Steel Heavy Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Heavy Rail

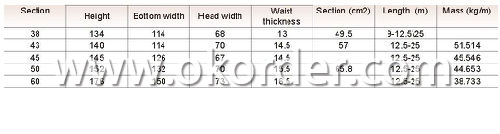

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Steel Heavy Rail

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Tunnel way, curve way, railway, subway, transportation track, express, etc.

Package & Delivery of Steel Heavy Rail

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Heavy Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

Production flow of Steel Heavy Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel rails be used in railway systems with heavy traffic?

- Yes, steel rails can be used in railway systems with heavy traffic. Steel rails are commonly used in railway systems around the world due to their durability, strength, and ability to withstand heavy loads. They are designed to handle heavy traffic and can withstand the weight of trains, even in busy and high-traffic areas. Steel rails are also resistant to wear and tear and have a longer lifespan compared to other materials, making them suitable for railway systems with heavy traffic. Additionally, steel rails are easily maintainable and can be repaired or replaced as needed, ensuring the safe and efficient operation of the railway system.

- Q: How do steel rails handle uneven track settlements?

- Steel rails are designed to handle uneven track settlements by flexing and adjusting to the changes in the track alignment. The flexibility of steel allows it to absorb the impact and distribute the load evenly, minimizing the effects of settlement on the train's stability and smoothness of the ride. Additionally, regular maintenance and monitoring of the tracks help identify and rectify any settlement issues promptly, ensuring safe and efficient rail operations.

- Q: What are the environmental benefits of using steel rails in transportation?

- Using steel rails in transportation offers several environmental benefits. Firstly, steel is a highly durable and long-lasting material, which means that the rails have a longer lifespan compared to other materials like wood or concrete. This reduces the need for frequent replacements, minimizing the environmental impact of extracting and manufacturing new rail materials. Additionally, steel rails provide smoother surfaces for trains to run on, resulting in reduced friction and energy consumption. This leads to lower greenhouse gas emissions and energy usage compared to other modes of transportation, such as road vehicles or airplanes. Furthermore, steel is a highly recyclable material, with a high recycling rate. This means that at the end of their lifespan, steel rails can be recycled instead of ending up in landfills, thereby reducing waste and conserving natural resources. Overall, the use of steel rails in transportation contributes to a more sustainable and environmentally-friendly mode of travel.

- Q: How do steel rails contribute to reducing train accidents?

- There are several ways in which train accidents can be reduced thanks to the presence of steel rails. Firstly, the durability and strength of steel rails enable them to handle heavy train loads and extreme weather conditions, ensuring a stable and secure track structure that minimizes the risk of accidents and derailments. Secondly, the high friction between steel rails and train wheels helps trains maintain traction and grip on the tracks, which is particularly important when traveling at high speeds or needing to brake suddenly. This friction prevents skidding or sliding, thereby reducing the likelihood of accidents. Moreover, steel rails are designed to be resistant to wear and tear, withstanding the continuous weight and pressure of passing trains. This reduces the risk of track damage or failure and prevents incidents such as track buckling or sudden shifts that could lead to accidents. Furthermore, steel rails often come equipped with safety features like signaling systems and automated train control systems. These technologies work in conjunction with the rails to ensure safe distances between trains, adherence to speed limits, and prompt responses to potential hazards. By enhancing communication and control, these safety features contribute to the overall reduction of train accidents. In conclusion, steel rails play a crucial role in reducing train accidents by providing a strong and stable track structure, maintaining traction and grip, resisting wear and tear, and integrating with various safety technologies. The presence of steel rails ensures the safe and efficient movement of trains, contributing to a safer and more reliable railway system.

- Q: Can steel rails be used in areas with extreme weather conditions?

- Yes, steel rails can be used in areas with extreme weather conditions. Steel is known for its durability and ability to withstand harsh environments. It can resist corrosion, which is especially important in areas with high humidity or proximity to saltwater. Additionally, steel rails are capable of withstanding heavy loads and extreme temperature fluctuations, making them suitable for areas with extreme weather conditions such as intense heat or freezing cold. However, proper maintenance and regular inspections are still necessary to ensure the safety and longevity of the steel rails in these areas.

- Q: How do steel rails contribute to train stability during turns?

- Steel rails contribute to train stability during turns in several ways. Firstly, steel rails provide a smooth and stable surface for the train wheels to roll on. The friction between the wheels and the rails helps to maintain the train's stability and prevents it from slipping or derailing during turns. The steel material of the rails also offers high strength and durability, which ensures that they can withstand the weight and forces exerted by the moving train. Secondly, the design of the rails plays a crucial role in maintaining train stability during turns. The rails are typically curved in a specific manner to match the desired turning radius of the train. This curvature, known as the track superelevation or cant, allows the train to negotiate turns more easily. By banking the outer rail slightly higher than the inner rail, the rails help to counteract the centrifugal forces that would otherwise cause the train to lean outwards. This banking effect keeps the train more upright and balanced, enhancing its stability during turns. Furthermore, the track gauge, which is the distance between the two rails, is standardized to ensure the proper alignment and stability of the train. The consistent track gauge allows the train wheels to stay within the rails' confines, preventing excessive lateral movement and reducing the risk of derailment. Overall, steel rails provide a stable and reliable foundation for trains to navigate turns safely. The combination of a smooth rolling surface, track curvature, and consistent track gauge all contribute to maintaining the train's stability during turns, ensuring a smooth and comfortable ride for passengers and safe transportation of goods.

- Q: How do steel rails contribute to train noise reduction?

- Steel rails contribute to train noise reduction in several ways. Firstly, steel is a dense and durable material that helps absorb and dampen the vibrations caused by the movement of trains, thereby reducing the noise generated. Additionally, steel rails are designed with special profiles and shapes that minimize the contact between the wheels and the rails, reducing the friction and resulting noise. Moreover, the smooth surface of steel rails reduces the amount of noise generated by the wheels rolling over them. Overall, the use of steel rails helps to mitigate train noise and create a quieter and more comfortable environment for both passengers and nearby residents.

- Q: What is the process of installing steel rails on bridges?

- Installing steel rails on bridges involves several steps, beginning with a comprehensive survey and inspection of the bridge to assess its condition and determine the necessary type and length of steel rails. This crucial information ensures the rails meet specifications and can withstand anticipated loads and stresses. Following this, existing railings or guardrails are removed, creating a clear space for installing the new steel rails. Depending on their design and attachment method, the removal process may involve cutting, unscrewing, or dismantling the existing railings. Once the area is clear, the steel rails are transported to the bridge site. These rails are typically pre-fabricated sections designed to fit seamlessly together. They are often delivered in easily manageable sections that can be transported to the installation location. The rails are then positioned along the bridge's edge, aligning them with pre-marked locations. Temporary support structures or brackets may be used to hold the rails in place temporarily while the installation process continues, ensuring stability and security. After positioning the rails, they are anchored to the bridge structure using bolts or other fastening mechanisms. These fasteners are inserted through pre-drilled holes in the rails and securely attached to the bridge, creating a durable connection. Once the rails are anchored, they undergo inspection to identify any defects or inconsistencies. Necessary adjustments or repairs are made to meet required standards and regulations. Finally, a thorough inspection of the entire rail system is conducted to ensure proper alignment, secure fastening, and compliance with safety requirements. This inspection may involve specialized tools and equipment to measure alignment, stability, and integrity. In conclusion, installing steel rails on bridges necessitates meticulous planning, precise measurements, and skilled labor to ensure a safe and efficient installation.

- Q: Can steel rails be used in urban tram systems?

- Yes, steel rails can be used in urban tram systems. Steel rails are commonly used in tram systems due to their durability and ability to withstand heavy loads and frequent use. They provide a smooth and stable track for tram operation, ensuring safe and efficient transportation in urban areas.

- Q: What are the common sizes of steel rails used in railway tracks?

- The most common sizes of steel rails used in railway tracks are typically 115-pound, 132-pound, and 155-pound per yard.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Heavy Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords