Hot Rolled Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

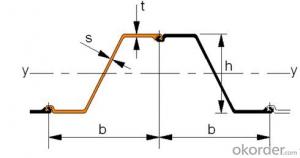

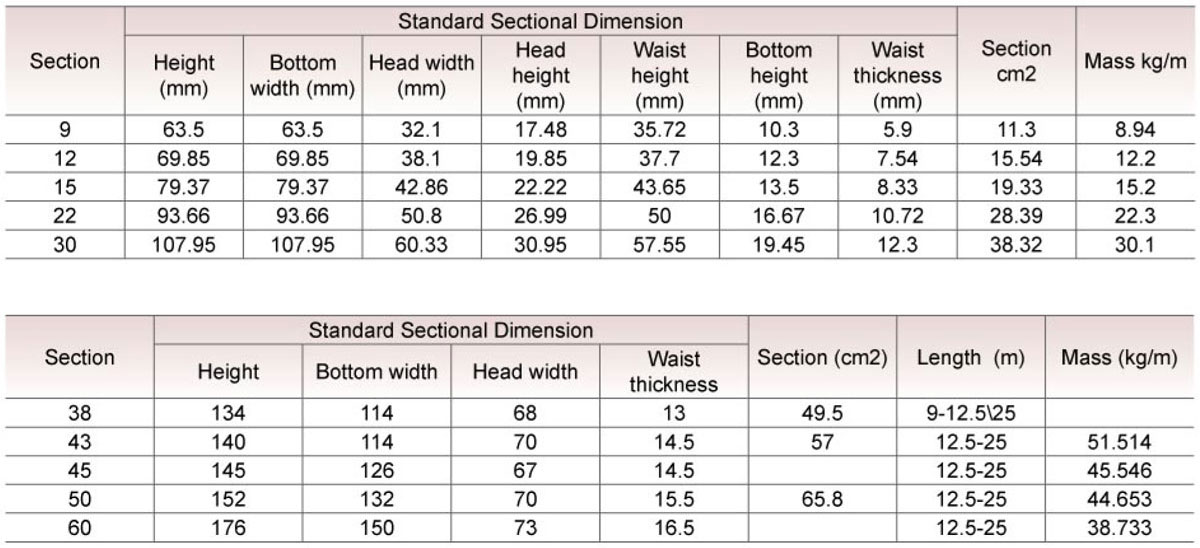

Specifications of Hot Rolled Steel Rail

Production Standard: GB Standard, AREMA, BS, UIC860, JIS, DIN, etc

Grade: Q235B, 55Q, 900A, 50Mn, U71Mn

| Alloy No. | Grade | C | Mn | S | P | Si |

| Q235 | B | 0.12%-0.20 | 0.3%-0.7% | <=0.045% | <=0.045% | <=0.3% |

Length: 6M, 8M, 9M, 10M, 12M, 12.5M, 24M or as the requriements of the client

Sizes: 9kg-60kg

Usages of Hot Rolled Steel Rail

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Packaging & Delivery of Hot Rolled Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of Hot Rolled Steel Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: What are the standard lengths of steel rails?

- The specific application and country determine the varying standard lengths of steel rails. Nonetheless, in numerous countries, the customary length for railway track steel rails is generally 12 meters or 39.37 feet. This length is commonly utilized due to the convenient transportation, installation, and maintenance it offers. Moreover, shorter steel rail lengths, like 6 meters or 20 feet, may be employed for particular purposes or industries. It is important to mention that specialized applications or specific railway systems may have divergences in rail lengths.

- Q: What are the different types of rail crossings used with steel rails?

- There are mainly three types of rail crossings used with steel rails: level crossings, grade crossings, and pedestrian crossings. Level crossings are used to intersect roads or highways at the same level as the railway tracks. Grade crossings, on the other hand, involve a slight incline or decline where the road crosses the tracks. Pedestrian crossings are designed specifically for pedestrians to safely cross the railway tracks.

- Q: What is the typical hardness of steel rails?

- The typical hardness of steel rails is around 200 to 300 Brinell hardness units (BHN).

- Q: How do steel rails handle changes in track alignment due to track settlement and longitudinal movement?

- Steel rails are designed to handle changes in track alignment caused by track settlement and longitudinal movement. The flexibility of steel allows the rails to adjust and accommodate these changes without compromising the stability and integrity of the track. The rails can undergo slight bending and flexing, which helps absorb the forces and maintain a smooth and safe ride for trains. Additionally, regular maintenance and monitoring of track conditions ensure any necessary adjustments or repairs are made to maintain proper alignment and prevent any potential issues.

- Q: How are steel rails protected against theft and unauthorized access?

- Steel rails are protected against theft and unauthorized access through various measures. One of the primary methods of protection is the implementation of security measures such as fencing and barriers. Steel rail tracks are often enclosed within secured perimeters, making it difficult for unauthorized individuals to gain access to the tracks. In addition to physical barriers, advanced surveillance systems are deployed to monitor rail tracks. These systems include CCTV cameras, motion sensors, and alarms that are strategically placed along the rail network. These surveillance systems help in detecting any suspicious activities and alerting the authorities in real-time. Furthermore, railways often collaborate with law enforcement agencies to ensure the security of steel rails. Regular patrolling and inspections are conducted to identify any potential vulnerabilities or signs of tampering. This proactive approach allows for swift action to be taken in case of any unauthorized access or theft attempts. To deter theft, steel rails are also marked with unique identification codes. These codes are registered and tracked, making it easier to trace stolen rails and apprehend the culprits. Additionally, some rail companies have implemented anti-theft technologies such as embedded GPS tracking devices in the steel rails, which further enhances the ability to locate stolen property. Overall, a combination of physical barriers, advanced surveillance systems, collaboration with law enforcement agencies, and the use of identification codes and tracking technologies help protect steel rails against theft and unauthorized access. These measures not only deter potential thieves but also ensure the safety and reliability of rail transportation systems.

- Q: Can steel rails be used in areas with extreme weather conditions?

- Indeed, areas with extreme weather conditions are compatible with the use of steel rails. Steel is renowned for its robustness and its capacity to endure challenging surroundings. It possesses the ability to withstand corrosion, a quality of utmost significance in regions characterized by high levels of humidity or close proximity to saltwater. Furthermore, steel rails exhibit a remarkable capability to withstand substantial loads and extreme fluctuations in temperature, rendering them suitable for areas exposed to severe weather patterns, including scorching heat or freezing cold. Nonetheless, it is imperative to conduct regular inspections and adhere to proper maintenance practices to ensure the safety and longevity of the steel rails in such areas.

- Q: How are steel rails connected to each other?

- Steel rails are connected to each other through a process called rail welding, where the ends of two rail sections are heated and fused together using intense heat and pressure.

- Q: Are steel rails affected by heavy rainfall or flooding?

- Yes, steel rails can be affected by heavy rainfall or flooding. Excessive moisture can lead to corrosion and erosion of the steel rails, compromising their structural integrity and potentially causing damage to the railway infrastructure.

- Q: What are the different types of rail anchors used with steel rails?

- The different types of rail anchors used with steel rails include dog spike anchors, screw spike anchors, spring spike anchors, and resilient rail anchors.

- Q: How are steel rails protected against fire hazards?

- Steel rails are typically protected against fire hazards through the application of fire-resistant coatings, such as intumescent paint or fire retardant materials. These coatings create a barrier that can withstand high temperatures and prevent the steel from reaching its ignition point. Additionally, fire suppression systems, such as water sprinklers or foam systems, may be installed to quickly extinguish any potential fires that could occur. Regular inspections and maintenance are also conducted to ensure the integrity of the fire protection measures.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Hot Rolled Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords