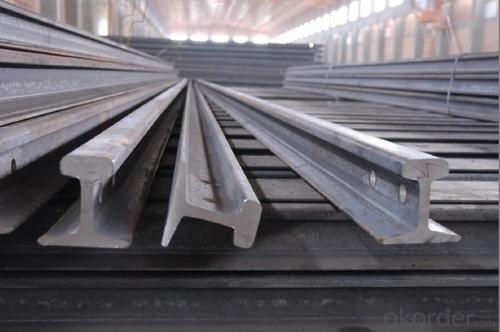

Mild Steel Light Rail 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Mild Steel Light Rail 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Steel Light Rail 55Q are ideal for structural applications and are widely used in forest region, Mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.etc.

Product Advantages:

OKorder's Mild Steel Light Rail 55Q are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q235, 55Q

Certificates: ISO, SGS, BV, CIQ

Length:6m, 12m,12.5m

Package: Packed in bundles and shipped by break bulk or containers.

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: Are steel rails affected by heavy loads or overloading?

- Yes, steel rails can be affected by heavy loads or overloading. Excessive weight can cause the steel rails to bend, warp, or even break, compromising the safety and integrity of the railway track. It is crucial to ensure that the loads carried by trains are within the safe limits prescribed by the railway authorities to prevent damage to the steel rails. Regular inspections and maintenance are also essential to identify and address any potential issues caused by heavy loads or overloading.

- Q: What are the different types of rail joints used in steel rail installation?

- There are several types of rail joints used in steel rail installation, including the butt joint, fishplate joint, and insulated joint. The butt joint involves aligning two rail ends and welding them together. The fishplate joint involves using a metal plate, called a fishplate or splice bar, to connect two rail ends by bolting them together. Insulated joints are used to create electrical separation between sections of track, preventing the flow of electric current. These different types of rail joints are chosen based on factors such as track conditions, design requirements, and the need for electrical isolation.

- Q: Can steel rails be repurposed for other applications?

- Yes, steel rails can be repurposed for other applications. They can be recycled and used in the construction industry for various purposes such as reinforcing concrete structures, creating barriers, or even as decorative elements. Additionally, they can be transformed into different shapes to serve as supports or frames for various applications, making them versatile and sustainable materials for repurposing.

- Q: Are steel rails used in freight train tracks?

- Yes, steel rails are commonly used in freight train tracks. Steel rails provide the necessary strength and durability to support the weight and movement of heavy freight trains. They are designed to withstand the constant impact and friction caused by the movement of train wheels, ensuring safe and efficient transportation of goods. Steel rails are known for their high tensile strength, which allows them to handle heavy loads and withstand the forces exerted by the moving trains. Additionally, steel rails have a long lifespan and require minimal maintenance, making them a cost-effective choice for freight train tracks. Overall, steel rails are essential components of freight train tracks, playing a crucial role in the transportation of goods across long distances.

- Q: What are the requirements for steel rail storage and handling?

- Steel rail storage and handling requirements can vary depending on specific circumstances and industry standards. However, there are typically followed general requirements to ensure the safety and proper handling of steel rails. 1. Adequate storage space is necessary for steel rail storage. The area must be clear of debris or obstructions and have a solid, flat surface to prevent rail bending or damage. Proper stacking with sufficient clearance between layers is important to prevent distortion or bending. 2. Steel rails should be stored in a dry, well-ventilated area to protect them from moisture and humidity. Excessive moisture exposure can lead to rust and corrosion, which weakens the rails over time. Protecting the rails from extreme temperatures and direct sunlight is also crucial as it can cause expansion or contraction, affecting their structural integrity. 3. Appropriate handling equipment is essential for safe transportation and storage of steel rails. This may include cranes, forklifts, or railcar movers, depending on rail size and weight. Trained personnel should operate and maintain the equipment to prevent accidents and rail damage. 4. Proper lifting techniques should be used when handling steel rails to prevent bending or distortion. Rails should be lifted evenly and supported throughout their length to avoid stress concentration points. Sharp or pointed objects should be kept away from the rails to prevent scratching or gouging. 5. Each steel rail should be marked and identified for traceability and easy identification. This may include rail type, size, and manufacturer's information. Proper labeling and documentation are essential for inventory management and quality control purposes. 6. Regular inspection and maintenance of steel rails are crucial to identify damage, wear, or corrosion. Any rails that do not meet required standards or show signs of defects should be promptly removed from service and replaced. In conclusion, steel rail storage and handling requirements involve creating a safe and suitable environment, using proper equipment and techniques, and ensuring regular inspection and maintenance. Following these requirements helps prolong rail lifespan, maintain their structural integrity, and prevent accidents or damage during storage and transportation.

- Q: How do steel rails contribute to the efficiency of railway systems?

- There are several ways in which steel rails contribute to the efficiency of railway systems. Firstly, steel is a very strong and durable material, allowing the rails to withstand heavy loads and constant wear and tear. This means that they can last for many years without requiring frequent replacement or repair, reducing maintenance costs and downtime. Secondly, the design of steel rails ensures that trains have a smooth and stable surface to travel on. The evenness of the rails helps to minimize vibrations and reduce friction between the wheels and the track, resulting in less energy being needed to propel the train forward. This not only improves the overall energy efficiency of the railway system but also enables trains to reach higher speeds, reducing travel times and increasing capacity. Additionally, steel rails are engineered with precise dimensions and alignment, ensuring safe and smooth travel for trains. This accuracy helps to prevent derailments and maintain train stability, enhancing the overall safety and reliability of the railway system. Moreover, steel rails are compatible with various signaling and control systems, allowing for efficient and precise train operation. These systems rely on the accurate positioning of trains on the tracks, which is facilitated by the consistent and well-maintained steel rails. Lastly, steel rails offer excellent resistance to corrosion, which is particularly important in areas with harsh weather conditions or exposure to moisture. The durability and resistance to corrosion of steel rails greatly reduce the need for frequent replacements, resulting in cost savings and improved efficiency for railway systems. In conclusion, steel rails play a crucial role in enhancing the efficiency of railway systems through their strength, durability, smoothness, precision, and resistance to corrosion. Their numerous advantages contribute to safer, faster, and more reliable train travel, ultimately improving the overall performance and effectiveness of railway systems.

- Q: How are steel rails protected from chemical damage?

- Steel rails are typically protected from chemical damage through the application of protective coatings and treatments. These coatings act as a barrier, preventing contact between the rail surface and potentially corrosive chemicals. Additionally, regular inspections and maintenance are conducted to identify and rectify any damage or corrosion that may occur over time.

- Q: How are steel rails protected against extreme temperatures?

- Steel rails are protected against extreme temperatures through a process called thermal expansion and contraction. Steel has a high coefficient of thermal expansion, so it expands and contracts with temperature changes. To accommodate this, gaps are left between individual rail sections, allowing them to expand and contract without buckling or warping. Additionally, rail materials are carefully chosen to withstand temperature variations and reduce the risk of damage.

- Q: Are steel rails more cost-effective than other materials?

- Steel rails are widely considered to be more cost-effective than other materials for several reasons. Firstly, steel is a highly durable material that can withstand heavy loads and extreme weather conditions, ensuring a longer lifespan compared to other options. This longevity minimizes the need for frequent replacements, reducing maintenance and replacement costs in the long run. Secondly, steel rails have excellent strength and resistance to wear and tear. They can handle the high stresses and strains associated with heavy train traffic, reducing the risk of rail failures and accidents. This reliability leads to lower operational costs, as there is less need for emergency repairs and service disruptions. Additionally, steel is a widely available material, making it relatively inexpensive compared to alternatives like concrete or composite materials. This availability and affordability of steel make it a cost-effective choice for rail infrastructure projects, especially when considering the large quantities of rail tracks required. Furthermore, steel rails offer flexibility in design and construction. They can be easily customized and modified to meet specific project requirements, allowing for efficient installation and integration into existing rail networks. This adaptability contributes to savings in terms of time, labor, and overall project costs. Lastly, steel rails have a proven track record of performance in the railway industry. They have been used for many years and have undergone extensive testing and research, ensuring their reliability and safety. This established reputation makes steel rails a trusted and cost-effective option for rail infrastructure projects. In conclusion, steel rails are generally considered more cost-effective than other materials due to their durability, strength, availability, flexibility, and proven performance. While initial costs may vary, the long-term benefits in terms of reduced maintenance, longer lifespan, and reliable performance make steel rails a preferred choice for rail infrastructure projects.

- Q: How do steel rails contribute to train stability?

- Train stability is enhanced by steel rails in multiple ways. Firstly, the presence of steel rails ensures a strong and durable track structure, enabling the train to operate smoothly and securely. The even distribution of the train's weight across the steel rails contributes to its balance and stability. Secondly, the steel rails act as a reliable guide for the train wheels, keeping them in proper alignment and preventing any sideways movement. This aspect serves to prevent the train from derailing and guarantees it stays on the intended path. Furthermore, the shape of the steel rails is also significant in maintaining train stability. The rails are meticulously designed with a specific profile, referred to as the "rail profile," which effectively keeps the train wheels centered on the track. This design diminishes any lateral forces acting on the train, thereby minimizing the risk of instability. Moreover, the sleek surface of the steel rails offers minimal friction for the train wheels, facilitating efficient movement and reducing the likelihood of skidding or slipping. This is particularly beneficial during times of acceleration, deceleration, and when navigating curves. In conclusion, steel rails play a vital role in ensuring train stability through their provision of a robust structure, guidance for the train wheels, and the reduction of lateral forces and friction.

Send your message to us

Mild Steel Light Rail 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords