High Quality HR Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

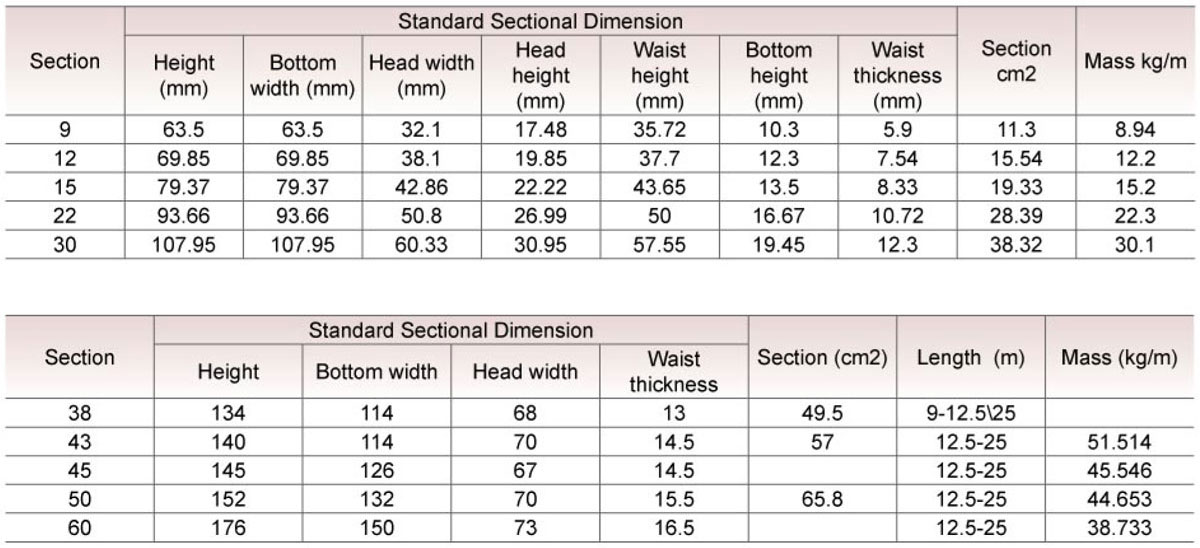

Specifications of High Quality HR Steel Rail:

Available Standard:

Light rail: GB11264-89

Heavy rail: GB2585-81

Available Material Grade:

Light rail:Q235B, 55Q

Heavy rail: 50MN, U71MN

Apllications of Steel Rail

railway

subway

transportation track

express

curve way

tunnel way

Package and Delivery of High Quality HR Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of High Quality HR Steel Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How are steel rails protected from impact damage?

- Steel rails are protected from impact damage through various measures. One common method is the use of resilient materials such as rubber or polyurethane pads placed between the rail and the supporting structure. These pads absorb some of the impact energy and distribute it over a larger area, reducing the stress on the rail. Another method is the application of impact-resistant coatings on the surface of the rail. These coatings are typically made of materials such as epoxy or polyurethane, which provide a protective layer that can absorb and disperse the energy from impacts. In addition, steel rails are often designed to have a certain degree of flexibility to withstand impact forces. This flexibility allows the rail to absorb some of the energy from impacts and distribute it along the length of the rail, reducing the risk of damage. Regular maintenance and inspections are also crucial in protecting steel rails from impact damage. Inspections can identify any potential issues, such as loose or damaged components, and allow for timely repairs or replacements to be made. Overall, a combination of resilient materials, impact-resistant coatings, flexible design, and regular maintenance are employed to protect steel rails from impact damage and ensure their longevity and safety.

- Q: How do steel rails contribute to train speed maintenance?

- Steel rails contribute to train speed maintenance in several ways. Firstly, steel rails provide a smooth and stable surface for the train wheels to roll on. This reduces friction and allows the train to maintain a consistent speed. The low friction also helps in reducing wear and tear on the train wheels and tracks, resulting in less maintenance and longer lifespan. Secondly, steel rails are strong and durable, capable of withstanding heavy loads and constant use. This allows trains to travel at high speeds without the risk of derailment or track damage. The stability and integrity of the steel rails ensure that the train remains on track, maintaining its speed and preventing any accidents. Furthermore, steel rails are designed to be straight and level, which assists in maintaining train speed. The absence of curves or uneven surfaces reduces the need for the train to slow down or adjust its speed, resulting in efficient and consistent travel. In addition, steel rails are carefully engineered to provide proper alignment and gauge. The correct alignment ensures that the train remains on track and minimizes any lateral movements that could affect speed. The gauge, which is the distance between the rails, is also crucial in maintaining train speed. A consistent gauge prevents any lateral movement of the train wheels and ensures a smooth and stable ride. Overall, steel rails play a vital role in maintaining train speed. They provide a smooth surface, strength, stability, and proper alignment, all of which contribute to efficient and safe train travel at high speeds.

- Q: How do steel rails contribute to reducing the risk of rail wear and surface damage?

- Steel rails contribute to reducing the risk of rail wear and surface damage due to their durability and strength. The hard and smooth surface of steel rails helps minimize friction between the rails and train wheels, reducing the wear and tear caused by constant contact. Additionally, steel rails have high resistance to deformation, allowing them to withstand heavy loads and maintain their shape over time. This reduces the likelihood of surface damage, such as cracks or dents, which could compromise the safety and efficiency of the rail system.

- Q: Can steel rails withstand extreme temperatures?

- Steel rails have the ability to endure extreme temperatures. Steel is renowned for its remarkable strength and durability, making it suitable for a wide range of applications, including railway tracks. The design of steel rails takes into consideration extreme temperatures, whether they are high or low. Steel possesses a high melting point, enabling it to withstand high temperatures without distorting or melting. Furthermore, steel exhibits outstanding thermal conductivity, which facilitates rapid heat dissipation and prevents excessive expansion or contraction. This characteristic contributes to the preservation of the structural integrity of steel rails, even in the face of extreme temperature conditions. Moreover, steel is also resistant to cold temperatures, ensuring that it remains resilient and resistant to cracking in freezing conditions. In summary, steel rails are specifically engineered to endure extreme temperatures and provide a reliable and safe transportation system.

- Q: How are steel rails inspected for wear and tear?

- Steel rails are inspected for wear and tear through various methods such as visual inspections, ultrasonic testing, and measurements of rail profiles.

- Q: What are the factors considered in selecting the right steel rail for a railway track?

- There are several factors that are considered when selecting the right steel rail for a railway track. These factors include: 1. Rail weight: The weight of the rail is an important consideration as it affects the overall stability and durability of the railway track. Heavier rail provides better stability and resistance to wear and tear. 2. Rail profile: The shape and dimensions of the rail profile are crucial in ensuring proper alignment and smooth movement of trains. The profile should be designed to withstand the loads and stresses imposed by the rolling stock. 3. Material composition: The composition of the steel used in the rail is essential in determining its strength, ductility, and resistance to fatigue. Different grades of steel with specific properties are selected based on the expected traffic load and environmental conditions. 4. Hardness: The hardness of the rail is crucial in preventing excessive wear and deformation. It should be able to withstand the impact and abrasion caused by the wheels of the trains. 5. Corrosion resistance: Railway tracks are exposed to various environmental conditions, including moisture and chemicals. Therefore, the rail should have good corrosion resistance to prevent rusting and deterioration over time. 6. Manufacturing process: The manufacturing process of the rail is important in ensuring its quality and reliability. Factors such as heat treatment, rolling process, and quality control measures play a significant role in determining the overall performance of the rail. 7. Cost: The cost of the rail is also a factor that needs to be considered. While it is important to select a rail that meets all the necessary requirements, it is also crucial to consider the economic feasibility of the options available. Overall, the selection of the right steel rail for a railway track requires a careful evaluation of these factors to ensure safe and efficient train operations.

- Q: How are steel rails repaired in case of damage?

- Steel rails are repaired in case of damage through a process called rail grinding or rail milling. This involves removing the damaged or worn-out sections of the rail and smoothing the surface to restore its shape and alignment. In some cases, damaged rails may also be replaced entirely to ensure the safety and efficiency of the railway system.

- Q: Are steel rails used in mining cart systems?

- Yes, steel rails are commonly used in mining cart systems. Steel rails are preferred in mining operations due to their durability and strength. They can withstand heavy loads and provide a smooth and stable surface for the mining carts to travel on. Steel rails also offer resistance to wear and are able to withstand harsh environmental conditions, making them suitable for underground mining environments. Additionally, steel rails can be easily maintained and replaced when needed, ensuring the safe and efficient movement of mining carts within the mining system.

- Q: Are steel rails suitable for light rail transit systems?

- Yes, steel rails are suitable for light rail transit systems. Steel rails have been widely used in various types of railway systems for many years, including light rail transit systems. They are known for their durability, strength, and ability to withstand heavy loads and constant use. Steel rails provide a stable and reliable track structure that can handle the weight of light rail trains and ensure a smooth and comfortable ride for passengers. Furthermore, steel rails offer excellent resistance to wear and tear, making them suitable for high-traffic areas and reducing the maintenance requirements of the track. The smooth surface of steel rails also minimizes frictional resistance, allowing trains to operate at higher speeds efficiently. Another advantage of steel rails is their compatibility with various types of rail fastening systems, which facilitate easy installation and maintenance. This flexibility allows for efficient track adjustments and repairs, ensuring the overall safety and reliability of the light rail transit system. Additionally, steel rails can withstand different weather conditions, such as extreme temperatures, heavy rain, and snow, without significant deterioration. This makes them suitable for light rail systems operating in various climates and environments. In conclusion, steel rails are a suitable choice for light rail transit systems due to their durability, strength, resistance to wear and tear, compatibility with rail fastening systems, and ability to withstand different weather conditions. They provide a stable and reliable track structure, ensuring a smooth and comfortable ride for passengers while minimizing maintenance requirements.

- Q: What are the different types of steel rail crossings?

- There are several types of steel rail crossings, including level crossings, grade crossings, pedestrian crossings, and private crossings.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality HR Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords