Ms Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

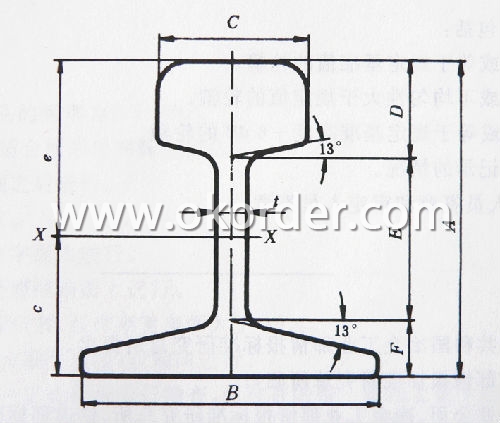

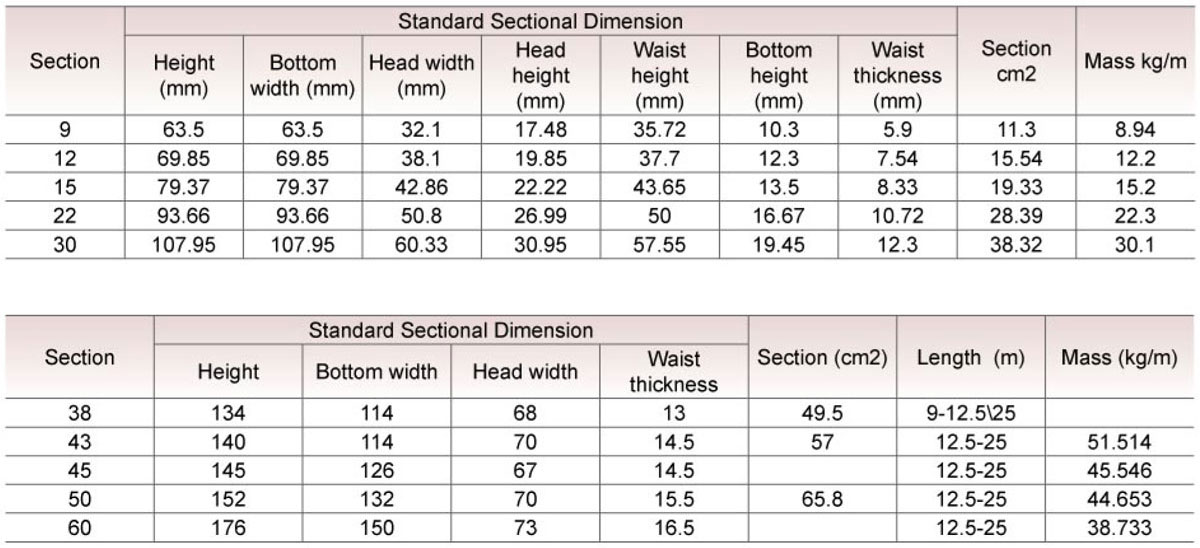

Specifications of Ms Steel Rail

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260, etc.

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Ms Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Ms Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Ms Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: How are steel rails protected from damage caused by earthquakes?

- To protect steel rails from earthquake damage, a combination of design and construction techniques is employed. One of the primary methods used involves incorporating flexible joints between rail sections. These joints enable independent movement of the rails during an earthquake, thereby reducing stress and strain on the track. Moreover, the use of resilient materials like rubber pads or neoprene bearings helps absorb and dissipate seismic energy, preventing its transmission to the rails. In addition, proper alignment and ballast support are vital for earthquake-resistant rail construction. Regular inspection and maintenance of the track are crucial to identify any potential weaknesses or issues that could be exacerbated by seismic activity. Implementing preventive measures like reinforcing the rail bed with compacted gravel or concrete further enhances the track's resilience. In certain cases, advanced technologies are utilized to provide additional protection for steel rails against earthquakes. Seismic sensors can be installed along the track to detect ground movements and initiate automatic responses, such as reducing train speeds or halting services altogether during high-intensity earthquakes. Overall, a combination of flexible joints, resilient materials, regular maintenance, and advanced technologies are essential in preserving the integrity and stability of rail infrastructure against earthquake damage. These measures ensure the safe and efficient operation of trains, even in regions prone to seismic activity.

- Q: How are steel rails affected by electromagnetic interference?

- Steel rails are generally not significantly affected by electromagnetic interference (EMI). This is because steel is a highly conductive material that can effectively shield against electromagnetic radiation. Steel rails used in railway tracks act as a natural barrier, preventing the penetration of electromagnetic waves and reducing the impact of EMI. However, it is important to note that there are certain situations where EMI might still have a minor effect on steel rails. For instance, if there is a strong and nearby source of electromagnetic radiation, such as high-voltage power lines or telecommunication towers, it could potentially induce some small electrical currents on the surface of the steel rail. These induced currents are known as "eddy currents." Eddy currents can cause some heating and energy loss in the steel rails. However, the magnitude of these effects is generally minimal and does not pose a significant risk to railway operations or safety. Moreover, modern rail designs and materials have been optimized to minimize the impact of EMI, further reducing any potential adverse effects. In summary, while steel rails can be subject to minor electromagnetic interference, their high conductivity and natural shielding properties make them relatively immune to significant negative impacts from EMI.

- Q: How are steel rails inspected for wear patterns?

- Steel rails are inspected for wear patterns using various methods such as visual inspections, ultrasonic testing, and measurements of rail profiles. Visual inspections involve examining the rail surface for visible signs of wear, including surface cracks, spalling, and irregularities. Ultrasonic testing is used to detect internal defects, such as cracks and voids, by sending high-frequency sound waves through the rail and analyzing the reflected signals. Rail profiles are also measured to ensure they meet the required specifications and to identify any abnormal wear patterns that may affect rail integrity. Overall, a combination of these methods is employed to effectively inspect steel rails for wear patterns.

- Q: What are the environmental impacts of steel rails?

- Steel rails have several environmental impacts. The production process of steel rails requires significant amounts of energy and raw materials, contributing to greenhouse gas emissions and resource depletion. Additionally, the extraction of iron ore and other materials for steel production can have detrimental effects on ecosystems, such as deforestation and habitat destruction. Furthermore, the transportation and installation of steel rails require fossil fuels, contributing to air pollution and carbon emissions. However, steel rails are durable and can be recycled, reducing the overall environmental impact compared to other materials.

- Q: Are steel rails affected by seismic activities or ground movements?

- Yes, steel rails can be affected by seismic activities or ground movements. Seismic activities, such as earthquakes, can cause ground shaking and ground displacement, which can lead to the misalignment or damage of steel rails. Ground movements, such as landslides or subsidence, can also impact the stability and alignment of steel rails, potentially causing derailments or track failures. Therefore, it is important to consider these factors when designing and maintaining railway infrastructure in seismic-prone areas.

- Q: How are steel rails affected by changes in train weights?

- Steel rails are affected by changes in train weights in various ways. As the weight of the train increases, the rails experience more stress and strain, leading to increased wear and tear. Heavier trains can cause the rails to deform or bend, resulting in track irregularities and potential derailments. Additionally, increased train weights can require stronger rail materials or additional maintenance to ensure the rails can withstand the added pressure.

- Q: What is the impact of steel rails on train energy consumption?

- Steel rails have a significant impact on train energy consumption as they provide a smooth and durable surface for trains to travel on. The low friction between the steel rail and train wheels reduces rolling resistance, allowing trains to move more efficiently and consume less energy. Additionally, steel rails offer stability and support, reducing the need for excessive braking and acceleration, further reducing energy consumption. Overall, steel rails play a crucial role in improving the energy efficiency of trains.

- Q: What are the different types of steel rail maintenance vehicles?

- There are several types of steel rail maintenance vehicles, including rail grinders, rail inspection cars, rail welding machines, and track maintenance vehicles.

- Q: How are steel rails inspected for rail head defects?

- Steel rails are inspected for rail head defects through various methods, including visual inspections, ultrasonic testing, and magnetic particle testing. Visual inspections involve closely examining the rail head for any visible cracks, wear, or other abnormalities. Ultrasonic testing uses sound waves to detect internal defects by sending high-frequency waves through the rail and analyzing the echoes. Magnetic particle testing involves applying a magnetic field to the rail and inspecting it for any magnetic particles that indicate surface or near-surface defects. These inspections help ensure the safety and integrity of steel rails.

- Q: Can steel rails be used for subways or metro systems?

- Yes, steel rails are commonly used for subways or metro systems. Steel rails provide durability, strength, and stability, making them suitable for heavy train traffic and supporting the weight of the trains.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords