High-performace pipeline ball valve 150 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

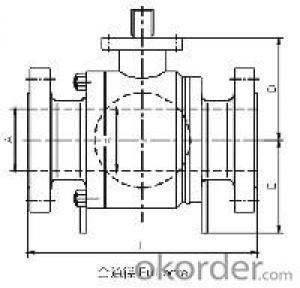

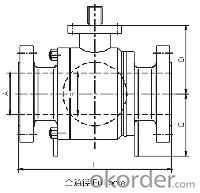

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

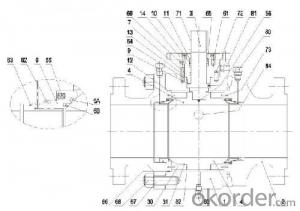

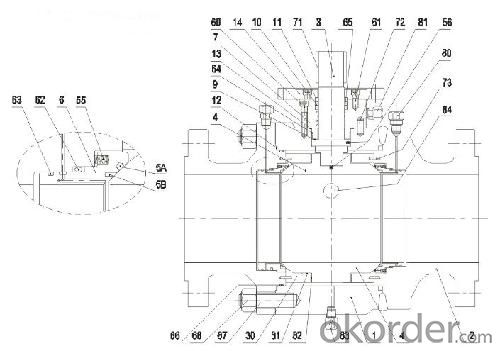

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

- Q: From searching around I feel that I need to replace this on my vehicle. Is the Suction Control Valve different from the Idle Control Valve? Sometimes at a stop light the engine will stall. A couple times it has happened while driving when coasting to a turn or stop.

- hold the computer near the Pathfinder it will suck data directly off the internet (NO WAY) what you need is a complete diagnosis by a experenced Technician or a Nissan Technician. Idle control is on the bottom of the throttle chamber or on the intake manifold. Stalling and Dieing may be caused by a Distributor or air flow meter fuel pump or clogged up fuel filter. Suction control valve in not a part on your year pathfinder good lick

- Q: what does mild sclerosis of aortic valve means? Why does it happens and what is its curethanks

- It means you have some plaque build up in ur aorta. causes are bad diet or gentics. change of diet can help

- Q: I am 16, and i have a leaky heart valve. What makes it worse so i can try to prevent from it getting worse? please help.

- It would be very helpful to know which valve is involved. At your age a bicuspid aortic valve would be the most common congenital heart lesion. Regurgitation tends to increase over time no matter what is done. There is nothing that you will be able to do to prevent this from getting worse if that is the nature of the valvular abnormality. If you provide me with additional information I may be able to offer a more thorough and thoughtful response. I wish you the very best of health and in all things may God bless. JR

- Q: When I flush the toilet it flushes just fine, but it doesn't fill again. You have to close the wall valve and then open it up again to fill the tank. Is this a problem with the valve or the internals of the tank? Thanks

- Check your fill valve (inside the tank) first. If it appears to be working properly, turn the water off outside the house, drain the tank, take the filler tube ( from the valve to the bottom of the tank on the outside) loose at the valve. Remove the valve and inspect for obstructions, such as calcium and or lime deposits. You may need to replace the valve as they will occasionally wash out over time. Reverse this process to put everything back together, and be sure to wrap the male threads on the supply line (pipe sticking out of the wall) with teflon tape.

- Q: I need the valves that I need to press down for the notes on the bass stave. Can someone please write them down for me in a list like this?F = openG = 1 and 3A = 1 and 2 etc.Thanks people.

- Try okorder

- Q: the air valve, how does it propel a paintball in a blowback operated paintball gun how does the size/shape/?? of the valve impact how fast the paintball shoots?

- The majority of blowback paintball guns use a pin valve, which is opened when struck by the hammer. The hammer is held in the back position, with the spring compressed, by a sear. When the trigger is pulled, the hammer is propelled forward by the spring, into the valve. These sorts of markers generally use a “stacked tube” design, in which the valve and hammer is contained in the lower tube, while the bolt, which is connected to the hammer, is in the upper tube. The gas released by the valve is then simultaneously channeled up to the bolt to fire the paintball, and back to push the hammer back into the ****** position (hence the name “blowback”). Poppet valves are usually easy to replace and require little, if any, maintenance. The downside to this design, however, is its high operating pressure, which leads to a larger recoil and arguably less accuracy. The valve is usually designed to accommodate a specific operating pressure. Low pressure valves provide quieter operation and increased gas efficiency when tuned properly. However, excessively low pressure can decrease gas efficiency as dramatically as excessively high pressure. The volume of gas released by the valve directly affects the paintball's velocity. The velocity adjuster alters the pretension on the hammer spring which controls how long the pin valve is held open for, or more correctly how much gas must be released to push it back into the ****** position. EDIT - Sorry but wouldn't even know where to start on designing a valve.

- Q: Holding my right hand up, I am a newbie :) any help is greatly appreciated.a) Comparing the shape of the valve to a golf tee, what is the correct name for the thinnest section of the valve(the part of the golf tee that goes into the ground)b) What is the correct name for the widest section of the valve(the part of the golf tee that the ball is placed on.c) The cylinder that the valve moves up and down in, is it just called the valve cylinder?d) In the valve cylinder?, how does the widest part of the valve keeps things sealed. Does it use a ring(simmilar to pistons) or is it some type of gasket material or is it just zero clearance metal to metal.e) The section of the (valve cylinder?) that is above the seal point or basicaly where the valve spring and the thinnest part of the valve is, does oil flow through here?f) Do (valve cylinders?) generate enough heat to warrant the need for coolant?Newbie City, I know. Any help is GREATLY appreciated.TY

- a) The very end is the tip. Below that are grooves that the keepers lock into. This is actually the thinnest part. Below that is the rest of the stem. The general name for the largest part in total is the valve head. b) Surface sounds right. Hadn't really thought about it before. LOL c) Valve Guide. These can either be just a plain hole in the cylinder head material, or often they have bronze inserts. Plain Guides are often repaired by a process called knurling. d) Valves seal to the head by grinding each at the same angle, (usually 45 degrees) and then they are lapped which is where an abrasive compound is placed in between, and the valve is rotated. This matches the surfaces more closely yet. The parts that seal are called the valve face and the seat which is actually a separate part that is inserted into the head, and can be replaced. e) Oil is supplied to that general area, by either holes in pushrods that lubricate the rocker arm, or in the case of rockers mounted to a shaft, through the shaft. In the first case, oil is supplied by the hydraulic lifters. In the latter, the shaft pedestals are drilled for oil passages. In both cases, oil is present in the area, but is not applied directly to the valves. In fact, the job of the valve stem seal is to keep too much oil from getting in the guides. f) Usually the coolant flowing through the heads is enough to carry away the heat, although some hi-performance engines employ techniques such as hollow exhaust valves filled with sodium. Most normal valves are solid.

- Q: where is the fuel tank selector valve located on the truck?

- Located under the LH center of vehicle, on LH frame rail

- Q: I am having a leaky valve is that normal? the doctor said that it is normal what do i do?

- Like most everything, there are degrees of valvular leakage. A valve can be leaking a lot or a very little amount. Valves are a biologic mechanism and therefore are not precisely manufactured with some areas that don't ideally fit, leading to minor leakage. If you were to take 100 random people off of the street and do an echocardiogram, the vast majority would have one valve or the other that had at least some trivial leakage. Therefore if the majority of people have the same thing and it is not a pathological process, it is essentially normal. Next, certain valves leaking are much more important that other valves. Moderate leakage of the tricuspid valve for instance is not a particularly important finding. But moderate leakage of the aortic valve is a very big deal that requires close medical attention. In sum, valves with trivial leakage do not require serial exams for follow up or any special measures like antibiotics before dental procedures. Since this is such a common finding, it is reasonable to consider this a normal finding. Not knowing precisely what the result was on your echo, I can not specifically advise you. At your next doctor's appointment make a note for yourself to ask him/her for clarification. Good luck.

- Q: I have a Tippmann A5 and I removed the gasline from the tombstone and when i went to put it back in the valve washer is in the way. Please help

- You examine your volecity with a chronograph your interior reach paintball shop would desire to have them, you additionally can purchase one on Ebay i would not propose a handheld get one you are able to set up on a tripod like a digicam. a diffusion chamber we could the liquid Co2 increase into gas to keep away from the liquid Co2 to circulate into your marker The low stress kit is designed for working Compressed air no longer co2 it enables with decreasing the the working stress of your marker so which you get greater cosistant photos use much less gas

Send your message to us

High-performace pipeline ball valve 150 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords