Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Ms Light Steel Rail Q235, 55Q

Production Standard: GB11264-89

Material: Q235, 55Q

Grade | Element(%) | ||||

C | Mn | S

| P

| Si

| |

Q235 |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

55Q | 0.50—0.60 | 0.70—1.00 | ≤0.050 | ≤0.045 | 0.15-0.35 |

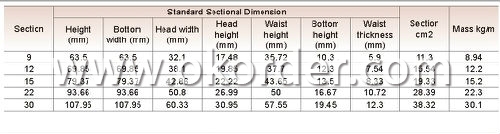

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6M, 8M, 10M, 12M or as the requriement

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Ms Light Steel Rail Q235, 55Q

Light Steel Rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line, for example:

railway, subway, transportation track, express, curve way, tunnel way.

Package & Delivery of Ms Light Steel Rail Q235, 55Q

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Light Steel Rail Q235, 55Q

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Light Steel Rail Q235, 55Q

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: What are the maintenance costs associated with steel rails?

- The costs of maintaining steel rails can differ based on various factors, such as the type of rail, location, and frequency of usage. Nonetheless, there are generally several common maintenance costs linked to steel rails. One primary cost is rail grinding. As time goes by, steel rails may develop irregularities like surface cracks or wear, which can impact train performance and the smoothness of the rail. Rail grinding involves removing these irregularities to maintain optimal rail conditions. The cost of rail grinding varies based on the length of the rail network and the frequency of grinding required. Another significant cost is rail replacement. Steel rails have a limited lifespan and will eventually need replacement due to wear and tear. The cost of rail replacement includes purchasing new rails, labor for installation, and any associated track work. The frequency of rail replacement depends on factors such as traffic volume and the quality of maintenance practices. Furthermore, regular inspections and maintenance are necessary to ensure safe and efficient rail operations. These activities involve inspecting rails for defects, lubricating them, and making adjustments to rail alignment or fasteners. The cost of these inspections and maintenance can vary depending on the rail network's size and complexity. Additionally, external factors like extreme weather conditions or heavy usage can increase maintenance costs. For example, severe weather events such as hurricanes or heavy snowfall may require additional maintenance efforts to repair damages or ensure rail infrastructure safety. In conclusion, maintaining steel rails includes costs like rail grinding, rail replacement, regular inspections, and maintenance activities. These costs depend on factors such as rail type, location, and frequency of usage. Rail operators must allocate sufficient resources to maintenance to ensure the rail network operates safely and efficiently.

- Q: Can steel rails be used in temporary track installations?

- Yes, steel rails can be used in temporary track installations. Steel rails are commonly used in various types of railway track installations, including both permanent and temporary setups. They are durable, strong, and provide stability to the tracks, making them suitable for temporary track installations as well.

- Q: What are the common causes of rail failures in steel rails?

- The common causes of rail failures in steel rails can be attributed to factors such as excessive wear and fatigue, improper maintenance, manufacturing defects, and external factors like extreme temperature changes and heavy loads. These issues can lead to rail cracks, fractures, and breaks, compromising the structural integrity of the rail and posing safety risks.

- Q: What are the benefits of using steel rails over other materials?

- Using steel rails in various applications has several advantages. Firstly, steel rails are highly durable and have a long lifespan. The strength and robustness of steel enable it to withstand heavy loads, extreme weather conditions, and constant wear and tear. As a result, steel rails require less maintenance and replacement, leading to cost savings in the long run. Secondly, steel rails offer excellent safety and stability. The strength of steel allows for the construction of secure and sturdy rail tracks, which are essential for ensuring the safety of trains and passengers. Steel rails also have superior resistance to deformation and buckling under heavy loads, reducing the risk of accidents or derailments. Additionally, steel rails have high conductivity, making them ideal for electrical systems such as railway signaling and electrification. Steel's electrical conductivity facilitates efficient transmission of electrical signals and power, ensuring reliable and prompt communication between trains and control centers. Moreover, steel rails provide versatility in terms of design and construction. They can be easily shaped and formed into various profiles and lengths, allowing for customization according to specific requirements. Steel rails can also be easily welded or joined, facilitating the construction of intricate rail networks or modifications to existing tracks. Furthermore, steel is a sustainable and eco-friendly material. It is fully recyclable, and the steel industry has made significant progress in reducing its carbon footprint. By opting for steel rails, the transportation sector can contribute to a greener and more sustainable future. In conclusion, the utilization of steel rails offers numerous benefits, including durability, safety, conductivity, versatility, and sustainability. These advantages make steel rails the preferred choice in various applications, particularly in railway systems, ensuring efficient, reliable, and safe transportation.

- Q: Do steel rails require regular lubrication?

- No, steel rails do not require regular lubrication.

- Q: How are steel rails protected from damage?

- Steel rails are protected from damage through various methods such as regular inspection and maintenance, applying protective coatings, ensuring proper alignment and support, and implementing measures like using rail pads and proper ballast.

- Q: How are steel rails used in railway signaling systems?

- Steel rails are a crucial component of railway signaling systems as they play a significant role in ensuring the safe and efficient operation of trains. These rails are used to provide a continuous and stable track for trains to travel on, while also serving as electrical conductors for various signaling functions. One of the primary uses of steel rails in railway signaling systems is for track circuits. Track circuits are electrical circuits that detect the presence of trains on the track and provide crucial information to the signaling system. They work by dividing the track into electrical sections using insulated joints, with each section having its own electric current flowing through it. When a train passes over a particular section of the track, it shunts the electric current, causing a change in electrical resistance. This change is detected by the signaling system, allowing it to determine the train's presence and location. Steel rails act as the electrical conductor for these track circuits, ensuring the smooth flow of current throughout the system. Furthermore, steel rails are also used for signaling power supply. In many railway signaling systems, electrical power is supplied to various signaling equipment and devices through the rails. This is achieved by utilizing the steel rails as a return path for the electrical current, completing the circuit and powering the signaling equipment. This method eliminates the need for separate electrical cables, reducing installation complexity and costs. Moreover, steel rails are utilized for trackside signaling equipment installation. Various signaling devices such as signals, point machines, and track circuits are mounted on or adjacent to the steel rails. These devices are crucial for providing information and commands to train drivers and controlling the movement of trains. By securely attaching signaling equipment to the steel rails, proper alignment and positioning are ensured, allowing accurate and reliable communication between the signaling system and the trains. In summary, steel rails are integral to railway signaling systems, facilitating the safe and efficient operation of trains. They serve as electrical conductors for track circuits, enabling the detection of trains and their location. Steel rails also act as a return path for signaling power supply, reducing the need for separate cables. Additionally, they provide a sturdy platform for mounting and positioning trackside signaling equipment.

- Q: What are the safety regulations for steel rail installation?

- The safety regulations for steel rail installation are designed to ensure the proper and secure installation of steel rails to prevent accidents and promote the safety of both railway workers and the general public. Some of the key safety regulations for steel rail installation include: 1. Site Inspection: Before installation, a thorough inspection of the site should be conducted to identify any potential hazards or obstacles that may affect the installation process. This includes assessing the terrain, soil conditions, and any nearby structures or utilities. 2. Proper Equipment: The use of appropriate equipment is crucial to maintain safety during rail installation. This includes specialized machinery such as cranes, track tamping machines, and rail fastening systems, which should be inspected regularly to ensure they are functioning correctly. 3. Personal Protective Equipment (PPE): All workers involved in rail installation must wear appropriate PPE, including hard hats, safety glasses, high-visibility clothing, steel-toed boots, and gloves. This is to protect them from potential hazards such as falling objects, flying debris, or accidental contact with machinery. 4. Training and Certification: Workers involved in steel rail installation should undergo comprehensive training on safety procedures and be certified to operate specific equipment. Regular refresher courses should also be conducted to ensure workers are up to date with the latest safety protocols. 5. Traffic Management: When installing steel rails near roadways or pedestrian areas, proper traffic management measures should be implemented to redirect or control traffic flow and ensure the safety of both workers and the public. This may include the use of barriers, warning signs, and flaggers. 6. Communication and Coordination: Effective communication and coordination between all parties involved in the rail installation project are vital to ensure safety. This includes regular meetings, clear instructions, and the use of radios or other communication devices to relay important information. 7. Quality Control: Regular inspections and testing of the installed steel rails should be conducted to ensure they meet the required standards and are securely fastened. This includes checking for defects, proper alignment, and adequate stability to prevent derailments or accidents. It is important to note that safety regulations for steel rail installation may vary depending on the country, region, or specific railway authority. Therefore, it is essential to consult the relevant local regulations and guidelines to ensure compliance with the specific safety requirements in a particular jurisdiction.

- Q: Can steel rails be bent or shaped to fit different track designs?

- Yes, steel rails can be bent or shaped to fit different track designs. Steel is a highly malleable material, which means it can be easily bent, twisted, or shaped without breaking. Rail manufacturers have the capability to customize steel rails, allowing them to be shaped according to specific track designs. This flexibility in shape allows for the creation of curved tracks, switches, and various other track configurations. Specialized equipment, such as hydraulic presses, are used to apply controlled pressure and shape the steel rails. However, it is important to note that the bending process must be carried out carefully and precisely to ensure the rails maintain their structural integrity and can safely support the weight of trains.

- Q: How are steel rails protected against buckling?

- Steel rails are protected against buckling through a combination of factors such as proper design and construction techniques, regular maintenance, and monitoring systems. One common approach is the use of continuous welded rails (CWR) which reduce the number of joints and increase the stability of the track. Additionally, the rails are often placed on a stable and well-constructed foundation, minimizing the risk of buckling. Regular inspections and maintenance help identify any potential issues and allow for timely repairs or replacements. Monitoring systems such as track circuits or temperature sensors are also employed to detect abnormal conditions, enabling prompt interventions to prevent buckling.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords