Steel Light Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

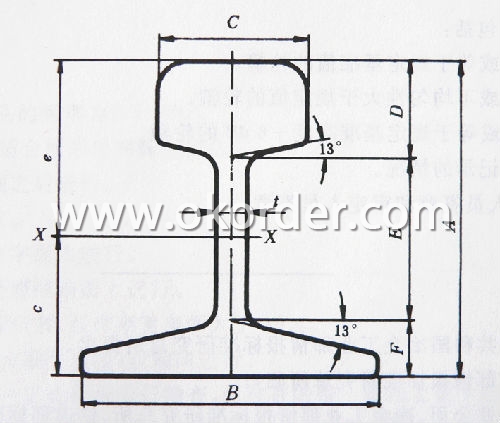

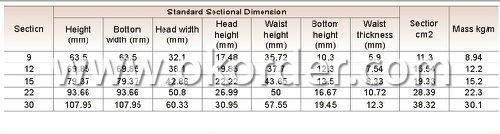

Specifications of Steel Light Rail

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Material: Q235B, 55Q, 900A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Steel Light Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Steel Light Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, material, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Steel Light Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Steel Light Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: How are steel rails protected against chemical exposure?

- Steel rails are typically protected against chemical exposure through the application of protective coatings. These coatings act as a barrier between the rail surface and the chemicals, preventing direct contact and potential corrosion. Additionally, regular maintenance and inspection are carried out to identify and address any potential chemical exposure risks promptly.

- Q: How do steel rails contribute to train speed maintenance?

- Several factors contribute to the maintenance of train speed, and steel rails play a crucial role in this process. Firstly, the smooth and stable surface provided by steel rails allows the train wheels to roll seamlessly, minimizing friction and enabling the train to maintain a consistent speed. This low friction also reduces wear and tear on both the train wheels and tracks, leading to less maintenance and a longer lifespan. Secondly, the strength and durability of steel rails make them capable of withstanding heavy loads and constant use. This ensures that trains can travel at high speeds without the risk of derailment or damage to the tracks. The stability and integrity of the steel rails keep the train on track, ensuring that it maintains its speed and preventing any accidents. Furthermore, the design of steel rails is specifically tailored to assist in the maintenance of train speed. They are engineered to be straight and level, eliminating the need for the train to slow down or adjust its speed due to curves or uneven surfaces. This results in efficient and consistent travel. Additionally, steel rails are carefully engineered to provide proper alignment and gauge. The correct alignment ensures that the train stays on track, minimizing any lateral movements that could affect speed. The gauge, which refers to the distance between the rails, is also crucial in maintaining train speed. A consistent gauge prevents any lateral movement of the train wheels and guarantees a smooth and stable ride. Overall, steel rails are essential in the maintenance of train speed. Their smooth surface, strength, stability, and proper alignment all contribute to efficient and safe travel at high speeds.

- Q: How are steel rails protected from frost and ice?

- Steel rails are protected from frost and ice through various methods such as using anti-icing agents, applying de-icing solutions, and implementing heating systems.

- Q: Can steel rails be used for curved tracks?

- Yes, steel rails can be used for curved tracks. Steel is a commonly used material for railway tracks due to its durability, strength, and resistance to wear and tear. In order to accommodate curved tracks, steel rails can be specially designed and manufactured to have a specific shape that allows for smooth and safe navigation around the curves. These curved steel rails are typically bent or shaped to match the desired curvature of the track. This ensures that trains can travel smoothly and efficiently along the curved sections without causing any derailments or excessive wear on the wheels or tracks. Additionally, the use of steel rails for curved tracks allows for higher speeds and improved stability during turns, making it a preferred choice for railway systems worldwide.

- Q: Can steel rails be used in high-traffic urban areas?

- Yes, steel rails can be used in high-traffic urban areas. Steel rails have been widely used in urban transportation systems, such as subways and light rail networks, due to their durability, strength, and ability to handle heavy loads. They provide a smooth and stable surface for trains to travel on, ensuring safe and efficient movement of passengers and goods in high-traffic urban areas.

- Q: What are the different types of rail fastenings used in high-speed steel rail installation?

- There are several types of rail fastenings used in high-speed steel rail installation, including elastic rail clips, rail anchors, track bolts, and rail pads. Elastic rail clips are the most common type and are used to hold the rail in place and provide flexibility. Rail anchors are used to prevent rail movement and maintain proper alignment. Track bolts are used to secure the rail to the sleepers or ties. Rail pads are used to provide cushioning and reduce vibrations between the rail and the sleepers.

- Q: How much do steel rails weigh?

- The size and type of steel rails can lead to variations in their weight. Typically, a standard steel rail employed in railway tracks has a weight of approximately 50 kilograms (110 pounds) per meter. Nevertheless, this weight may slightly differ based on factors like the rail profile, grade, and manufacturer's specifications. It is crucial to mention that longer rails, as seen in high-speed rail lines, can have a significantly higher weight due to their extended length.

- Q: How do steel rails contribute to railway safety?

- Steel rails contribute to railway safety in several ways. Firstly, steel rails are incredibly strong and durable. They can withstand the weight of heavy trains and provide a stable and reliable track structure. This strength helps to prevent derailments and ensures that trains can travel safely at high speeds without the risk of the rails bending or breaking under the pressure. Secondly, steel rails have a smooth and consistent surface, which allows for smooth and efficient train operation. This reduces the risk of sudden jolts or vibrations that could potentially cause accidents or damage to the train or tracks. The smooth surface also ensures that the wheels of the train can maintain proper contact with the rails, preventing any loss of traction or slipping. Additionally, steel rails are resistant to wear and tear, even under heavy use. They are designed to withstand the constant contact and friction from the train wheels, minimizing the formation of defects or imperfections on the surface. This reduces the risk of any irregularities that could potentially cause accidents or disrupt train operations. Furthermore, steel rails have excellent heat resistance properties. They can withstand the extreme temperatures generated by the friction between the train wheels and the rails. This is particularly important in areas with high-speed trains or heavy traffic, as excessive heat can cause the rails to expand and warp, leading to track deformations or even derailments. The heat resistance of steel rails helps to ensure that the tracks remain stable and safe for train operations. Overall, steel rails play a crucial role in maintaining railway safety. Their strength, durability, smoothness, resistance to wear and tear, and heat resistance properties all contribute to the safe and efficient operation of trains, reducing the risk of accidents and ensuring the smooth flow of rail traffic.

- Q: How do steel rails handle sharp turns?

- Steel rails are designed to handle sharp turns on railway tracks efficiently and safely. The shape and structure of the steel rails allow for smooth navigation through curves. One way in which steel rails handle sharp turns is through the concept of superelevation or cant. Superelevation is the process of tilting the outer rail of a curve slightly higher than the inner rail. This technique helps to counteract the centrifugal force generated during the turn, ensuring that the train stays on the track. It allows for a more comfortable ride for passengers and reduces the risk of derailment. Furthermore, steel rails are made of a durable and flexible material that can withstand the forces exerted during sharp turns. The elasticity of steel allows it to bend and flex under pressure, preventing the rail from breaking or cracking. This flexibility is crucial in maintaining the integrity of the track and ensuring a smooth transition through the curve. In addition to the physical characteristics of steel rails, proper maintenance and inspection play a significant role in handling sharp turns. Regular inspections of the rails, including checking for wear and tear, cracks, and alignment, help to identify any potential issues and prevent accidents. Maintaining the appropriate level of lubrication between the wheels and rails also reduces friction, allowing for smoother movement through curves. Overall, steel rails are specifically designed to handle sharp turns on railway tracks effectively. Through techniques such as superelevation and the inherent flexibility of steel, they ensure a safe and efficient navigation through curves, providing a comfortable and secure ride for passengers.

- Q: What are the potential risks of using steel rails in corrosive environments?

- Using steel rails in corrosive environments can pose several potential risks. Firstly, steel is susceptible to corrosion when exposed to certain elements, such as moisture, saltwater, and chemicals. In corrosive environments, such as coastal regions or areas with high levels of industrial pollution, these elements can accelerate the corrosion process. Corrosion weakens the integrity of the steel rails, making them more prone to damage and failure. Secondly, corrosion can lead to the formation of rust on the steel rails. Rust is a reddish-brown oxide that forms when iron reacts with oxygen and moisture. As rust accumulates on the rails, it can cause surface irregularities, pitting, and roughness. This can result in a decrease in the overall performance of the rails, leading to issues such as increased friction, noise, and vibration during train operations. Furthermore, as corrosion progresses, it can cause the steel rails to thin and weaken, potentially compromising their structural integrity. This can increase the risk of rail buckling or breakage, which can be hazardous for trains and their passengers. In extreme cases, the corrosion may reach a point where it weakens the rails to such an extent that they can no longer support the weight of the trains, leading to derailments and accidents. Another potential risk of using steel rails in corrosive environments is increased maintenance and replacement costs. Corrosion requires regular inspection, cleaning, and protective coating to prevent further damage. These maintenance activities can be time-consuming and expensive. Additionally, the need for frequent replacement of corroded rails can result in higher costs for rail operators and potentially disrupt train schedules. In conclusion, the potential risks of using steel rails in corrosive environments include accelerated corrosion, the formation of rust, decreased rail performance, compromised structural integrity, increased risk of accidents, and higher maintenance and replacement costs. It is crucial for rail operators to implement corrosion prevention and maintenance strategies to mitigate these risks and ensure the safe and efficient operation of rail systems in corrosive environments.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Light Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords