High-performace pipeline ball valve 2500 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

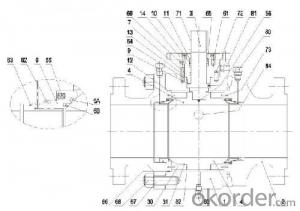

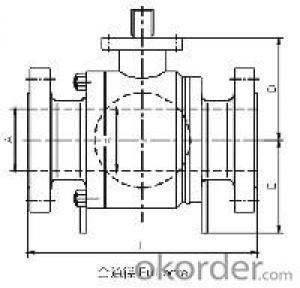

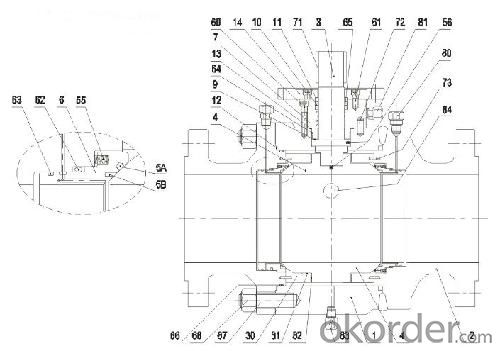

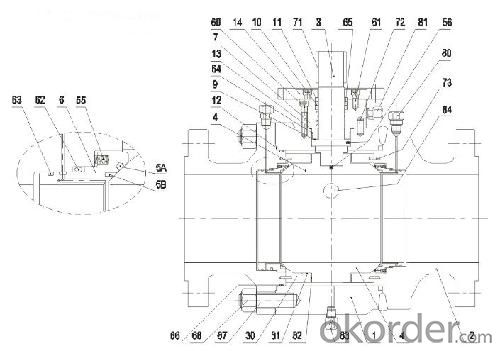

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Full Bore ball vale and Reduce bore ball valve have diferent with each other ,I want to know about them.

- This Site Might Help You. RE: what is diferent between FB ball valve and RB ball valve? Full Bore ball vale and Reduce bore ball valve have diferent with each other ,I want to know about them.

- Q: What is motor operated valve (MOV) please answer me if anybody have experiance in instrumentation filed, please explain overhauling and troble shooting

- Good approach, correct

- Q: I threw a birthday party last night, all went well until 2am when a crazy (drunk!) lady cut all the wires from my heating system (i guess as a prank??? dunno, she is never invited back). I have everything up and running when using one thermostat and connecting the thermostat wires (red directly to tv, Brown directly to W, and white directly to T) and not using the two Honeywell zone valves (model number V8043F. How do I connect those two zone valves to the L8148E aquastat?The valves have on bottom Th-TR, TH and TR and the two top screws are labeled end switch.If you need photos I can take them :)Thanks in advance!

- The zone valves should have 4 wires, 2 yellow and 2 red.The yellow wires are connected to the 24 volt thermostat circuit in a series. The corresponding thermostat turns the motor on, opening the zone valve, closing the end switch and turning on the boiler and the pump. The red wires are the end switch wires. They are just wired together in parallel and anytime at least one opens, it turns the boiler/pump on. Now, you must have one of the Tstat wires going to the boiler, when it calls for heat, it turns the boiler/pump on. You probably have the zone valves locked in the open position. So you will have heat all over the house but just not as much control as you had when you were running individual zones. But, you know what? Your system would be more efficient if you left the zone valves locked open and ran the system from one thermostat! To make it even better, you can run the circulation pump all heating season long ( just wire it direct to 120v) and just use the thermostat to turn the boiler(burner) on when there is a call for heat. If one zone or the other is too hot, try turning a valve down on the return line(if you have valves) to balance the heat. Hope this is not too complicated and hope to help!...................................

- Q: The valve on my mountain bike tire has a leak, so I want to go buy a new valve (and maybe a couple spares)... how much is the average cost?Thanks!

- Pump the tire up to max and then release the air that may clear any dirt out. If it's leaking around the base it needs patched or replaced.

- Q: How much will it cost to fix 5 broken gas valves out of 6 from my truck it's a Chevy s10 99'I live in North Carolina

- The first step is to realize that you need a professional to work on your truck. This is good. By gas valves I assume you mean fuel injectors. But since you did not know that name it would appear as you have not had your truck properly diagnosed. Sounds like you're not getting fuel? spark? air? compression? in five cylinders in your 4.3-W six cylinder. Might want to find out why. Call around and ask whoever answers the phone if you can speak to an ASE Certified tech. If you talk to one then you have probably found a shop to which it would be worth taking the S10.

- Q: It looks like our toilet water shut off valve is leaking. We are trying to turn off the water by turning the lever on the hot water heater, but this only turned off the hot water. So the cold water is still not turned off? We thought the one lever at the hot water heater would turn it all off, but it didn't work. Is there actually a separate water shut off valve for cold water in my house? Help!!

- The water shut off valve is located where the pipe enters the house from the city water main. Maybe on the outside wall of your house near an outside faucet. Or maybe in the ground under a cover plate near an outside faucet, or maybe in the basement near where the pipe comes into the house from outside. There is also ususally a valve out at the water meter. The valve at the hot water heater just shuts of the cold water supply to the hot water heater, so it only effects the hot water.

- Q: When looking at the head on my chevy 350 how do I determine which is the intake valve and which is the exhaust valve?

- the intake valve is usually bigger and on the left. the exhaust valve is usually smaller and on the right. at least it is true in small engines (lawnmowers).

- Q: My car has been sputtering and hesitating when I hit the gas. My friend's boyfriend says it is a bad erg valve does that sound right?

- An EGR valve being open will cause mostly idle problems and light throttle/initial take-off problems...mostly when you have a high manifold vacuum is when you end up with problems because of a sticking EGR valve. Just remove the valve and clean it by soaking it in something like B-12 Chemtool. I can garuntee you that valve is probably disgustingly full of carbon depending on the year.

- Q: I had some great answers to my question yesterday... I have decided to have the valve job done... Since I have decide to go this route... I need some reassurance, the few people I have suggessed this option to have now told me that typically after a valve job other problems will start showing up. They have said that the car isn't worth putting money into and to get ride of it.

- Getting a vlave job done isnt going to hurt your car at all, nor your motor. Make sure you have a reputable machine shop do this (most garages dont have the tools for it). If a 3 angle valve job is done correctly and new valve stem seals, retainers, and spring are all carefully installed to manufacturer spec then there should be no problem at all. Many shops will do a sloppy job grinding the valve face (which is a hard thing to get the knack for) and will install to valves without another thought. When new valves or old valves with resurfaced faces are installed the spring rate of the valve springs needs to be checked to ensure are srpings are the same strength. Also once installed, the height of each installed valve/spring needs to be checked to make sure its in the specified allowance. If valve seats and surfaces are all done correctly along with a profesional installation I wouldn't worry!

- Q: I need to make a ball valve that will open with no manual force but by a motor of some sort to spin it and release water. how do i make a ball valve controlled by preferably a motor or other CHEAP device. I need to do this for less that 20$

- put a slave servo on it,

Send your message to us

High-performace pipeline ball valve 2500 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords