Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Product Advantages:

OKorder's Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

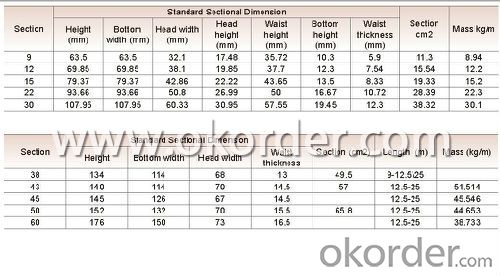

Specifications of Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines:

Product Name: Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

Packaging & Delivery of Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Invoicing on theoretical weight or actual weight as customer request

8. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can fit in the containers of 20inches the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How are steel rails affected by train derailments?

- Steel rails can be significantly affected by train derailments. When a train derails, the force and impact of the accident can cause a range of damages to the steel rails. The most common damage is the bending or warping of the rails, which can result in misalignment or even complete detachment from the track. This can lead to disruptions in the train service and pose serious safety risks. In addition to bending or warping, train derailments can also cause the steel rails to crack or break. The excessive forces exerted during a derailment can exceed the rail's structural capacity, leading to fractures or complete failures. These breaks in the rails can further contribute to the derailment and subsequent damage to the train and infrastructure. Furthermore, the intense friction and dragging of train wheels against the rails during a derailment can cause severe wear and tear on the steel rails. This can result in the formation of grooves or indentations, which may compromise the smoothness and stability of the track. These deformations can affect the train's ability to maintain proper alignment and increase the risk of future derailments. It is worth noting that the extent of damage to steel rails during a derailment can vary depending on numerous factors, including the speed and weight of the train, the angle and force of impact, and the condition of the rails themselves. Following a derailment, thorough inspections and repairs are necessary to identify and rectify any damages to the steel rails to ensure the safety and efficiency of train operations.

- Q: Can steel rails be used in urban transit systems?

- Urban transit systems can indeed utilize steel rails. In fact, steel rails have long been the favored option for urban transit systems across the globe. There are several advantages that make steel rails perfect for urban transit systems. To begin with, steel rails offer a smooth and stable track for trains or trams to traverse. This smoothness guarantees a comfortable experience for passengers, minimizing vibrations and reducing the chances of accidents or derailments. Additionally, steel rails provide excellent traction, enabling trains to accelerate and decelerate efficiently, a crucial aspect in urban areas where frequent stops and starts are common. Furthermore, steel rails are exceptionally durable and can handle heavy loads and continuous use. This is especially important in urban transit systems where trains or trams run frequently and carry large numbers of passengers. Steel rails have a long lifespan and require minimal maintenance, making them a cost-effective choice for urban transit infrastructure. In addition, steel rails can be easily integrated into existing urban landscapes. They can be laid on existing roadways or embedded in concrete, minimizing the need for extensive construction work and disruptions to the surrounding areas. Moreover, steel rails have a smaller footprint compared to other track materials, allowing for efficient utilization of limited urban space. Moreover, steel rails have proven to be highly reliable and safe in urban transit systems. They have a successful track record in cities worldwide, ensuring the smooth operation of public transportation networks. Steel rails also contribute to the overall efficiency of urban transit systems by reducing traffic congestion and offering a sustainable transportation alternative. In conclusion, steel rails are a well-established and suitable option for urban transit systems. Their smoothness, durability, and reliability make them perfect for providing safe and efficient transportation in densely populated urban areas. The use of steel rails in urban transit systems has been proven effective and advantageous, contributing to the development of sustainable and modern transportation networks.

- Q: Can steel rails be used in railway systems with limited track alignment options?

- Yes, steel rails can be used in railway systems with limited track alignment options. Steel rails are commonly used in railway systems worldwide due to their durability, strength, and versatility. They can be easily adapted to different track alignments, including those with limited options. Railway systems with limited track alignment options often face challenges in terms of space constraints, terrain variations, or existing infrastructure. However, steel rails can be manufactured in various shapes, sizes, and configurations to suit these specific requirements. They can be bent, curved, or configured to fit tight turns, steep gradients, or irregular track alignments. Additionally, steel rails have high load-bearing capacity, which allows them to support heavy train traffic and withstand the stresses and strains imposed by moving trains. This makes them suitable for railway systems with restricted track alignment options, where the tracks may need to be laid in challenging terrains such as mountains, urban areas, or areas with limited space. Moreover, steel rails offer efficient and smooth train operations, as they provide a stable and secure platform for trains to run on. They minimize vibrations, reduce noise levels, and ensure a comfortable ride for passengers. This is particularly important in railway systems with limited track alignment options, as it helps to mitigate the impact on surrounding areas and enhance the overall efficiency and reliability of the system. In conclusion, steel rails can indeed be used in railway systems with limited track alignment options. Their adaptability, durability, and strength make them a suitable choice for such scenarios, allowing for the construction of efficient and reliable railway networks even in challenging terrains or space-constrained areas.

- Q: What are the different types of steel rail fastening systems?

- There are several types of steel rail fastening systems used in railway tracks including elastic rail clips, fishplates, rail bolts, rail pads, and rail anchors.

- Q: Can steel rails be used in shared rail corridors with other transportation modes?

- Yes, steel rails can be used in shared rail corridors with other transportation modes. Steel rails are commonly used in railways due to their durability and ability to withstand heavy loads. In shared rail corridors, steel rails can be integrated with other transportation modes such as light rail, trams, or freight trains, allowing for efficient and safe transportation of both passengers and goods.

- Q: How do steel rails contribute to train ride quality?

- Train ride quality is enhanced by steel rails in several ways. Firstly, the smooth and stable surface they provide allows the train to run smoothly. The design and manufacturing of steel rails guarantee their straightness and absence of deformities or irregularities. Consequently, the train wheels consistently make contact with the rails, resulting in reduced vibrations and a smoother ride. Moreover, steel rails possess remarkable strength and durability. They can withstand the heavy loads and constant impact of the train, maintaining their shape and integrity over time. This stability and strength contribute to a more comfortable and secure journey for passengers. In addition, steel rails play a vital role in maintaining the alignment and stability of the train. They are firmly fastened to the sleepers or ties, which are in turn fixed to the ground. This ensures that the tracks remain in place without shifting or moving during the train's motion. The stability of the tracks is crucial for a smooth and safe ride, as any misalignment or movement could cause discomfort for passengers. Furthermore, steel rails are specifically designed to reduce noise during train operations. The smooth surface and precise alignment of the rails minimize friction and noise generated as the train wheels roll over them. This contributes to a quieter and more enjoyable journey for passengers. In conclusion, steel rails are an indispensable element in enhancing train ride quality. They provide a smooth and stable surface, ensure alignment and stability, and reduce noise. As a result, passengers can experience a comfortable, secure, and enjoyable journey during train travel.

- Q: How are steel rails inspected for fatigue cracks?

- Steel rails are inspected for fatigue cracks using various techniques such as ultrasonic testing, magnetic particle inspection, and visual inspection. Ultrasonic testing involves sending high-frequency sound waves through the rail to detect any internal flaws or cracks. Magnetic particle inspection uses magnetic fields and magnetic particles to identify surface cracks. Visual inspection is also carried out by trained inspectors who visually examine the rail for any visible signs of fatigue cracks.

- Q: Are steel rails recyclable?

- Yes, steel rails are recyclable. Steel is a highly recyclable material, and steel rails can be melted down and reused to produce new steel products. Recycling steel rails not only helps conserve natural resources but also reduces the environmental impact associated with the production of new steel.

- Q: How are steel rails protected against track settlement?

- Various methods are employed to protect steel rails against track settlement. One commonly used approach involves the implementation of ballast, which consists of crushed stones or gravel that is placed beneath and around the rails. By offering stability and evenly distributing the weight of the trains, ballast prevents excessive settlement. To further safeguard against settlement, the rails themselves are designed to be sturdy and long-lasting, with appropriate spacing and alignment. This design ensures that the weight of the trains is evenly distributed along the entire length of the rails, thus minimizing the chances of settlement. Regular inspections and maintenance are also conducted to identify any signs of settlement or deformation. In certain instances, engineers may employ additional techniques such as under-sleeper pads or resilient fasteners to enhance protection against settlement. Under-sleeper pads are made of rubber or polyurethane and are placed between the rail and the sleeper. These pads help absorb vibrations and reduce the impact of settlement. On the other hand, resilient fasteners are specifically designed to allow some movement of the rail, compensating for settlement and reducing stress on the track structure. Overall, a combination of proper design, regular maintenance, and the use of ballast, under-sleeper pads, and resilient fasteners effectively safeguard steel rails against track settlement. These measures are crucial for maintaining the safety and stability of the tracks, reducing the risk of derailments, and ensuring smooth and efficient rail operations.

- Q: What are the safety precautions when working with steel rails?

- When working with steel rails, it is important to follow several safety precautions. Firstly, wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots is essential to protect against potential hazards. Secondly, workers should be trained on proper handling techniques to avoid strains and injuries. It is crucial to use lifting equipment and proper body mechanics when moving heavy rails to prevent back injuries. Additionally, workers should be cautious of sharp edges and potential tripping hazards, ensuring a clean and organized work area. Finally, regular inspections and maintenance of the rails, including checking for any cracks or defects, should be conducted to ensure safe working conditions.

Send your message to us

Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords