High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

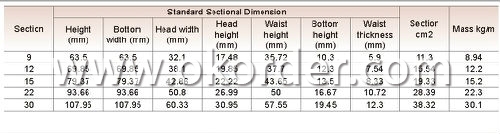

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Usages of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ

Q1: What is the normal tolerance of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20inches the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How are steel rails protected against excessive vibrations?

- Several methods are utilized to protect steel rails against excessive vibrations. Resilient fastenings or rail pads are one of the primary approaches employed. These materials are placed between the rail and the fastening system to absorb and dissipate vibrations generated by passing trains. By acting as a cushion, resilient fastenings reduce the impact and vibrations transmitted to the rail. Another technique involves the use of ballast, a layer of crushed stones beneath the railway tracks. This ballast functions as a shock absorber, absorbing vibrations and evenly distributing the load of passing trains. Its presence aids in stabilizing the rails and minimizing excessive vibrations. In order to prevent excessive vibrations, regular maintenance and inspection of the rails are crucial. Any defects, such as cracks or damaged sections, are promptly identified and repaired. By ensuring the rails are well-maintained, the risk of vibrations is minimized. Furthermore, the design of the rail system itself plays a vital role in mitigating excessive vibrations. The alignment, curvature, and elevation of the tracks are carefully planned to reduce the occurrence and impact of vibrations. Employing proper track design techniques, such as providing transition curves, also helps in minimizing the vibrations caused by train movements. Ultimately, a combination of resilient fastenings, ballast, regular maintenance, and thoughtful rail system design work together to safeguard steel rails against excessive vibrations, ensuring the safe and efficient operation of railways.

- Q: Can steel rails be used in areas with extreme weather conditions?

- Yes, steel rails can be used in areas with extreme weather conditions. Steel is a durable and strong material that can withstand harsh weather conditions such as extreme temperatures, heavy rains, snow, and strong winds. It is commonly used in railway tracks worldwide, including regions with extreme climates. However, regular maintenance and inspections are necessary to ensure the safety and longevity of steel rails in such areas.

- Q: What are the common problems associated with steel rails?

- There are several common problems associated with steel rails, which can affect the safety and efficiency of railways. One of the main issues is wear and tear caused by the constant contact between the steel rails and train wheels. Over time, this can lead to rail corrosion, deformation, and cracks. These defects can weaken the rails, causing them to become unstable and potentially leading to derailments. Another common problem is the build-up of debris, such as dirt, leaves, and ice, on the rail surface. This can create a slippery surface, reducing the traction between the train wheels and the rails. As a result, trains may experience reduced braking efficiency and increased stopping distances, posing a risk to safety. Furthermore, extreme weather conditions can have a detrimental impact on steel rails. In colder climates, steel rails can contract, leading to rail buckling or track misalignment. On the other hand, in hotter weather, thermal expansion can cause the rails to expand, leading to track buckling. Both issues can result in track deformations and disruption of train services. Additionally, steel rails can be prone to fatigue failure, especially in heavily trafficked areas. The repetitive loading and unloading of trains on the rails can cause stress and microcracks to accumulate over time. If not detected and repaired promptly, this can lead to catastrophic rail failures. Lastly, maintenance challenges can also be a common problem associated with steel rails. Regular inspections and repairs are necessary to address any defects or issues promptly. However, the vast network of rail tracks and the need for continuous operation make it challenging to carry out maintenance without causing disruptions to train services. Overall, the common problems associated with steel rails include wear and tear, debris build-up, extreme weather effects, fatigue failure, and maintenance challenges. Addressing these issues through regular inspection, maintenance, and technological advancements in rail design and materials is crucial to ensure the safe and efficient functioning of railways.

- Q: What is the role of steel rails in railway signaling systems?

- Steel rails play a crucial role in railway signaling systems as they provide the foundation for safe and efficient train operations. The primary function of steel rails in railway signaling is to facilitate the transmission of signaling information between the trackside equipment and the moving trains. Railway signaling systems rely on steel rails to carry electrical signals that communicate vital information such as speed limits, track conditions, and the presence of other trains. These signals are transmitted through various mechanisms, including track circuits, axle counters, and signaling cables, all of which rely on the steel rails as a conductive medium. Track circuits are a fundamental part of railway signaling systems and are used to detect the presence of trains on a particular section of track. They work by creating an electrical circuit between the two rails, and when a train occupies the track, the electrical continuity is disrupted, triggering a signal to the control center. Steel rails provide the necessary conductivity for these track circuits to function effectively. In addition to track circuits, steel rails also play a critical role in axle counting systems, which are used to precisely determine the location and speed of trains. These systems rely on electrical sensors mounted on the rails to detect the axles of passing trains. By accurately counting the axles, the signaling system can calculate the train's position and ensure safe spacing between trains. Furthermore, steel rails provide a physical reference for other signaling equipment, such as signals and train detection devices. Signals, which indicate to train operators when to proceed, are typically mounted alongside or above the tracks, utilizing the rails as a visual reference point. Similarly, train detection devices, such as wheel sensors or treadles, rely on the steel rails to accurately sense the presence and movement of trains. In summary, steel rails are essential components in railway signaling systems. They enable the transmission of vital information between trackside equipment and trains by providing the necessary electrical conductivity. Without steel rails, the signaling system would be unable to accurately detect trains, ensure safe spacing between them, and provide critical information to train operators, ultimately compromising the safety and efficiency of the railway network.

- Q: How are steel rails protected from impact from falling debris?

- Steel rails are typically protected from impact from falling debris through the use of protective barriers or screens, which act as a shield between the rail and the surrounding environment. These barriers are designed to divert or absorb the impact of any falling debris, thus minimizing the potential damage to the steel rails. Additionally, regular inspections and maintenance are carried out to identify and remove any potential hazards or debris that could pose a threat to the rails.

- Q: How do steel rails handle sharp turns?

- Steel rails handle sharp turns by being designed with a combination of factors. The rails are bent in specific angles to accommodate the turn, and the track is banked or superelevated to counteract the centrifugal force. Additionally, the wheels of the train are tapered, allowing them to smoothly transition through the curve without derailing.

- Q: How long do steel rails typically last?

- Steel rails typically have a lifespan of around 30 to 40 years, although this can vary depending on factors such as maintenance, usage, and environmental conditions.

- Q: Can steel rails be customized for specific track requirements?

- Yes, steel rails can be customized for specific track requirements. Steel rails are manufactured in various sizes and specifications to meet the specific needs of different types of tracks. For instance, the length, weight, and cross-sectional shape of the rails can be tailored to meet the specific requirements of a particular track. Additionally, the steel used in the rails can be customized to have specific properties such as strength, durability, and resistance to wear and tear. This customization allows for the construction of tracks that can handle heavy loads, high speeds, or challenging terrain. Furthermore, steel rails can be designed to accommodate different types of rail fastening systems, allowing for flexibility in track construction and maintenance. Overall, the ability to customize steel rails makes them a versatile and adaptable choice for meeting the specific requirements of different tracks.

- Q: What are the common methods used for rail grinding in steel rails?

- The common methods used for rail grinding in steel rails include using a grinding stone or wheel, using a milling machine, and using an automated rail grinding machine.

- Q: What are the noise levels associated with steel rails?

- The noise levels associated with steel rails can vary depending on various factors. Generally, steel rails produce a certain level of noise due to the friction between the train wheels and the rails. However, modern rail systems have implemented various measures to reduce noise levels. One of the main sources of noise is the interaction between the train wheels and the rail tracks. This can result in a continuous humming or rumbling sound as the wheels roll over the rails. The noise levels can be influenced by factors such as train speed, weight, and the condition of the tracks. Higher speeds and heavier trains tend to generate more noise. To mitigate noise, rail operators and engineers have implemented different strategies. One common approach is using resilient rail fastening systems. These systems help absorb vibrations and reduce the transfer of noise to the surrounding environment. Additionally, rail dampers or noise barriers can be installed along tracks in areas particularly affected by noise pollution. Furthermore, advancements in technology have led to the development of quieter rail systems. For instance, the use of composite materials for rail tracks can help reduce noise levels as they exhibit better vibration damping properties compared to traditional steel tracks. Additionally, the design of train wheels and tracks has been improved to minimize noise generation. It is important to note that noise levels associated with steel rails can also be influenced by the surrounding environment. For instance, if the tracks pass through residential areas or areas with reflective surfaces, the noise can be amplified. In such cases, additional noise mitigation measures like sound walls or noise barriers may be implemented. Overall, while steel rails do generate some noise due to the interaction with train wheels, advancements in technology and the implementation of noise reduction measures have significantly reduced noise levels associated with rail systems.

Send your message to us

High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords