Heavy Steel with High Quality for Structure Prefabricated House

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Heavy Steel with High Quality for Structure Prefabricated House:

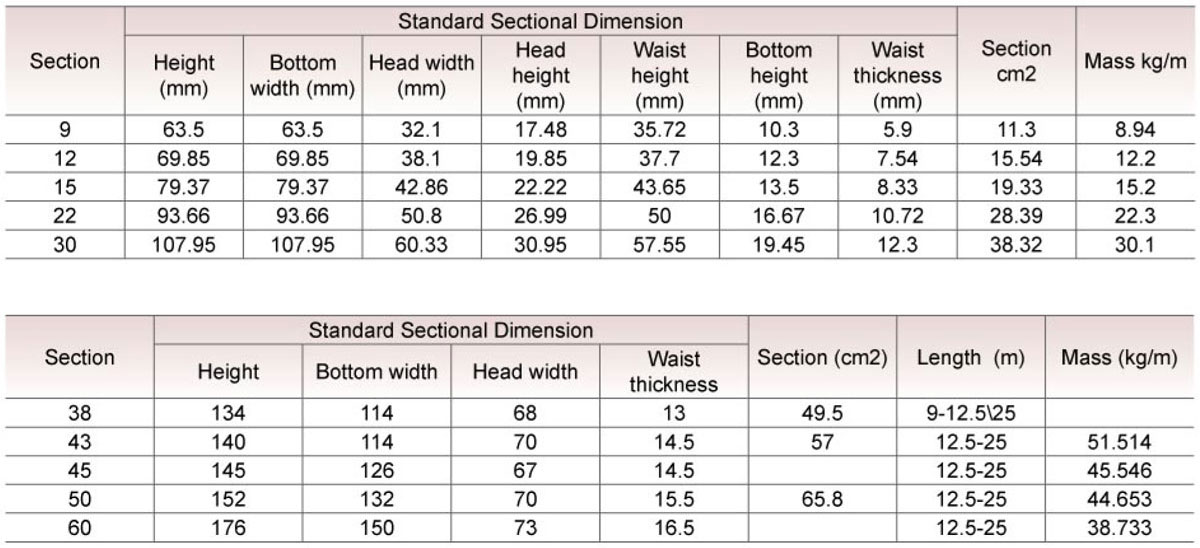

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Heavy Steel with High Quality for Structure Prefabricated House:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Heavy Steel with High Quality for Structure Prefabricated House:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Heavy Steel with High Quality for Structure Prefabricated House:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q: How do steel rails handle changes in train acceleration?

- The purpose of steel rails is to effectively handle variations in train acceleration. Steel possesses desirable properties such as exceptional strength and durability, making it an ideal material for railway tracks. When a train accelerates, there is an increase in the force applied to the rails. However, steel has the capacity to withstand this force without any distortion or breakage. Flexibility is a significant characteristic of steel rails. They are designed to possess a certain level of flexibility, which accommodates alterations in train acceleration. This flexibility aids in evenly distributing the force exerted by the train along the length of the rails, thus preventing localized damage. Furthermore, steel rails are placed on a foundation of ballast, which not only offers additional support but also absorbs the impact caused by the train's acceleration. The ballast acts as a cushion and helps distribute the force exerted by the train over a larger surface area, minimizing the risk of rail damage. Additionally, regular maintenance and inspection of the rails are imperative to ensure their proper functionality in response to changing train accelerations. Prompt identification and resolution of any signs of wear, fatigue, or damage are necessary to uphold the integrity of the rails. In conclusion, steel rails are engineered to effectively handle variations in train acceleration. Their strength, flexibility, and the support provided by the ballast enable them to endure the forces exerted by accelerating trains without any distortion or damage. Regular maintenance and inspection are vital in guaranteeing the safe and efficient operation of steel rails.

- Q: Can steel rails be bent or shaped to fit different track designs?

- Steel rails have the ability to be bent or molded to suit different track designs. Steel possesses exceptional malleability, signifying its capacity to be effortlessly bent, twisted, or molded without fracturing. Manufacturers of rails possess the capability to tailor steel rails, enabling them to conform to specific track designs. This adaptability in shape allows for the creation of curved tracks, switches, and various other track configurations. Specialized equipment, such as hydraulic presses, are employed to exert controlled pressure and mold the steel rails. However, it is crucial to note that the bending process must be executed with caution and precision to ensure the rails retain their structural integrity and can securely bear the weight of trains.

- Q: What is the role of steel rails in signaling and communication?

- Steel rails play a crucial role in signaling and communication by providing a stable and reliable track infrastructure for the smooth transmission of signals and messages between trains and control centers. These rails act as conductors, allowing electrical signals to travel efficiently and accurately, ensuring effective communication for the safe operation and coordination of trains on the railway network.

- Q: How are steel rails inspected for wear and tear?

- Steel rails are inspected for wear and tear through various methods including visual inspections, ultrasonic testing, and measurement of rail profiles. Visual inspections involve trained personnel visually examining the rails for any visible signs of wear, damage, or defects. Ultrasonic testing uses specialized equipment to detect internal defects or cracks in the rails by sending sound waves through them. Lastly, measurement of rail profiles involves taking precise measurements of the rail's shape and dimensions to identify any abnormalities or excessive wear. These inspection techniques help ensure the safety and durability of steel rails in railway systems.

- Q: What is the process of installing steel rails on bridges?

- The process of installing steel rails on bridges typically involves several steps. First, the existing railings or barriers on the bridge are removed, creating a clear space for the steel rails. Then, the bridge surface is prepared by ensuring it is clean and free of any debris or obstructions. Next, the steel rails are carefully positioned and aligned according to the bridge's specifications and requirements. They are then secured in place using bolts, screws, or other suitable fasteners. Finally, a thorough inspection is conducted to ensure the rails are securely attached and meet safety standards before they are opened for use.

- Q: What is the impact of steel rails on train braking distance?

- The impact of steel rails on train braking distance cannot be underestimated. Steel rails serve as a smooth and long-lasting surface for trains to travel on, but they also have a direct effect on the braking capabilities of trains. The high coefficient of friction exhibited by steel rails greatly benefits train wheels by providing exceptional traction. This allows trains to brake efficiently and come to a halt within a reasonable distance. The friction generated between the steel rails and train wheels plays a vital role in decelerating the train and regulating its speed during braking. Moreover, steel rails are meticulously designed to endure the weight and forces exerted by trains. Their robustness ensures that they can withstand the immense pressure exerted on them during braking, providing the train wheels with a reliable surface to grip onto. Consequently, this enhances the overall efficiency of the braking system. Nevertheless, several factors can impact the influence of steel rails on train braking distance. The condition of the steel rails is of utmost importance. If the rails are worn out, damaged, or contaminated with debris, the traction between the wheels and rails diminishes, resulting in longer braking distances. Furthermore, weather conditions also have a significant effect on braking distance on steel rails. Wet or icy rails reduce the friction between the wheels and rails, making it more challenging for trains to brake effectively. To counteract this, special measures, such as the application of sand or anti-icing agents, are implemented during such weather conditions to improve traction and diminish braking distances. In conclusion, the impact of steel rails on train braking distance is undeniable. They offer the necessary traction and durability for trains to brake effectively. However, factors like rail condition and weather conditions can influence braking performance. Thus, regular maintenance and appropriate measures during adverse weather conditions are essential to ensure safe and efficient train braking.

- Q: How do steel rails resist bending and twisting forces?

- Steel rails resist bending and twisting forces due to their inherent strength and stiffness. The high tensile strength of steel allows it to withstand bending forces without permanently deforming, while its rigidity prevents twisting forces from causing significant distortion. Additionally, the shape and design of steel rails, such as their cross-sectional profile and flanges, further enhance their resistance to bending and twisting.

- Q: Can steel rails be used in heritage or tourist railway lines?

- Yes, steel rails can be used in heritage or tourist railway lines. Steel rails are commonly used in modern railways due to their durability, strength, and ability to handle heavy loads. Therefore, they can be equally suitable for heritage or tourist railway lines, ensuring safe and efficient operations for the benefit of visitors and preservation of historical sites.

- Q: What is the average cost of steel rail maintenance?

- The average cost of steel rail maintenance can vary depending on various factors such as the length of the rail, the condition it is in, the specific maintenance activities required, and the location. It is difficult to provide an exact figure without more specific details.

- Q: How are steel rails tested for durability?

- Durability of steel rails is evaluated through a rigorous process that incorporates various techniques and methods. One of these techniques is ultrasonic technology, which involves transmitting ultrasonic waves through the rail to detect any structural defects or abnormalities. Reflection and absorption of these waves enable engineers to identify potential weaknesses or flaws in the rail, which could cause premature failure. Another method employed is fatigue testing, which entails subjecting the steel rail to repeated loading and unloading cycles. This simulation mimics the stress and strain the rail would endure throughout its expected lifespan. By monitoring the rail's response to these cycles, engineers can assess its resistance to fatigue and estimate its durability. Furthermore, regular visual inspections are conducted to visually scrutinize the rail for any visible damage, such as cracks, fractures, or corrosion. Any abnormalities noticed during these inspections are further examined and addressed accordingly, ensuring the rail's durability. Taken together, the evaluation of steel rails' durability encompasses a comprehensive process that combines non-destructive testing techniques like ultrasonic testing and physical testing such as fatigue testing. These tests are vital in ensuring that the steel rails can withstand the demanding conditions of railway operations and maintain their integrity and safety over time.

Send your message to us

Heavy Steel with High Quality for Structure Prefabricated House

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches