High Quality Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

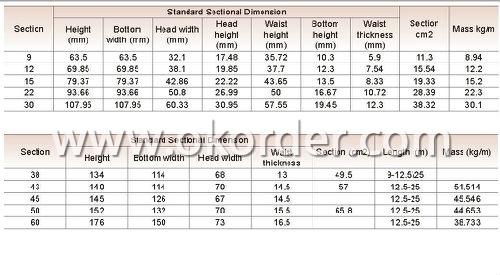

Specifications of High Quality Steel Rail

Product Name: High Quality Steel Rail

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

55Q

|

0.50—0.60 |

0.70—1.00 |

≤0.050 |

≤0.045

|

0.15-0.35

|

Applications of High Quality Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of High Quality Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Invoicing on theoretical weight or actual weight as customer request

8. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of High Quality Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: What is the weight per meter of steel rails?

- The weight per meter of steel rails varies depending on the specific type and size of the rail, but typically ranges between 40 and 60 kilograms per meter.

- Q: How do steel rails affect train ride comfort?

- The comfort of a train ride is greatly influenced by steel rails. To begin with, these rails ensure a smooth and stable track surface for the train to travel on. By maintaining a consistent and even surface, the rails prevent sudden jolts or bumps, resulting in a more comfortable ride for passengers. Furthermore, steel rails are designed to minimize the vibrations and noise produced by the train. They effectively absorb the impact and vibrations caused by the wheels, reducing the transmission of these disturbances to the train and its passengers. This dampening effect helps to alleviate the discomfort and fatigue that passengers may experience during their journey. In addition, steel rails are engineered to maintain their shape and alignment even over long distances. This is vital because any irregularities or misalignment in the track can lead to a bumpy and uncomfortable ride. Steel rails are specifically designed to withstand wear and tear, ensuring a consistently comfortable ride for passengers. In conclusion, steel rails play a significant role in enhancing the comfort of a train ride. They provide a stable, smooth, and low-vibration track surface, minimizing jolts, vibrations, and noise. This ultimately enhances the overall experience for passengers, making their journey more pleasant and enjoyable.

- Q: How do steel rails handle changes in track gauge?

- Steel rails are designed to handle changes in track gauge by being flexible and durable. They provide stability and support to the train, allowing it to smoothly transition from one gauge to another without causing any disruptions or derailments. This is achieved through careful engineering and design, ensuring that the rails can accommodate variations in gauge while maintaining their structural integrity.

- Q: Can steel rails be used in freight transportation?

- Yes, steel rails are commonly used in freight transportation. They provide a durable and reliable track infrastructure that can support heavy loads and facilitate the movement of freight trains efficiently and safely.

- Q: Can steel rails be reused if a track is decommissioned?

- Yes, steel rails can be reused if a track is decommissioned. They can be salvaged, inspected for any damage or wear, and then refurbished for use in other railway tracks or repurposed for other construction projects. Recycling and reusing steel rails helps reduce waste and conserves resources.

- Q: Can steel rails be used in underground subway systems?

- Yes, steel rails can indeed be used in underground subway systems. Steel rails are commonly used in subway systems worldwide due to their durability, strength, and ability to withstand heavy loads and frequent use. They provide stability, smoothness, and safety for trains traveling underground, making them a reliable choice for subway infrastructure.

- Q: How do steel rails handle curves in railway tracks?

- The purpose of steel rails is to efficiently navigate curves in railway tracks. They possess various characteristics that enable them to achieve this goal. To begin with, steel rails have a specific shape called the "rail head." This shape is slightly curved, allowing the train wheels to smoothly roll along the track when encountering a curve. The curvature of the rail head ensures that the train remains stable and does not derail while going around bends. Furthermore, steel rails are designed with a high degree of flexibility. They are capable of absorbing the lateral forces that arise when a train traverses a curve. The rails' flexibility permits them to bend slightly under the weight of the passing train, reducing stress on the rail and guaranteeing a safe and comfortable journey. In addition, steel rails are often installed using a technique known as "canting" or "super elevation." This technique involves tilting the rails slightly towards the center of the curve. By doing so, the train is compelled towards the middle of the track, countering the centrifugal force that pushes the train outward during a curve. This technique enhances the stability and safety of the train when navigating curves. In some instances, the rails may also incorporate additional features like flanges or guardrails. These elements assist in guiding the train wheels along the track and preventing them from slipping off the rails, particularly during sharp curves. Overall, steel rails are engineered to effectively handle curves in railway tracks by providing a smooth, flexible, and stable surface for the train wheels to roll upon. Through their distinctive shape, flexibility, and supplementary features, they ensure the safe and efficient operation of trains when encountering curves.

- Q: Can steel rails be customized for specific track requirements?

- Yes, steel rails can be customized for specific track requirements. Steel rails are manufactured in various sizes and specifications to meet the specific needs of different types of tracks. For instance, the length, weight, and cross-sectional shape of the rails can be tailored to meet the specific requirements of a particular track. Additionally, the steel used in the rails can be customized to have specific properties such as strength, durability, and resistance to wear and tear. This customization allows for the construction of tracks that can handle heavy loads, high speeds, or challenging terrain. Furthermore, steel rails can be designed to accommodate different types of rail fastening systems, allowing for flexibility in track construction and maintenance. Overall, the ability to customize steel rails makes them a versatile and adaptable choice for meeting the specific requirements of different tracks.

- Q: Are steel rails used in monorail systems?

- Yes, steel rails are commonly used in monorail systems.

- Q: What is the process of replacing steel rails?

- To ensure the safe and efficient replacement of old steel rails with new ones, a series of steps are undertaken. Here is a general outline of the process: 1. Assessment and planning: Before replacing the steel rails, a comprehensive evaluation of the existing rails is conducted to determine their condition and the need for replacement. This evaluation includes inspections for wear and tear, damage, and any indications of fatigue or deformation. Based on this assessment, a detailed plan is devised, considering factors such as the length of track to be replaced, the type of rail to be used, and any necessary maintenance or repairs. 2. Material procurement: Once the plan is finalized, the required materials for replacement are obtained. This includes acquiring the new steel rails, fasteners, clips, bolts, and any other components necessary for installation. 3. Preparation: Before replacing the rails, the track area undergoes preparation. This involves clearing the area of any obstacles, removing the old rails, and examining the underlying track structure for any defects or weaknesses that require attention. 4. Rail removal: The old rails are carefully extracted from the track using specialized equipment like cranes, rail pullers, or rail saws. Great care is taken to prevent any damage to the surrounding infrastructure or adjacent rails. 5. Installation of new rails: The new rails are then installed in the designated track area. This process entails aligning the rails accurately, securing them with fasteners and bolts, and ensuring proper connection and joining to maintain the track's integrity. 6. Testing and inspection: Once the new rails are installed, rigorous testing and inspection are conducted to ensure their functionality and safety. This includes verifying correct alignment, performing stress tests, checking for any defects or irregularities, and ensuring secure fastening of the rails. 7. Finishing touches: After successful testing and inspection, any necessary adjustments or finishing touches are made to complete the replacement process. This may involve additional maintenance work on the surrounding track area, such as replacing ballast or leveling the track. In conclusion, the replacement of steel rails demands meticulous planning, skilled labor, and adherence to safety protocols. It is imperative to comply with industry standards and regulations to guarantee the durability and dependability of the railway infrastructure.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords