Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

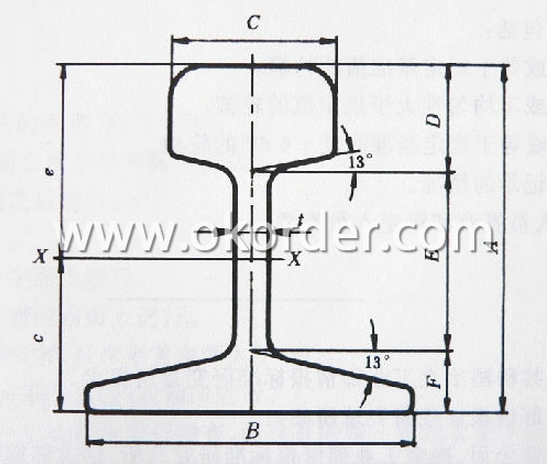

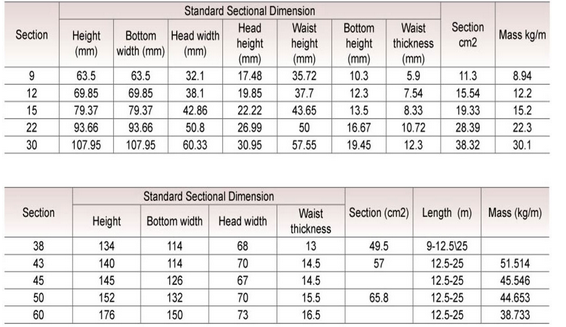

Specifications of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: 55Q

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can fit in the containers of 20inches the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How do steel rails contribute to noise reduction in trains?

- Steel rails contribute to noise reduction in trains due to their smooth surface and structural integrity. The smoothness of steel rail tracks minimizes friction between the train wheels and the tracks, reducing the generation of noise. Additionally, the strength and stability of steel rails help absorb and distribute vibrations caused by the train's movement, further minimizing noise levels.

- Q: Can steel rails be electrified?

- Certainly! Electrifying steel rails is indeed possible. It is a widely implemented practice in modern railway systems. By passing an electric current through the steel rails, trains can be powered without relying on traditional diesel engines. This form of electrification offers several benefits, including enhanced energy efficiency, reduced emissions, and increased speed. Additionally, electric trains operating on steel rails are quieter and require less maintenance compared to their diesel counterparts. To achieve this, steel rails can be electrified through different means, such as overhead wires, third rails, or a combination of both. The train collects the electric current by means of a pantograph or a shoe that makes contact with the electrified rail. In summary, electrifying steel rails has been proven and widely implemented as an effective technique to improve the performance and sustainability of railway systems.

- Q: How do steel rails handle extreme temperatures in desert regions?

- Steel rails are designed to expand and contract with temperature changes, including extreme temperatures in desert regions. They have a high thermal conductivity, allowing them to quickly absorb and dissipate heat. This helps to prevent warping, buckling, or other forms of structural damage that can occur due to thermal expansion. Additionally, rail joints, fasteners, and other components are carefully engineered to accommodate these temperature fluctuations and maintain the integrity of the railway system.

- Q: What is the impact of track irregularities on steel rail performance?

- Track irregularities can have a significant impact on steel rail performance. These irregularities, such as misalignment, wear, and defects, can lead to increased noise, vibration, and rolling resistance, adversely affecting the stability and efficiency of trains. They can also accelerate rail wear and fatigue, resulting in higher maintenance costs and reduced rail lifespan. Additionally, track irregularities can compromise safety by increasing the risk of derailments and accidents. Therefore, it is crucial to regularly monitor and address track irregularities to ensure optimal steel rail performance and ensure the safety and efficiency of railway operations.

- Q: What is the role of steel rails in reducing noise pollution?

- Steel rails play a crucial role in reducing noise pollution in several ways. Firstly, steel rails are specifically designed to provide a smooth surface for train wheels to run on. This smoothness reduces the vibrations and jolts that can generate noise as the train passes over the tracks. By minimizing these vibrations, steel rails help in reducing the overall noise produced by trains. Secondly, steel rails are manufactured to be durable and sturdy, which enables them to withstand heavy loads and maintain their shape over time. This structural integrity contributes to noise reduction by preventing excessive wear and tear on the track. As a result, there is less noise generated from loose or misaligned rails that can lead to rattling or screeching sounds. Furthermore, steel rails are often installed with various noise-dampening measures. These measures can include the use of resilient materials, such as rubber or polyurethane, between the rail and its support system. These materials help to absorb and dampen the vibrations and impacts caused by passing trains, effectively reducing the noise emitted. Additionally, steel rails are designed to have a smooth surface finish, which helps minimize noise caused by friction between the train wheels and the tracks. This reduces the high-pitched squealing or grinding sounds that can be produced when the train is in motion. Overall, steel rails play a significant role in reducing noise pollution associated with train operations. They provide a smooth surface, structural stability, and noise-dampening features, all of which contribute to a quieter and more comfortable environment for both passengers and nearby residents.

- Q: What is the impact of steel rails on train braking distance?

- The impact of steel rails on train braking distance is significant. Steel rails provide a smooth and durable surface for train wheels to grip onto, allowing for effective braking. The high friction between the steel rails and train wheels helps to slow down and stop the train more efficiently. Additionally, steel rails provide stability and reduce the risk of derailment during the braking process. Overall, steel rails play a crucial role in reducing train braking distance and ensuring safe and efficient train operations.

- Q: Are steel rails prone to rail bending?

- Rail bending is a potential issue for steel rails. Although they are designed to be robust and long-lasting, certain circumstances can still cause them to bend. Heavy loads, extreme temperatures, improper installation, and natural wear and tear are all factors that can contribute to rail bending over time. Another aspect to consider is the condition of the ballast, as neglecting its maintenance or compaction can also lead to rail bending. When a rail bends, it can significantly disrupt train operations, increase maintenance expenses, and potentially pose safety risks. To prevent rail bending, it is crucial to conduct regular inspections, ensure proper maintenance, and adhere to design and installation standards.

- Q: What are the considerations for using steel rails in coastal areas prone to saltwater corrosion?

- When considering the use of steel rails in coastal areas prone to saltwater corrosion, several factors need to be taken into account. Firstly, the type of steel used should have a high resistance to corrosion, such as stainless steel or galvanized steel. These materials have a protective layer that prevents saltwater from directly contacting the steel, reducing the risk of corrosion. Additionally, regular maintenance and inspection of the rails is crucial in coastal areas. This includes frequent cleaning to remove salt deposits and applying protective coatings or inhibitors to further shield the steel from corrosion. Proper drainage systems should also be in place to prevent the accumulation of saltwater around the rails. Furthermore, the design of the rails should consider the exposure to saltwater. Elevated tracks or using materials that are less susceptible to corrosion, such as concrete or composite materials, may be more suitable in highly corrosive coastal environments. Overall, the considerations for using steel rails in coastal areas prone to saltwater corrosion involve selecting corrosion-resistant materials, implementing regular maintenance practices, ensuring proper drainage, and considering alternative materials or designs that are less vulnerable to corrosion.

- Q: How are steel rails protected against extreme weather conditions like snow and ice?

- Various methods are employed to safeguard steel rails from harsh weather conditions like snow and ice. One commonly used approach involves applying anti-icing agents or de-icing substances onto the rails. These substances are typically sprayed or spread on the rails before the arrival of winter to prevent the accumulation and adherence of ice and snow to the steel surface. Another method involves the utilization of specialized rail heaters. These heaters are installed along the tracks and are activated during cold weather to warm the rails and prevent ice formation. The heat generated by these heaters melts any snow or ice that may have gathered on the rails, guaranteeing a clear and secure pathway for trains. Moreover, rail operators often rely on snowplows and snow blowers to swiftly remove snow from the tracks. These machines are designed to efficiently eliminate snow and ice, thereby minimizing the risk of derailment or other disruptions caused by accumulation. Furthermore, regular maintenance of the railway infrastructure plays a vital role in protecting steel rails from extreme weather conditions. This includes inspecting and repairing any potential damage to the rails, such as cracks or corrosion, which can be exacerbated by snow and ice. Proper drainage systems are also crucial to prevent water from pooling and freezing on the tracks. To summarize, the protection of steel rails against snow and ice involves the use of anti-icing agents, rail heaters, snowplows, and regular maintenance. These measures ensure the safe and efficient operation of trains even in severe weather conditions.

- Q: How are steel rails protected from wear and tear?

- Steel rails are protected from wear and tear through various measures and maintenance practices. One of the primary methods is the use of rail lubrication systems. These systems apply a thin layer of lubricant to the rail surface, reducing friction between the wheels and the rail. This helps to minimize wear and tear on both the rail and the wheels, resulting in a longer lifespan for the rails. Another important measure is regular inspection and maintenance of the rails. This involves monitoring the condition of the rails for any signs of wear, cracks, or defects. Any damaged or worn-out sections are identified and repaired or replaced promptly to prevent further deterioration and potential accidents. Furthermore, steel rails are often subjected to a process called rail grinding. This involves grinding the surface of the rail to remove any irregularities, such as corrugation or surface cracks. By maintaining a smooth and even surface, rail grinding helps to reduce wear and tear by ensuring a proper contact between the wheels and the rails. Additionally, steel rails are protected from wear and tear through the use of proper ballast and track support. The ballast provides a stable and resilient foundation for the rails, distributing the weight of the trains evenly and reducing the impact on the rails. This helps to prevent excessive wear and tear caused by the constant heavy loads. Overall, a combination of lubrication, regular maintenance, rail grinding, and proper track support are vital in protecting steel rails from wear and tear. These measures ensure a safer and more efficient railway system while extending the lifespan of the rails, reducing the need for frequent replacements, and ultimately minimizing costs.

Send your message to us

Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords