Steel Heavy Rail with High Quality for Structure Project and Building

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

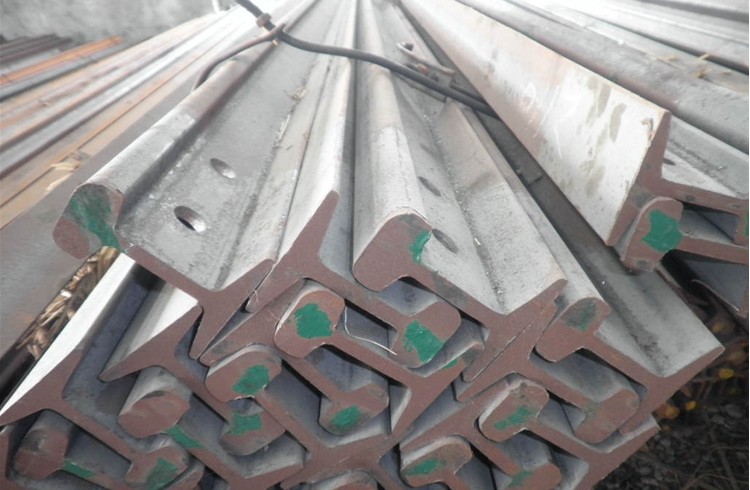

Product Description of Steel Heavy Rail with High Quality for Structure Project and Building:

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Steel Heavy Rail with High Quality for Structure Project and Building:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Heavy Rail with High Quality for Structure Project and Building:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Heavy Rail with High Quality for Structure Project and Building:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q: How are steel rails protected from excessive noise?

- Steel rails are protected from excessive noise through the use of various methods, such as installing vibration-damping pads or resilient fasteners between the rails and the sleepers to absorb and reduce noise vibrations. Additionally, rail dampers and insulated rail joints are also utilized to minimize noise generated by train movements.

- Q: What are the different types of steel rail fastening systems?

- There are several types of steel rail fastening systems used in railway tracks including elastic rail clips, fishplates, rail bolts, rail pads, and rail anchors.

- Q: What are the factors that determine the lifespan of steel rails?

- The factors that determine the lifespan of steel rails include the quality of the steel used, the level of maintenance and inspection, the amount and type of traffic on the rails, and environmental factors such as temperature, humidity, and exposure to corrosive substances.

- Q: Are steel rails prone to wear and tear?

- Yes, steel rails are prone to wear and tear over time due to the constant heavy loads and friction from train wheels. This can lead to various forms of deterioration, such as surface wear, pitting, cracking, and deformation. Regular maintenance and inspection are crucial to ensure the safety and efficiency of railways.

- Q: What are the different types of rail switches used with steel rails?

- 1. The commonly used rail switches with steel rails include turnouts, also known as switches or points. These switches consist of movable rails that divert trains from one track to another, typically at junctions or merge/diverge points. 2. Another type of rail switch used with steel rails is the crossover. Crossovers allow trains to move from one track to a parallel track, providing flexibility in train operations. They are often used for bypassing track sections or accessing different platforms. 3. Diamond crossings are rail switches that allow trains to cross each other at junctions without curved tracks. They have a diamond-shaped layout, with two tracks intersecting diagonally. Diamond crossings are commonly found in complex rail networks with multiple line intersections. 4. Slip switches, also known as catch points or derailers, are used to prevent trains from accidentally entering out-of-service or maintenance tracks. They have movable rails that align to divert trains onto a separate track or into a safe area. Slip switches are crucial safety features in rail infrastructure. 5. Gauntlet tracks are used in limited space or urban areas. They consist of overlapping tracks that enable trains to pass in opposite directions on a shared track section. Gauntlet tracks are often employed when constructing separate tracks for each direction is not feasible. These examples showcase the various rail switches used with steel rails. Each type serves a specific purpose, ensuring flexibility and safety in train operations. The selection of rail switches depends on the specific requirements of the rail network and installation location.

- Q: Can steel rails be used for transport systems in amusement parks?

- Yes, steel rails can be used for transport systems in amusement parks. Steel rails are commonly used in amusement parks for roller coasters and other types of rides that require a track system. Steel rails offer durability, strength, and smoothness, making them ideal for transporting passengers safely and providing a thrilling experience.

- Q: What is the process of replacing damaged steel rails in emergency situations?

- In emergency situations, the process of replacing damaged steel rails typically involves a series of steps. Firstly, the damaged section of the rail is identified and marked for replacement. Next, the rail is cut and removed using specialized tools and equipment. Simultaneously, any broken or weakened rail fastenings are replaced to ensure proper stability. Once the damaged rail is removed, a new rail section is prepared and aligned with the existing track. This involves ensuring the correct length and alignment to maintain the integrity of the rail line. The new rail is then securely fastened to the track using bolts or other appropriate fastening methods. Finally, the track is inspected and tested to ensure it is safe for train operations before it is reopened for use.

- Q: How are steel rails protected against track ballast degradation?

- Steel rails are protected against track ballast degradation through a variety of methods. One common method is the use of a protective layer called ballast mats or geotextiles. These mats are made of a durable material, such as rubber or synthetic fibers, and are placed between the ballast and the steel rails. They act as a barrier, preventing the ballast from getting into direct contact with the rails, thus reducing the risk of degradation. Additionally, regular maintenance practices such as tamping and re-surfacing the ballast help to prevent its degradation. Tamping involves compacting the ballast to ensure it remains stable and provides proper support to the rails. Re-surfacing involves replacing worn-out or degraded ballast with fresh material, maintaining its integrity and preventing further degradation. Furthermore, drainage systems are installed to prevent water accumulation in the ballast. Water can accelerate the degradation process by weakening the ballast, causing it to become loose or prone to erosion. Proper drainage systems, such as ditches or pipes, help to redirect water away from the track, keeping the ballast dry and stable. Lastly, regular inspections are conducted to identify any signs of ballast degradation. If any issues are detected, prompt repairs or replacements are made to maintain the integrity of the ballast and protect the steel rails. These measures collectively help to protect steel rails against track ballast degradation, ensuring the safety and longevity of railway tracks.

- Q: What is the process of installing steel rails on bridges?

- The process of installing steel rails on bridges involves several steps. Firstly, a detailed survey and inspection of the bridge is conducted to assess its condition and determine the type and length of steel rails required. This information is crucial for ensuring the rails meet the necessary specifications and can withstand the expected loads and stresses. Next, the existing railings or guardrails on the bridge are removed, creating a clear space for installing the new steel rails. The removal process may involve cutting, unscrewing, or dismantling the existing railings, depending on their design and attachment method. Once the area is clear, the steel rails are brought to the bridge site. These rails are typically pre-fabricated sections that are designed to fit together seamlessly. The rails are often delivered in sections that are easily manageable and can be transported to the installation location. The rails are then positioned along the edge of the bridge, aligning them with the pre-marked locations. In some cases, temporary support structures or brackets may be used to hold the rails in place temporarily while the installation process continues. These supports ensure that the rails remain stable and secure during the installation. After the rails are positioned, they are anchored to the bridge structure using bolts or other fastening mechanisms. These fasteners are inserted through pre-drilled holes in the rails and are secured to the bridge to provide a strong and durable connection. Once the rails are securely anchored, they are inspected for any defects or inconsistencies. If any issues are found, necessary adjustments or repairs are made to ensure the rails meet the required standards and regulations. Finally, the installation process is completed by conducting a thorough inspection of the entire rail system to ensure it is properly aligned, securely fastened, and meets all safety requirements. This inspection may involve using specialized tools and equipment to measure the alignment, stability, and integrity of the rails. Overall, the process of installing steel rails on bridges requires careful planning, precise measurements, and skilled labor to ensure a safe and effective installation.

- Q: What are the different types of steel rail track maintenance machines?

- There are several types of steel rail track maintenance machines, including rail grinders, rail milling machines, rail tamping machines, and rail welding machines. Each of these machines serves a specific purpose in maintaining the track's integrity and ensuring smooth and safe train operations.

Send your message to us

Steel Heavy Rail with High Quality for Structure Project and Building

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches