alignment, stability, and compatibility with rolling stock. In summary, steel rails can be customized to meet the specific requirements of different rail applications, encompassing size, strength, durability, and geometry. This enables optimal performance and safety across diverse rail systems worldwide.

- Q: How are steel rails classified based on their weight?

- Steel rails are classified based on their weight using a standardized system that categorizes them into different classes such as light, medium, and heavy rails.

Send your message to us

Steel Heavy Rail GB2585-81 with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords