Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

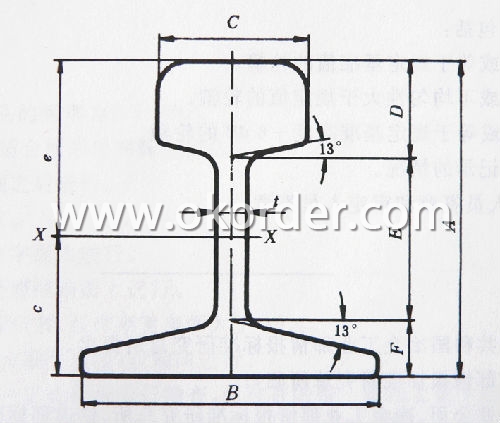

Specifications of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260, etc.

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays

Images:

- Q: Can steel rails be electrified?

- Yes, steel rails can be electrified. Electrification of steel rails is a common practice in many modern railway systems. By running an electric current through the steel rails, trains can be powered without the need for traditional diesel engines. This method of electrification offers several advantages, including greater energy efficiency, reduced emissions, and increased speed. Electric trains that run on steel rails are also quieter and have lower maintenance requirements compared to their diesel counterparts. Electrification of steel rails is achieved through various methods, such as overhead wires, third rails, or a combination of both. The electric current is then collected by the train through a pantograph or a shoe that makes contact with the electrified rail. Overall, electrification of steel rails is a proven and widely adopted technique that enhances the performance and sustainability of railway systems.

- Q: Can steel rails be used in railway systems with frequent train stops?

- Yes, steel rails can be used in railway systems with frequent train stops. Steel rails are durable and have high load-bearing capacity, making them suitable for heavy train traffic, including systems with frequent stops. Additionally, steel rails are resistant to wear and tear, which ensures their longevity even in demanding conditions.

- Q: Are steel rails prone to wear and tear?

- Yes, steel rails are prone to wear and tear. Over time, the constant pressure and friction from heavy train traffic can cause the steel rails to deteriorate. Factors such as weather conditions, the weight of the trains, and the speed at which they travel can all contribute to the wearing down of the rails. As a result, the surface of the rails can become rough and uneven, leading to increased vibrations, noise, and potential safety hazards. To mitigate this wear and tear, regular maintenance and inspections are necessary to identify and repair any damaged or worn sections of the rails. Additionally, advancements in rail technology, such as the use of hardened steel or composite materials, are being explored to increase the durability and lifespan of steel rails.

- Q: What are the safety measures for workers during steel rail maintenance?

- Safety measures for workers during steel rail maintenance are crucial to prevent accidents and ensure the well-being of the workers. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Workers should be provided with appropriate PPE, including hard hats, safety glasses, ear protection, high-visibility clothing, gloves, and steel-toed boots. This equipment helps protect them from potential hazards on the worksite. 2. Hazard Identification and Control: Regular inspection of the work area should be conducted to identify potential hazards such as uneven surfaces, loose materials, or tripping hazards. Adequate controls, such as barricades, warning signs, or safety cones, should be implemented to prevent accidents. 3. Training and Supervision: Workers should receive proper training on safety procedures and protocols related to steel rail maintenance. This training should cover topics such as proper tool usage, emergency response, and safe work practices. Additionally, supervisors should be present to provide guidance and monitor adherence to safety guidelines. 4. Lockout/Tagout Procedures: Steel rail maintenance often involves working with heavy machinery and equipment. Workers must follow strict lockout/tagout procedures to ensure that machines are safely shut down, de-energized, and locked out before any maintenance work is performed. This prevents accidental startup or release of stored energy. 5. Fall Protection: Working at heights is common during steel rail maintenance. Workers should use appropriate fall protection systems, such as harnesses and safety nets, when working on elevated surfaces or near edges. Guardrails or barriers should also be installed to prevent falls. 6. Communication and Signaling: Proper communication among workers is essential to ensure everyone is aware of ongoing activities and potential hazards. Signaling systems, such as hand signals or radios, should be used to convey important messages clearly and efficiently. 7. Ergonomics: Steel rail maintenance often involves repetitive tasks or heavy lifting. Employers should provide ergonomic training to workers and implement measures to minimize strain and injury, such as using lifting aids, providing proper lifting techniques, and scheduling regular breaks. 8. Emergency Preparedness: Workers should be trained in emergency procedures, including evacuation plans, first aid, and proper use of fire extinguishers. Emergency contact information should be readily available on the worksite, and workers should be aware of the nearest medical facilities. By implementing these safety measures, employers can create a safe working environment for workers during steel rail maintenance, reducing the risk of accidents and ensuring the health and well-being of their employees.

- Q: What is the expected maintenance interval for steel rails?

- The expected maintenance interval for steel rails varies depending on various factors such as usage, climate, and track conditions. However, on average, steel rails are typically inspected and maintained every 3 to 5 years to ensure their safety, durability, and proper functioning.

- Q: Are steel rails affected by heavy snowfall or icy conditions?

- Yes, steel rails can be affected by heavy snowfall or icy conditions. Snow and ice can accumulate on the rails, making them slippery and reducing traction for trains. This can impact the braking and acceleration abilities of trains, potentially leading to delays or accidents. Additionally, the weight of heavy snow can put stress on the rails, causing them to bend or break. Therefore, it is crucial for rail operators to take measures such as snow removal and de-icing to ensure safe and efficient train operations during winter weather conditions.

- Q: What are steel rails?

- Steel rails are long, narrow bars made of steel that are used as tracks for trains and other rail vehicles.

- Q: Do steel rails require regular inspections?

- Indeed, regular inspections are essential for steel rails. They play a crucial role in guaranteeing the safety and soundness of railway tracks. These inspections serve the purpose of identifying any potential problems that may arise, such as cracks, wear, or damage in the steel rails. Trained personnel can carry out visual inspections, or advanced technologies like ultrasonic testing or track geometry measurement systems can be employed. Through these routine inspections, railway authorities can take proactive measures to address any issues promptly, performing necessary maintenance or repairs in order to prevent accidents or derailments. Moreover, regular inspections contribute to prolonging the lifespan of steel rails and ensuring the smooth and efficient functioning of train operations.

- Q: How do steel rails handle track buckling caused by thermal expansion?

- Various measures are implemented to handle track buckling caused by thermal expansion in steel rails. One primary approach involves incorporating expansion joints along the track to allow for rail expansion and contraction without causing buckling or warping. These joints are inserted at regular intervals to provide the necessary flexibility for the rails. Furthermore, the design and construction of rail tracks take into account the potential impact of thermal expansion. Fasteners are used to anchor the rails to the track bed, allowing for some degree of movement. This helps absorb the forces generated by thermal expansion and contraction, reducing the risk of buckling. The quality and composition of the steel used in rail construction also play a crucial role in managing track buckling. High-quality steel with appropriate tensile strength and resistance to thermal expansion is carefully selected to ensure the rails can withstand temperature fluctuations. Modern steel rails often meet specific standards and undergo rigorous testing to ensure effective handling of thermal expansion. Regular maintenance and inspection of rail tracks are also essential in preventing and addressing track buckling. By monitoring the condition of the tracks, any signs of buckling or warping can be detected early, allowing for timely rectification. In conclusion, steel rails are designed and engineered to effectively handle track buckling caused by thermal expansion. The inclusion of expansion joints, the use of flexible fasteners, the selection of high-quality steel, and regular maintenance all contribute to ensuring safe and reliable train operations in the face of thermal expansion challenges.

- Q: What is the role of steel rails in ensuring train stability?

- Steel rails play a crucial role in ensuring train stability as they provide a solid foundation for the train to travel on. The weight of the train is distributed evenly across the steel rails, which helps to maintain balance and prevent the train from derailing. One of the main functions of steel rails is to guide the train and keep it on track. The rails are designed to have a specific shape, with a flange on the inside of the railhead, which fits into the groove of the train's wheels. This flanged wheel-rail interaction helps to keep the train aligned and prevents it from deviating off the track. Furthermore, steel rails provide a smooth and continuous surface for the train to move on. This reduces the friction between the train's wheels and the rails, allowing the train to travel at high speeds with minimal resistance. This smooth surface also helps to minimize vibrations and bumps, providing a comfortable ride for passengers. In addition to stability, steel rails also contribute to the overall safety of train operations. They are designed to withstand heavy loads and provide resistance against wear and tear. Regular maintenance and inspection of the rails ensure that any defects or damages are promptly identified and repaired, preventing accidents and ensuring the safe passage of trains. Overall, steel rails are essential for train stability as they guide the train, distribute its weight, reduce friction, and provide a safe and smooth surface for the train to travel on. Without steel rails, trains would struggle to maintain stability and safety, making them an indispensable component of railway infrastructure.

Send your message to us

Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches