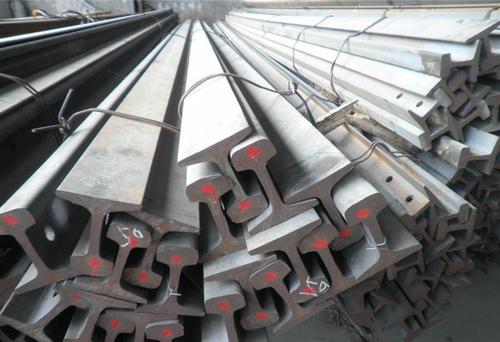

Steel Light Rail with High Quality for Warehouse ,Minas, Structures

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q: How are steel rails protected from excessive noise?

- Steel rails can be protected from excessive noise through various methods. One common approach is the use of rail dampers or rail pads. These are resilient materials placed between the rail and the sleeper, absorbing and reducing vibrations and noise generated by passing trains. Rail dampers can be made of rubber or other elastomeric materials, effectively isolating the rail from the sleeper and reducing noise transmission. Additionally, rail grinding is another technique employed to control noise. It involves removing irregularities and imperfections on the surface of the rail, which can cause increased noise levels. Grinding smoothens the rail, reducing friction and minimizing noise produced during train operations. Moreover, rail fasteners play a crucial role in noise reduction. Modern rail fastening systems, such as resilient fasteners or elastic clips, are designed to absorb and dampen vibrations. These fasteners provide flexibility to the rail, allowing it to absorb energy and reducing noise transmission. Furthermore, the use of noise barriers alongside railway tracks can significantly reduce noise pollution. These barriers, made of materials like concrete or metal, act as sound-absorbing walls, blocking or deflecting noise generated by passing trains. Overall, a combination of rail dampers, rail grinding, resilient fasteners, and noise barriers helps protect steel rails from excessive noise. These measures aim to minimize vibrations, absorb energy, and create barriers to noise transmission, ensuring a quieter and more comfortable environment for both nearby residents and passengers.

- Q: How do steel rails handle the weight distribution of trains?

- Steel rails are designed to handle the weight distribution of trains by providing a strong and durable surface for the wheels to roll on. The rails are made from high-strength steel that can withstand the heavy loads of trains and distribute the weight evenly across the track. Additionally, the rails are laid on a stable foundation to ensure proper weight distribution and prevent any deformities or failures.

- Q: How are steel rails protected from damage caused by hurricanes?

- Steel rails are protected from damage caused by hurricanes through various measures. One common approach is to anchor the rails securely to the ground using concrete ties and fasteners to prevent them from being dislodged or displaced by strong winds. Additionally, rail lines located in hurricane-prone areas may be designed to withstand high wind loads by using stronger materials and construction techniques. Regular maintenance and inspection of the rail infrastructure also contribute to identifying and addressing any potential vulnerabilities before a hurricane strikes.

- Q: Can steel rails be used in urban transit systems?

- Yes, steel rails can be used in urban transit systems. In fact, steel rails have long been the preferred choice for urban transit systems around the world. Steel rails offer several advantages that make them ideal for urban transit systems. Firstly, steel rails provide a smooth and stable track for trains or trams to run on. This smoothness ensures a comfortable ride for passengers, minimizing vibrations and reducing the possibility of accidents or derailments. Steel rails also offer excellent traction, allowing trains to accelerate and decelerate efficiently, which is crucial in urban areas where frequent stops and starts are common. Moreover, steel rails are highly durable and can withstand heavy loads and constant use. This is particularly important in urban transit systems, where trains or trams run frequently and carry large numbers of passengers. Steel rails have a long lifespan and require minimal maintenance, making them a cost-effective choice for urban transit infrastructure. Additionally, steel rails can be easily integrated into existing urban environments. They can be laid on existing roadways or embedded in concrete, minimizing the need for extensive construction work and disruptions to the surrounding areas. Steel rails also have a smaller footprint compared to other track materials, allowing for efficient use of limited urban space. Furthermore, steel rails have proven to be highly reliable and safe in urban transit systems. They have a track record of successful implementation in cities worldwide, ensuring the smooth operation of public transportation networks. Steel rails also contribute to the overall efficiency of urban transit systems by reducing traffic congestion and offering a sustainable transportation option. In conclusion, steel rails are a well-established and suitable choice for urban transit systems. Their smoothness, durability, and reliability make them ideal for providing safe and efficient transportation in densely populated urban areas. The use of steel rails in urban transit systems has been proven effective and advantageous, contributing to the development of sustainable and modern transportation networks.

- Q: How do steel rails handle temperature variations?

- Steel rails handle temperature variations by expanding and contracting. When the temperature rises, the steel rails expand, and when the temperature drops, they contract. This flexibility allows the rails to maintain their structural integrity and prevent any significant damage or warping caused by the changes in temperature.

- Q: Can steel rails be used in automated train control systems?

- Yes, steel rails can be used in automated train control systems. Steel rails have been widely used for many years in railway systems and are compatible with various types of automated train control systems.

- Q: How do steel rails contribute to reducing train derailments?

- Steel rails contribute to reducing train derailments in several ways. Firstly, steel rails are incredibly strong and durable, making them highly resistant to wear and tear. This means that they can withstand the heavy loads and constant friction caused by the movement of trains. By providing a stable and secure track structure, steel rails minimize the chances of derailments caused by track failures. Moreover, steel rails are designed to maintain their shape and alignment under extreme conditions. They can withstand the forces exerted by passing trains and resist bending or warping. This ensures that the track remains in optimal condition, reducing the risk of derailments caused by track misalignment. Furthermore, steel rails are designed to provide excellent traction for train wheels. The surface of the rail is carefully shaped to maximize contact with the train wheels, enhancing their grip and stability. This reduces the likelihood of wheels slipping or sliding on the tracks, which could lead to derailments. In addition, steel rails undergo regular inspections to identify any defects or signs of wear. This proactive maintenance approach allows potential issues to be detected and addressed before they escalate into serious safety concerns. By promptly repairing or replacing damaged sections of the rail, the risk of derailments caused by track defects is significantly reduced. Overall, steel rails play a crucial role in reducing train derailments by providing a strong and durable track structure, maintaining proper alignment, enhancing traction, and enabling proactive maintenance practices. Their reliability and resilience ensure safer and more efficient train operations for both passengers and freight transportation.

- Q: Can steel rails be replaced with other materials?

- Yes, steel rails can be replaced with other materials such as concrete, composite materials, or even new technologies like magnetic levitation systems. However, the replacement material needs to meet specific requirements such as strength, durability, and cost-effectiveness in order to ensure safe and efficient rail transportation.

- Q: How are steel rails affected by changes in train axle loads?

- Steel rails are significantly affected by changes in train axle loads. The axle loads of trains refer to the weight that each axle exerts on the rails. When these loads increase, it puts additional stress on the steel rails, which can lead to various effects. One immediate impact of increased axle loads is increased wear and tear on the rails. The higher the axle loads, the greater the pressure exerted on the rails, causing them to experience more friction and abrasion. Over time, this constant pressure can lead to rail wear, resulting in deformation and even cracks on the rail surface. Moreover, higher axle loads can also cause increased rail deflection. Deflection refers to the bending or flexing of the rail under load. When the axle loads are heavier, the rails are more likely to deflect, which can result in uneven distribution of the load across the rail surface. This uneven distribution can further exacerbate wear and tear and potentially lead to rail deformation or failure. Another significant factor affected by changes in axle loads is fatigue. As the axle loads increase, the cyclic loading on the rails intensifies. This cyclic loading, combined with the constant stress from the weight of the train, can induce fatigue cracks in the steel rails. These cracks can propagate and eventually lead to rail failure if not detected and repaired in a timely manner. Additionally, changes in train axle loads can also impact the overall stability of the track. Higher axle loads increase the risk of track settlement and misalignment. Settlement occurs when the track sinks or shifts due to excessive pressure, potentially causing irregularities in the track. Misalignment can also occur if the rail shifts or twists under heavy axle loads, affecting the geometry of the track and compromising its stability. In conclusion, changes in train axle loads have a significant impact on steel rails. Increased axle loads result in higher wear and tear, increased rail deflection, fatigue cracks, and potential stability issues. Therefore, it is crucial for railway operators and maintenance teams to carefully monitor and manage axle loads to ensure the long-term integrity and safety of the rail infrastructure.

- Q: Can steel rails be used in railway systems with sharp curves?

- Yes, steel rails can be used in railway systems with sharp curves. However, the design and installation of these rails need to consider factors such as the radius of the curve, the speed of the trains, and the weight of the rolling stock. Specialized techniques and technologies, such as bending the rails to match the curve or using flange lubrication, are often employed to ensure safe and efficient operation on curved tracks.

Send your message to us

Steel Light Rail with High Quality for Warehouse ,Minas, Structures

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords