Ms Heavy Steel Rail 50Mn, U71Mn

- Loading Port:

- Qingdao Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

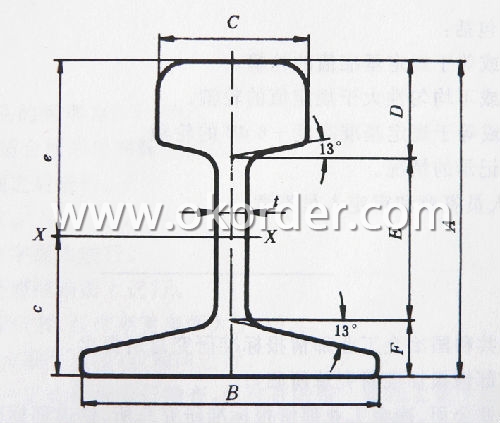

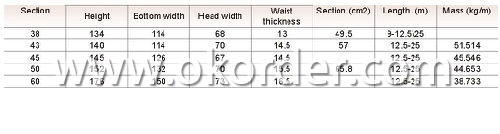

Specificaions of Ms Heavy Steel Rail 50Mn, U71Mn

Production Standard: GB2585-81

Material: 50Mn, U71Mn

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

50Mn |

0.48—0.56 |

0.70—1.00 |

≤0.035 |

≤0.035

|

0.17-0.37 |

U71Mn | 0.65—0.76 | 1.10—1.40 | ≤0.030 | ≤0.030 | 0.15-0.35 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Length: 10m, 12m, 12.5m or as the requriement of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usage & Applications of Ms Heavy Steel Rail 50Mn, U71Mn

Heavy Steel Rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel, can also be used for tower crane and other crane track.

For example: railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Ms Heavy Steel Rai 50Mn, U71Mn

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Ms Heavy Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Heavy Steel Rail 50Mn, U71Mn

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Heavy Steel Rail 50Mn, U71Mn

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: Can steel rails be used for airport tram systems?

- Yes, steel rails can be used for airport tram systems. Steel rails are commonly used in tram systems due to their durability, strength, and ability to handle heavy loads. Additionally, steel rails provide a smooth and stable ride, making them suitable for airport tram systems that require efficient transportation of passengers and luggage.

- Q: Can steel rails be used in areas with high electromagnetic interference?

- Indeed, areas with high electromagnetic interference can accommodate the utilization of steel rails. Steel, being a remarkably conductive substance, efficiently dissipates electromagnetic interference (EMI) and furnishes a dependable electrical grounding. Furthermore, appropriate grounding systems are frequently incorporated into steel rail tracks to minimize the influence of EMI. Nevertheless, it is crucial to acknowledge that certain measures must be adopted to guarantee minimal interference. These measures include properly shielding electrical equipment and cables, employing surge protection devices, and adhering to best practices for EMI mitigation.

- Q: What is the typical hardness of steel rails?

- The typical hardness of steel rails ranges from 200 to 400 Brinell hardness scale (HB).

- Q: What are the advantages of continuous welded steel rails?

- Continuous welded steel rails offer several advantages over traditional jointed rails. Firstly, they provide a smoother and more comfortable ride for trains, as there are no gaps or bumps caused by rail joints. This leads to increased safety and reduced wear and tear on both the train and the tracks. Secondly, continuous welded steel rails have higher strength and durability compared to jointed rails. They are less prone to cracking, breaking, or becoming misaligned, resulting in reduced maintenance costs and longer lifespan of the tracks. Additionally, these rails improve the efficiency and speed of trains. The absence of rail joints eliminates the need for slow-downs or speed restrictions during transitions, allowing trains to maintain higher speeds and operate more efficiently. Moreover, continuous welded steel rails contribute to noise reduction as they minimize the noise generated by the wheels passing over rail joints, resulting in a quieter environment for both passengers and nearby communities. In conclusion, continuous welded steel rails enhance safety, provide a smoother ride, increase durability, improve efficiency, and reduce noise, making them a preferred choice for modern railway systems.

- Q: Can steel rails be used for magnetic levitation (maglev) trains?

- Maglev trains cannot utilize steel rails as they lack the necessary magnetic properties. Steel is a ferromagnetic material, meaning it can be magnetized but loses its magnetism once the external magnetic field is removed. Strong and stable magnetic fields are essential for maglev trains to achieve levitation and propulsion, which cannot be achieved with steel rails. To enable maglev technology, alternative materials or systems must be used. One common approach involves the use of superconducting magnets, which generate intense magnetic fields without the need for a continuous power supply. These magnets are mounted on the train and interact with the guideway's electromagnets to achieve levitation and propulsion. In conclusion, steel rails are incompatible with maglev train systems due to their insufficient magnetic properties. Specialized technologies, such as superconducting magnets, are necessary to enable the magnetic levitation and propulsion relied upon by maglev trains.

- Q: How are steel rails affected by high-speed train aerodynamics?

- Steel rails are affected by high-speed train aerodynamics in several ways. The air resistance generated by the train's movement at high speeds creates a phenomenon known as "aerodynamic uplift," which can cause the steel rails to experience increased wear and tear. Additionally, the intense air pressure changes caused by the train passing through tunnels or bridges can exert forces on the rails, potentially leading to deformation or damage. To mitigate these effects, engineers design railway tracks with specific profiles and implement measures such as track maintenance and aerodynamic fairings to ensure the safe and efficient operation of high-speed trains.

- Q: What are the safety measures for steel rail construction near water bodies?

- Some safety measures for steel rail construction near water bodies include implementing proper drainage systems to prevent water accumulation, reinforcing the foundations to withstand water pressure, using corrosion-resistant materials to prevent rusting, conducting regular inspections for any signs of erosion or weakening, and ensuring proper signage and barriers to prevent accidents or unauthorized access. Additionally, trained personnel should be equipped with appropriate safety gear and follow proper safety protocols to minimize risks during construction near water bodies.

- Q: How are steel rails protected against abrasive materials?

- Steel rails are protected against abrasive materials through a combination of design and maintenance practices. To begin with, the steel rails themselves are made from a high-quality alloy that is specifically designed to withstand wear and tear caused by abrasive materials. The alloy used in rail manufacturing is typically hardened to enhance its durability and resistance to abrasion. In addition to using a suitable alloy, rail surfaces are also treated with various protective coatings. One common method is the application of a layer of zinc, known as galvanization. This zinc coating acts as a sacrificial layer, corroding before the steel is affected by abrasive materials. Another method involves the use of special paint or polymer coatings that create a barrier between the rail surface and abrasive substances, preventing direct contact and reducing wear. Furthermore, regular maintenance practices play a crucial role in protecting steel rails against abrasive materials. Rail operators employ various techniques to keep the rails clean and free from debris that could cause abrasion. This includes regularly inspecting and cleaning the rails, as well as removing any buildup of materials that may have accumulated. Additionally, specialized maintenance vehicles equipped with brushes or high-pressure water jets are used to remove dirt, sand, or other abrasive particles that may have adhered to the rail surface. Overall, a combination of proper material selection, protective coatings, and diligent maintenance practices helps to ensure that steel rails are effectively protected against abrasive materials. By implementing these measures, rail operators can extend the lifespan of the rails and maintain their safety and performance over time.

- Q: What are the advantages of steel rails?

- There are several advantages of steel rails in comparison to other materials used for railway tracks. Firstly, steel is a highly durable material that can withstand heavy loads and constant wear and tear. This makes steel rails ideal for supporting the weight of trains and maintaining structural integrity over long periods of time. Secondly, steel rails offer excellent resistance to weather conditions and corrosion. This is particularly important in areas with high moisture levels or extreme temperatures. Steel rails are able to withstand these environmental factors without significant degradation, ensuring the safety and reliability of the railway tracks. Another advantage of steel rails is their versatility. Steel can be easily shaped and molded into various designs and sizes, allowing for customization based on the specific requirements of the railway system. This flexibility makes it possible to construct tracks with different curves, elevations, and inclinations, providing a smooth and efficient ride for trains. Additionally, steel rails have low maintenance requirements. They require minimal repairs and replacements over time, resulting in lower costs for maintenance and operation. Moreover, steel is a recyclable material, which means that old or damaged rails can be melted down and reused, making it an environmentally friendly choice. Furthermore, steel rails have excellent strength-to-weight ratio, meaning they can support heavy loads while being relatively lightweight. This advantage translates into reduced energy consumption and improved fuel efficiency for trains, resulting in lower operating costs and reduced carbon emissions. Overall, the advantages of steel rails include durability, resistance to weather and corrosion, versatility, low maintenance requirements, recyclability, and improved efficiency. These factors make steel rails the preferred choice for railway infrastructure, ensuring safe and reliable transportation for passengers and goods.

- Q: How are steel rails inspected for defects and damages?

- Steel rails are inspected for defects and damages through various methods including visual inspections, ultrasonic testing, magnetic particle inspection, and automated inspection systems. These inspections help identify cracks, wear, corrosion, and other issues that may compromise the integrity of the rails.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Heavy Steel Rail 50Mn, U71Mn

- Loading Port:

- Qingdao Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords