High-end Steel Structure Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

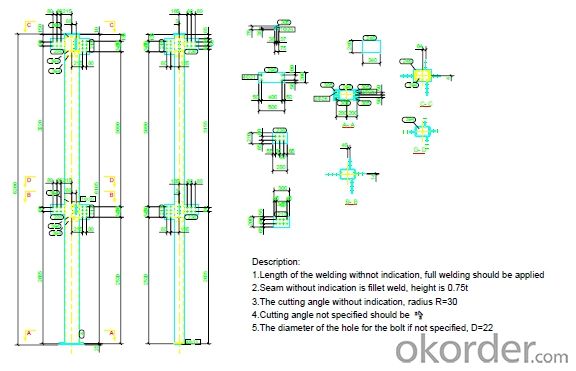

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

The new railway section of bullet train is the inspection and repair base for north China and

the inspection and repair center for the north section of Beijing to Shanghai high-speed

railway. The total area is 183,330 square meters. The steel structure adopt arch steel truss

with maximum span 36 meters.

- Q: How are steel structures designed to provide maximum durability and strength?

- Steel structures are designed to provide maximum durability and strength through several key factors. Firstly, the design takes into account the load-bearing capacity of the structure, ensuring that it can withstand the forces it will be subjected to. Secondly, engineers carefully calculate the optimal size and shape of steel members to distribute the loads evenly and prevent any weak points. Additionally, advanced steel fabrication techniques, such as welding and bolting, are employed to create strong connections between the structural elements. Finally, proper maintenance and corrosion protection measures are implemented to enhance the longevity and durability of steel structures.

- Q: What are the design considerations for steel mixed-use buildings?

- Some key design considerations for steel mixed-use buildings include structural integrity, fire resistance, acoustic performance, building aesthetics, efficient space planning, sustainability, and flexibility for future modifications or expansions.

- Q: How are steel structures different from concrete structures?

- Steel structures and concrete structures differ in several ways. Firstly, steel structures are typically lighter and more flexible than concrete structures, making them easier to transport and assemble. Concrete structures, on the other hand, are heavier and require more time and effort to construct. Additionally, steel structures can be fabricated off-site and then assembled on-site, whereas concrete structures are usually built on-site. Steel structures also have a higher strength-to-weight ratio, making them more suitable for high-rise buildings and structures that require large open spaces. Concrete structures, on the other hand, offer better fire resistance and durability. Overall, the choice between steel and concrete structures depends on factors such as cost, design requirements, and intended use of the structure.

- Q: What is the role of steel in food processing facilities?

- Steel plays a crucial role in food processing facilities as it is used extensively in the construction of equipment, machinery, and infrastructure due to its durability, corrosion resistance, and hygienic properties. From processing equipment like mixers, conveyors, and storage tanks, to work surfaces, walls, and flooring, steel provides a safe and clean environment for food production. It helps maintain cleanliness standards, prevents contamination, and ensures the efficient and safe processing, handling, and storage of food products.

- Q: How do steel structures perform in extreme weather conditions?

- Steel structures generally perform well in extreme weather conditions. Due to their high strength and durability, steel structures can withstand heavy winds, snow loads, and even earthquakes. Additionally, steel does not warp, crack, or rot like other materials, making it resistant to moisture and corrosion. However, it is important to note that proper design and construction techniques must be applied to ensure the structural integrity and safety of steel buildings in extreme weather events.

- Q: What are the considerations for steel structure design in arctic climates?

- When designing steel structures for arctic climates, several key considerations must be taken into account. Firstly, the extreme cold temperatures can cause steel to become brittle, leading to reduced strength and potential structural failures. Therefore, the selection of appropriate steel grades with high ductility and toughness is crucial to ensure structural integrity. Secondly, the design should account for the significant temperature variations and thermal expansion and contraction of steel. This can be achieved by incorporating expansion joints and flexible connections to accommodate the steel's movement without inducing stress concentrations. Additionally, the design should address the effects of snow accumulation and ice formation. Adequate snow load calculations and proper detailing to prevent snow drifts and ice buildup are essential to maintain structural stability and prevent excessive loading. Moreover, the corrosive nature of Arctic environments, due to exposure to saltwater or chemicals used for de-icing, calls for robust corrosion protection measures. This may include selecting corrosion-resistant steel coatings or employing effective maintenance practices to mitigate the risk of corrosion and structural deterioration. Lastly, considerations for transportation and logistics in remote Arctic locations should also be factored into the design. The challenges of accessing construction sites and transporting heavy steel components in these harsh environments must be carefully planned and accounted for. In conclusion, the considerations for steel structure design in arctic climates encompass selecting appropriate steel grades, accommodating thermal expansion, addressing snow and ice loads, implementing corrosion protection measures, and accounting for logistical challenges.

- Q: What is the process of erecting a steel structure?

- The process of erecting a steel structure typically involves several steps. First, the site is prepared, which includes clearing the land, leveling the ground, and ensuring proper drainage. Next, the foundation is constructed, which could be a concrete slab or footings, depending on the design. Once the foundation is ready, steel columns and beams are assembled and connected using welding or bolting techniques. After the framework is in place, secondary steel components such as braces, purlins, and girts are added to provide stability and support. Finally, the structure is enclosed with metal roof and wall panels, and finishing touches such as insulation, electrical and plumbing systems are installed. Throughout the process, safety measures and engineering standards are followed to ensure a sturdy and durable steel structure.

- Q: How do steel structures perform in terms of resistance to natural disasters such as hurricanes and tornadoes?

- Steel structures generally perform well in terms of resistance to natural disasters such as hurricanes and tornadoes. Due to their strength and durability, steel buildings have the ability to withstand high winds and intense forces. The flexibility and ductility of steel allow it to bend and absorb energy during extreme weather events, reducing the risk of collapse. In addition, steel structures can be designed and engineered to meet specific wind and seismic codes, ensuring their resilience against these natural disasters. However, it is important to note that the overall performance of steel structures also depends on proper design, construction, and maintenance practices.

- Q: What are the considerations for designing steel storage tanks?

- When designing steel storage tanks, several important considerations need to be taken into account. These include the intended use and contents of the tank, such as whether it will store liquids or gases, as well as the required capacity and dimensions. Additionally, factors like the environmental conditions, such as seismic activity or wind loads, must be considered to ensure the tank's structural integrity. Other considerations include the selection of suitable materials, corrosion protection measures, and compliance with relevant industry standards and regulations.

- Q: How do steel structures perform in terms of electromagnetic shielding or interference?

- Steel structures perform very well in terms of electromagnetic shielding or interference. Due to their high electrical conductivity, steel structures can effectively block and divert electromagnetic waves, minimizing interference from external sources and protecting sensitive equipment or electronic devices within the structure.

Send your message to us

High-end Steel Structure Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords