High-performace pipeline ball valve PN 600 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

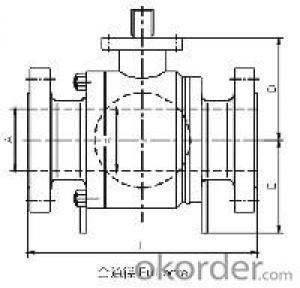

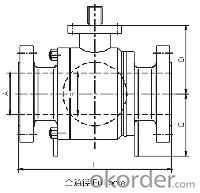

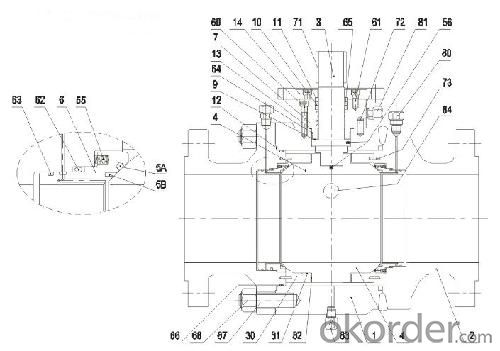

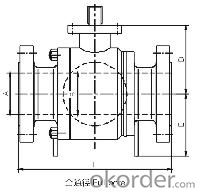

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

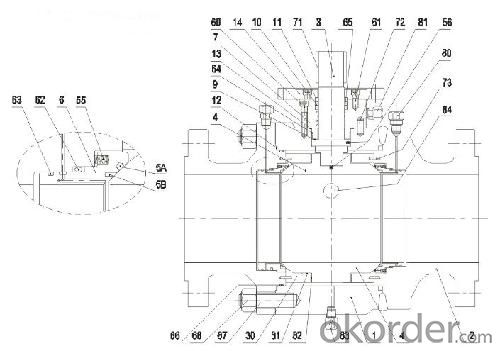

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I believe my EGR valve is bad. I am having symptoms of a bad one. If I unplugged it and took my car for a drive would the symptoms improve, if in fact it is a bad EGR valve?

- Most it could go either way depending upon the failure mode (stuck open, stuck closed, leaking, etc). I use a hand operated vacuum pump ($20 at most car parts stores). Connect it and see if you can draw a vacuum and if it holds the vacuum That will tell you if the diaphragm is okay. Also check the valve seat itself to see if it seals properly when closed. EGR valves run about $20-$50 depending upon car. Also, just because the EGR valve isn't working does not mean the valve is bad. You could have a faulty or disconnected vacuum line preventing the valve from operating. That was my problem in stead of replacing the EGR valve and the catalytic converter as recommended by an Emission Repair Station located just outside the state emission test station. The repair station is no longer in business.

- Q: can anyone tell me the difference between Pressure Safety valveTemperature Safety ValvePressure Relief Valveused in a process industry

- Pressure Safety valve and Pressure Relief Valve are essentially the same. When fitted on a pressure vessel they limit the internal pressure to specified limits. When the pressure exceeds a set value they open to release the pressure. Some types will maintain the pressure (Like the pressure regulator on a pressure cooker) others will release all the pressure. Temperature Safety Valves are used in boiler type of vessels containing a boiling liquid, which generates the pressure (Again like a pressure cooker). Usually there is an equilibrium between the pressure and the temperature. In such applications a temperature responsive valve is used to control the inside pressure to safe levels. If based on thermal expansion, they can regulate. Otherwise a fusible alloy just melts and releases all pressure in one go.

- Q: My 10 year old boy was diagnosed with a leaking heart valve yesterday.The Doctor is trying to get him in to see a specialist asap.She didn't seem that concerned with it,but I don't know if she was just trying to keep us calm about it.How serious is this,and is surgery the only way to fix it,or do they have meds for this condition.

- You have not stated which valve is leaking. Most probably Valve complaints are due to mitral valve and/or aortic valve. Heart valves are damaged due to rheumatic fever. Mitral stenosis (MS) is narrowing of the mitral orifice impeding blood flow from the left atrium to the left ventricle. The (almost) invariable cause is rheumatic fever. Common complications are pulmonary hypertension, atrial fibrillation, and thromboembolism. Symptoms are those of heart failure; signs include an opening snap and a diastolic murmur. Diagnosis is by physical examination and echocardiography. Prognosis is good. Medical treatment includes diuretics, β-blockers or rate-limiting Ca channel blockers, and anticoagulants; effective treatment for more severe disease consists of balloon valvotomy, surgical commissurotomy, or valve replacement. Mitral regurgitation (MR) is incompetency of the mitral valve causing flow from the left ventricle (LV) into the left atrium during systole. Common causes include mitral valve prolapse, ischemic papillary muscle dysfunction, rheumatic fever, and annular dilation secondary to LV systolic dysfunction and dilation. Complications include progressive heart failure, arrhythmias, and endocarditis. Symptoms and signs include palpitations, dyspnea, and a holosystolic apical murmur. Diagnosis is by physical examination and echocardiography. Prognosis depends on LV function and severity and duration of MR. Patients with mild, asymptomatic MR may be monitored, but progressive or symptomatic MR requires mitral valve repair or replacement.

- Q: So i was looking for car parts and i was using my favorite website, and i was looking at turbos which are wicked costly. But i saw some blow off valves which i have heard about before. But i was wondering if you need a turbo in order to have a blow off valve installed into your car. And if you don't my next question would be is it hard to put one in and how?? Thank you for your time..

- A blowoff valve goes onto your intake or the piping from your turbocharger to make sure that you dont run to much pressure they are adjustable to whatever pressure you desire. Usually people running a positive displacement blower or a turbochargers run them. That being said I'm sure that you could put one on your car but without a power adder it would never blow off. Except in the case of a intake manifold overpressure such as a backfire.

- Q: ok so the water main that comes into the basement the valve handle snapped off so how do i shut the water off so i can replace that valve? I called the water company and they said they cant shut off the supply to the house because it is private property and we have to call a plumber if so how can they shut the water off and on if we dont pay the bill?

- Near the curb on your street you will see the Concrete box with the metal lid. Take the whole lid off. The valve should be inside. You need a tool for this or you can do what I do. Put a Big crescent wrench on the valve. Then take larger Chanel locks and grab the crescent wrench and turn a full 180 degrees. Check your sinks for the results.

- Q: When looking at the head on my chevy 350 how do I determine which is the intake valve and which is the exhaust valve?

- the intake valve is usually bigger and on the left. the exhaust valve is usually smaller and on the right. at least it is true in small engines (lawnmowers).

- Q: and that i need a valve job. what is a valve job, and is it expensive? i have a stock 1.6 SI motor in it, but i want to make my car better and faster, would it be cheaper to buy a new engine? some of the people who want to buy my car say that they would put a B16 vtec in it. what is that, and how much better is it than my engine?

- A valve job involves removing the head from the engine, disassembling the head regrinding the valves seats and installing new valve seals guides. new engine vs. valve job? Depends on how many miles are on the original engine. It's seldom a good idea to do only a valve job on a hi mileage engine. Valve job would be cheaper at first, unless you plan on keeping the car for a long time, then a new engine would be a good choice. Maybe the guy was just setting you up to ask for a lower price?

- Q: my friend needs a flap valve replacement. does anyone no how serious this is, i dnt wanna lose my best friend?!!!

- pricey Vongirl, Congratulations on the lengthy lasting heart valve. frequently mechanical valves do not very last somewhat that lengthy. Mechanical, bovine, porcine and donor valves all positioned on out. It in basic terms relies upon on the timing. i'd say two decades with an same valve is somewhat magnificent. i wish, once you get your replace it lasts two decades besides!!!

- Q: need a different pump for? Is this some improvement on the old valve?

- There are schrader valves which are bigger diameter and are used also for automotive tires. They have a spring-loaded center pin that gets pushed down and opened when a inflating head is used. The spring is what keeps the air in the tube. The presta valve is the skinnier one. It does not rely on a spring to keep the valve close. The air pressure inside the tube keeps the valve closed. Generally, less expensive bikes use schraders while better bikes use prestas. All decent pumps have pump heads that accomodate both types. Either it is done by manually reversing the inside of the head assembly to change between presta and schrader or the head automatically adjusts or you use the appropriate one when the head has holes for both.

- Q: One day i was cleaning my trumpet's third valve. when i tried pressing the key it was goig inok but near the end it gets stuck and gets unstuck like a second later.how can i fix this problem with out spending too much money?

- clean the valve and the tube the valve fits in. You will need to take the bottom cap off and with valve oil on a soft cloth (t shirt) wipe out the inside completely wipe down the valve with the cloth also. Clean the spring that pushes the valve back up. Use a tiny bit of vaseline and a liberal amount of valve oil on the valve. Replace everything. If this doesn't do it, take it to the repair shop.

Send your message to us

High-performace pipeline ball valve PN 600 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords