High-performace pipeline ball valve PN 900 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

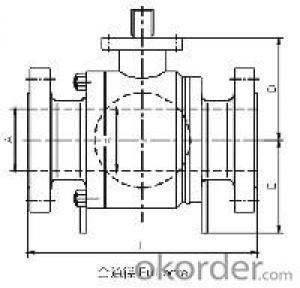

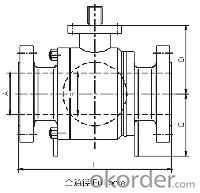

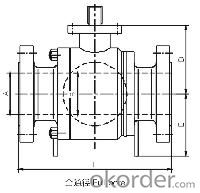

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

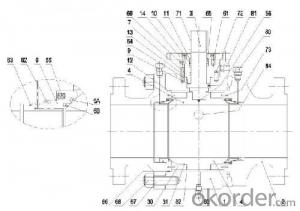

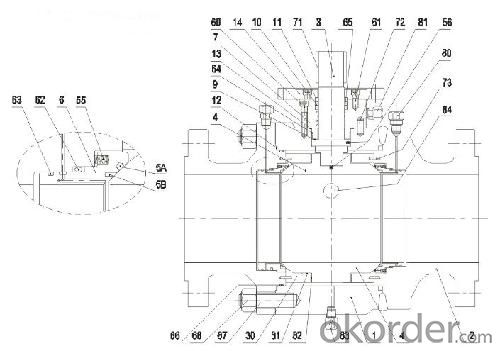

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Can someone explain to me what lead and lag time are? Also, what are the three flow characteristics? Linear, equal percentage but what is the third. If I wanted to have a minimum stop at 25% on a non-linear valve such as a butterfly valve, how would I achieve this. Obviously you cannot just restrict the valve by 25% of its travel as it is not linear

- Hope this helps in some way... To start the 3 main flow characteristics of a control valve are Liner, Equal percentage and Quick opening (or fast opening). If you interested there are also other characteristics. As far as i am aware the lead time is the time in which a signal is sent to the valve and the lag time is the time in which the actuator moves and closes the valve. The pysical movement. As for your final question the only thing i can think of is to alter the actual size of the butterfly valve or put a reducer before it. Sorry if my information was of little use.

- Q: How can I tell if my 2004 Ford Taurus a 12 or 24 valve?

- 12 Ford Taurus

- Q: I was woundering if anyone had a repair manual for this valve on a 2004 Nissan Maxima. I just bought the car and Im getting the P1800 Code. Any help would be appreciated!

- This is NOT a very serious problem. You have an ADJUSTABLE intake runner on this engine. THere is a vacuum operated CONTROL valve very visible with the hood open. It SHIFTS a doorway within the manifold to alter the path of incoming air. THere is a SOLENOID that controls this FLAP IT ALSO is easy to find in plain view if you follow the VACUUM to the valve. Many times ths VACUUM hose itself has collapsed, a VERY cheap repair. WOrst case scenario is to repalce either the SOLENOID or the actual VALVE. It has a rubber diaphragm within it. JUNK yards may have good used ones. You can remove the VACUUM to this valve, and try sucking on it to see if the valve MOVES the flap[ hidden inside the INTAKE MANIFOLD. EZ test, EZ fix. GOOD LUCK!!

- Q: List all the brass instruments with valves? Thanks. I need it for the history exam -.-

- lets see... Trumpet Trombone (Not sure if it would be considered a valve instrument even though it works the same way only you have to do the sliding yourself.) French Horn Tuba and I think there's probably one or two more.

- Q: im having trouble locating the pcv valve on my 1979 oldsmobile. i have a 305 engine. i need to replace it asap, so any help would be appreciated. thanks in advance to all feedback.

- look on the valve covers.it will be at one end with a hose running to the carb.

- Q: behind the valve cover of the #1 and #2 cylinder there are 2 intake and 2 exhaust valves I need know (cylinder #1) which is the intake and which is the exhaust. thank you in advance.

- 1. Intake valves are usually larger than exhaust valves 2. Exhaust valves are on the same side as the exhaust manifold

- Q: I keep the tire pressure in my tires at approx 40 lbs per tire. I have an inexpensive tire gauge that I use to measure the pressure. Recently, one tire seemed low, so I measured the pressure and the batteries were dead in the tire gauge. I replaced them and measured again.It said 20.5! I thought I was going crazy, but then measured all the other tires and they were around 35 to 40. I filled up all the tires to about 40, but when I measured the weird one again, it said only 30!The question is, could there be a problem with the tire valve that is preventing me from getting a good measure of the pressure? I filled up the tire to where it looks really filled up, and I'm afraid to overfill it. I'd like to get it to 40 lbs but I don't know if it's already gt; 40 lbs with a tire valve problem. Or if a tire that's at 20 pounds can look so filled up that you couldn't tell it from a tire that's at 40 pounds?Any info would be appreciated.

- Overinflating your tires beyond what the people who designed, built and exhaustively tested your vehicle recommend because some anonymous nut on a Prius owners forum says to is stupid. Over-inflated tires wear out more quickly which more than cancels out the fraction of a percent of mileage improvement you MIGHT see by doing this. Over-inflated tires also provide less traction thus reducing safety. Over-inflated tires are also more prone to damage from road hazards such as potholes which again could result in having to buy tires prematurely. What you are doing is a false economy. Do what the people who built your car and built your tires (ie: the professionals) recommend and inflate to 35 psi front, 33 psi rear. As for your gauge reading problem, if you are unsure you are getting accurate readings take it to a tire shop for a second opinion by people who do this stuff for a living. They should be able to figure out if you have a problem or not. You can't trust what the tire looks like. A tire can be underinflated by as much as 20 psi and still look OK or grossly overinflated to the point of being dangerous and you wouldn't know by looking at it.

- Q: ive had my yz250f for more than a year and i havent had the valves adjusted......it still starts up in under 5 kicks and rides great.......are there any signs that indicate you need your valves adjusted besides not being able to start it?

- With titanium valves you do not wait until they start ticking. It is a race bike not a Ford Pinto. Do I need to define the term preventative maintenance? They need to be checked a minimum of once a year, if not more. Don't wait for problems, take it in now. As to super cleats answer, I'm sure the factory riders would love to know your secret for making a 4 stroke race bike start on the first kick every time, because they sure haven't figured that one out yet.

- Q: Can someone please explain the difference between a pressure tap valve and a gate valve (if any).

- they have different functions, the pressure bypass valve is normally used in Heating systems, between the Flow and Return circuits, just in case all the radiators are shut and the water has no were to flow, some of the more sophisticated use a pressure differential between one side of the circuit to the other to operate, Also generally set at quite a low pressure. Pressure release valves are used on closed loop central heating systems or other water systems were unwanted pressure can build up, and usually will vent to some sort of outflow, IE over flow pipe or return to a hot water tank and operate at higher pressure and are more likely to be adjustable

- Q: I have a problem with standing water that keeps puddling up and never drains under where my valves are located for my sprinklers. What do I do? Should I just put 3/4 drain rock on top? Please help?

- Sounds to me, like you have one of two things happening. Either you have a leak, which needs to be fixed. Or the valve box is in a low area where the water drains to... Turn on the water and watch the valves.. you might be able to see where the water is coming from. It may be as simple as tightening down the valve screws, or you may need to turn off the water at the main and repair or replace it. If the water is draining there or the leak isn't all that terrible the only way drain rock would help is if you were to dig underneath the valve a little, and to replace what you dig out with rock... Just make sure you can still access everything when you are finished. Good Luck!

Send your message to us

High-performace pipeline ball valve PN 900 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords