High-performace pipeline ball valve DN 2 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

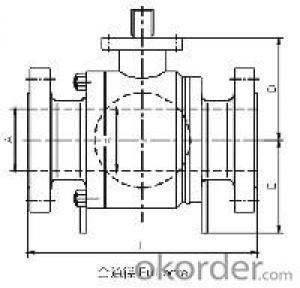

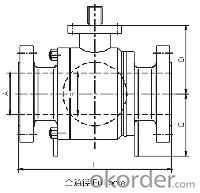

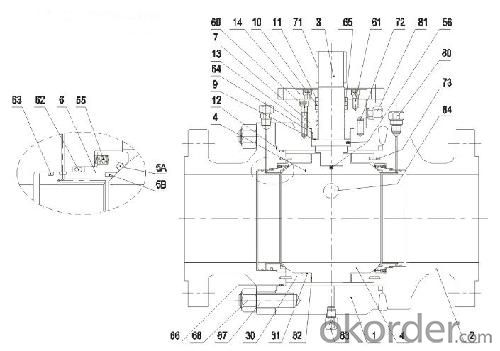

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

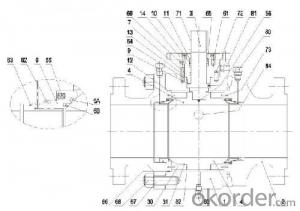

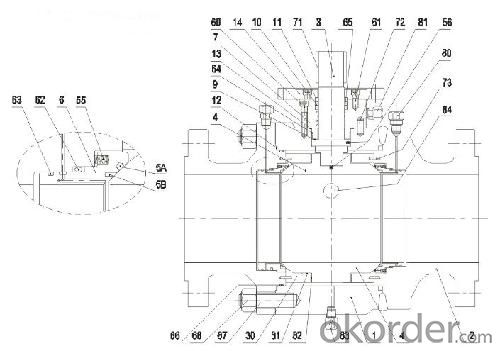

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: My sprinkler valve I just put in leaks from the top knobs you turn to allow water to pass through to the 3 main pvc pipes. I turn the water on on the main water line, open the little black twisty knobs to allow the water to pass through to the irrigation lines, but water leaks out through all 3 black twisty knobs. What do I need to do?!?!?!

- You are turning on electric valves, manually, with the bleeder valve (little black twisty thing). It is normal for this to happen. This valve can turn on and off a zone, but it also releases air from within the lines causing water to spit out with it. After the air is out, you can twist it down enough to stop the leak and still have that zone remain on.

- Q: I am going to replace the EGR valve on my 99 Pontiac GP with the 3.8. It needs replacing(has already been cleaned twice) and keeps popping the code for it. Anyways..my question is: after its replaced what do I need to do to reset the codes or computer? Someone told me to unhook the battery for a hour and that will do it???? Is this true? Any help out there?? THANKS!!!!!!!!!!!!!!!!!!!!

- All you need to do is unhook the positive cable and the negative cable from the battery and touch them together for 10 seconds this will reset the computer. (cant get shocked). thanks please add me to your contacts so i know if it helped.

- Q: We just got a new washer and cannot remove the old hoses from the pipes with the shut off valves on them. I don't want to bend or break anything. any suggestions?

- I understand your problem. Excessive fource could snap off the faucet. Use your old hoses for now if they look like there in good shape. Use a good penetrating oil every day for a week and try again. Just a couple drops each time will do. WD40 is not a penetrating oil.

- Q: school starts tomorrow that means having band and i havent played it in 2 months (summer vacation) and i oiled the valves and the 1 and 2 valves are stuck the 1st valve comes up slowly when i push it down but on the 2nd valve it stays down how do i undo this???? thank you

- Unscrew your valve, remove the bottom valve cap, and carefully push out the valve with a drumstick or something. Clean the valve off with a cotton swab and some vinegar, rinse it off gently with lukewarm water, oil 'er up, and put her back in. If you've messed your instrument up to the point where your valve caps are all stuck from lack of cleaning, you're going to have to take it to a professional. Don't force them with a tool or anything or you'll strip them. Haha, good luck. Matt

- Q: I just got my water pump replaced on my Peerless boiler. Now my backflow valve is always dripping. I am unsure if I should cap it off or if the dripping will stop over time. It seems that there is some pressure comming from the vent. What should I do??

- The seal may be worn. Call back the company that installed the pump...

- Q: is a 4 cylinder 16 valve.... 5 stars for the best answer....

- mazda dealer or find one in the junk yard.

- Q: my friend needs a flap valve replacement. does anyone no how serious this is, i dnt wanna lose my best friend?!!!

- Its heart surgery, which is riskier than many other surgeries, but valve replacement is routine procedure. There's a variety of different procedures that are used and several different types of replacement valves. Some valves can be repaired and some need to be replaced. Repairs usually give a person a normal or nearly normal valve that will last forever. Valve replacements don't work quite as wells as repairs and they usually need to be replaced in a decade or so. Most people can have the valved replaced by threading a scope through the arteries or using tiny incisions, but some people require open heart surgery. My friend had one of his valves replaced with a valve made from a pig heart and he was only in the hospital one night, and back to work a week later.

- Q: What would be the effect on valve opening if the clearance was set too large or too small, please help

- Too Much Valve Clearance

- Q: how do you adjust the hyd. valves when motor is running?? thanks, jerry swain

- The adjustment is a mess if you don't have the clips that go on the rocker arms to stop the oil from splattering all over the place. If you want to try it without the clips, then you simply use a socket on each rocker lock nut and back the nut off until the valve starts to click, then tighten the nut back down until the rocker stops clicking then turn it an additional 1/2 turn. Its much easier to adjust the valves to zero lash without the engine running. to do that, follow the adjustment procedure in any Chilton or Haynes manual to put the engine at either TDC or BDC and adjust the valves in the sequence that is specified. Zero lash essentially means you can't move the pushrod up or down when the rocker is tightend down to the point where all freeplay is removed. I'd recommend duing the zero lash adjustment rather than adjusting them with the engine running hope that helps

- Q: My car (RWD) has vacuum leak and has the code PO171/PO174. I find some engine oil at the bolt well of the valve cover on the bank 2 side. Can the vacuum leak come from the valve cover? What is the main function of the valve cover? Thanks.

- get a new p.c.v. vale . and in air cleaner is a a small filter that hose clips to . .most imporent is pcv vale is working and this will stop

Send your message to us

High-performace pipeline ball valve DN 2 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords