High-end Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

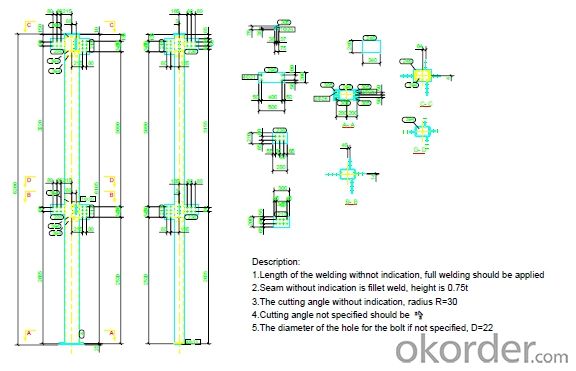

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

The new railway section of bullet train is the inspection and repair base for north China and

the inspection and repair center for the north section of Beijing to Shanghai high-speed

railway. The total area is 183,330 square meters. The steel structure adopt arch steel truss

with maximum span 36 meters.

- Q: Can steel structures be designed for easy dismantling and reuse?

- Yes, steel structures can indeed be designed for easy dismantling and reuse. One of the key advantages of steel structures is their flexibility and adaptability, allowing for easy disassembly and reassembly. To achieve easy dismantling and reuse, several design considerations need to be taken into account. Firstly, the structure should be designed in a modular manner, with individual components that can be easily disconnected and removed. This can be achieved by using bolted connections instead of welded joints, which can be easily undone. Additionally, the use of standardized components and dimensions can facilitate dismantling and reuse. By designing the structure with standard sizes and shapes, it becomes easier to remove and replace components, as well as find suitable replacement parts. Furthermore, careful planning and labeling of the structure during the construction phase can greatly facilitate dismantling and reuse. By clearly marking each component and documenting its location, the process of disassembling and reassembling the structure becomes more efficient and less prone to errors. Lastly, the choice of materials and finishes can also impact the ease of dismantling and reuse. For example, using coatings or finishes that can be easily removed or replaced can simplify the process of refurbishing or repurposing the structure. Overall, with proper design considerations and planning, steel structures can be designed to be easily dismantled and reused, providing a sustainable and cost-effective solution for construction projects.

- Q: What are the design considerations for steel commercial buildings?

- When designing steel commercial buildings, it is important to take into account various factors such as structural integrity, aesthetics, functionality, sustainability, and cost-effectiveness. Structural integrity is a crucial aspect to consider when designing steel commercial buildings. These structures must be able to withstand different types of loads, including wind, snow, and seismic forces. Steel structures are known for their strength and durability, making them an ideal choice for commercial buildings that require large open spaces and flexible layouts. Aesthetics also play a significant role in commercial buildings, as they often serve as a representation of the business or brand. Steel structures offer versatility in design, allowing for unique architectural features and creative façade options. The use of steel also allows for the incorporation of large windows and open spaces, creating an inviting and visually appealing environment. Functionality is another important consideration in commercial building design. The layout and design should optimize the functionality of the space and meet the specific needs of the business. Steel structures provide column-free spaces, offering flexibility for interior layouts and efficient utilization of floor space. This flexibility also allows for future expansions or modifications to the building. Sustainability is an increasingly important aspect in building design. Steel is a highly sustainable material, as it can be 100% recycled and reused without losing its properties. Moreover, steel structures can incorporate energy-efficient features, such as insulation, solar panels, and efficient HVAC systems, reducing the environmental impact of the building. Cost-effectiveness is a significant consideration for commercial buildings. Steel structures are usually quicker to construct compared to traditional building materials, resulting in reduced labor costs and minimal disruption to business operations. The durability and low maintenance requirements of steel buildings also contribute to long-term cost savings. In conclusion, the design considerations for steel commercial buildings encompass structural integrity, aesthetics, functionality, sustainability, and cost-effectiveness. By carefully taking these factors into account, architects and engineers can create efficient, visually appealing, and sustainable commercial buildings that meet the specific needs of businesses.

- Q: How are steel structures designed to accommodate natural lighting and ventilation?

- Steel structures can be designed to accommodate natural lighting and ventilation in several ways. One common approach is to incorporate large windows or glass panels into the design of the structure. These windows or panels can be strategically placed to allow natural light to enter the building and illuminate the interior spaces. Additionally, these openings can be designed to facilitate cross ventilation, allowing fresh air to flow through the building and improve air quality. Another method is to incorporate skylights or roof vents into the steel structure. Skylights are transparent or translucent panels that are installed on the roof, allowing natural light to enter the building from above. This not only helps to reduce the need for artificial lighting during the day but also creates a visually appealing and vibrant atmosphere. Roof vents, on the other hand, can be designed to open and close, allowing hot air to escape and fresh air to enter the building, promoting natural ventilation. Steel structures can also be designed with open floor plans or high ceilings to maximize the distribution of natural light throughout the building. By eliminating unnecessary partitions or walls, light can easily penetrate into different areas, reducing the need for artificial lighting during the day. Additionally, the use of light-colored materials for the interior finishes can help reflect and amplify natural light, further enhancing the overall brightness of the space. Furthermore, steel structures can be designed with shading devices or louvers to control the amount of sunlight entering the building. These devices can be adjusted to block direct sunlight during certain times of the day, preventing overheating and glare while still allowing diffused natural light to enter the space. This helps to maintain a comfortable indoor environment and reduces the need for excessive cooling or shading systems. Overall, through thoughtful design and the incorporation of various elements such as windows, skylights, roof vents, open floor plans, and shading devices, steel structures can be effectively designed to accommodate natural lighting and ventilation, creating a more sustainable and comfortable environment for occupants.

- Q: How are steel structures designed to resist fatigue and cyclic loading?

- Steel structures are designed to resist fatigue and cyclic loading through several methods. Firstly, the design process involves determining the expected loading conditions and stress levels that the structure will experience during its lifetime. This information is then used to establish the appropriate design criteria and fatigue limits. One common approach to enhancing fatigue resistance is to use high-strength steel, which has a greater resistance to cyclic loading compared to lower-grade steels. The material properties, including its yield strength, ultimate strength, and ductility, are carefully considered during the design phase to ensure the structure can withstand cyclic loading without experiencing fatigue failure. Furthermore, the design of steel structures often incorporates various details and features to minimize stress concentrations, which are common sites for fatigue initiation. These features can include smooth transitions, fillets, and the avoidance of abrupt changes in cross-sections. By reducing stress concentrations, the risk of fatigue cracks forming is significantly reduced. Another important aspect of designing steel structures for fatigue resistance is the consideration of load paths. By properly directing and distributing the applied loads, the structure can effectively manage and dissipate the cyclic stresses it experiences. This can involve the use of stiffeners, gussets, and bracing elements to ensure that the loads are transferred efficiently throughout the structure, minimizing localized stress concentrations. Additionally, regular inspections and maintenance are crucial to ensure the continued integrity of steel structures under cyclic loading. Periodic inspections can identify any signs of fatigue damage, such as crack initiation or propagation, allowing for timely repairs or reinforcement before catastrophic failure occurs. In summary, steel structures are designed to resist fatigue and cyclic loading through the selection of appropriate materials, the avoidance of stress concentrations, the optimization of load paths, and the implementation of regular inspections and maintenance. By considering these factors, engineers can ensure that steel structures can withstand the repetitive loading they are subjected to, providing long-lasting and reliable performance.

- Q: How are steel cladding panels installed?

- Steel cladding panels are typically installed using a variety of methods, including direct screw fixing, concealed fixing systems, or standing seam systems. The panels are first measured and cut to size, then fastened to the building's structure using screws or other fasteners. The installation process may also involve sealing joints and applying protective coatings to ensure durability and weather resistance.

- Q: What are the design considerations for steel canopies?

- When designing steel canopies, there are several important considerations that need to be taken into account to ensure a safe and effective structure. These design considerations include: 1. Structural Integrity: The steel canopy must be designed to withstand the loads it will be subjected to, such as wind, snow, and any potential seismic activity. The design should take into account the specific location and environmental conditions to ensure the canopy remains stable and secure. 2. Material Selection: The type and grade of steel used in the canopy's construction is crucial. Factors such as strength, corrosion resistance, and durability need to be considered. The chosen steel should have sufficient strength to bear the load and resist any potential impacts or external forces. 3. Weather Resistance: Canopies are exposed to various weather conditions, including rain, snow, and extreme temperatures. The design should incorporate appropriate measures to ensure water drainage, prevent snow accumulation, and protect against corrosion caused by moisture. 4. Aesthetics: Steel canopies are often used to enhance the visual appeal of a building or space. The design should consider the overall aesthetics, matching the architectural style and ensuring the canopy complements the surrounding environment. 5. Accessibility and Safety: Canopies should be designed with accessibility in mind, ensuring that people of all abilities can comfortably and safely navigate under the structure. Considerations such as clearance height, lighting, and the use of non-slip surfaces should be included in the design. 6. Maintenance and Durability: Steel canopies should be designed for long-term durability and ease of maintenance. This may include features such as protective coatings, easy access for cleaning or repairs, and consideration of the canopy's lifespan. 7. Cost Efficiency: The design should aim to achieve the desired functionality and aesthetics while being mindful of cost. Optimizing the size, shape, and materials used can help achieve a balance between cost and performance. Overall, the design considerations for steel canopies involve a multidisciplinary approach that combines structural engineering, architectural design, weatherproofing, accessibility, and cost optimization. By carefully considering all these factors, a well-designed steel canopy can provide a visually appealing, durable, and functional addition to any building or outdoor space.

- Q: Can steel structures be designed for energy harvesting and renewable energy integration?

- Indeed, it is possible to design steel structures for the purpose of energy harvesting and integrating renewable energy sources. Steel, being a versatile and durable material, can be utilized in various systems that harness renewable energy. For instance, solar panels can be integrated into steel roofs or facades, enabling the structure to generate electricity from solar energy. Furthermore, steel structures can be engineered with wind turbines that capture wind energy. These turbines can be installed on tall steel towers or seamlessly incorporated into the structure's design. Additionally, steel structures can be tailored to accommodate other energy harvesting technologies like piezoelectric systems. By incorporating piezoelectric materials into the structure, mechanical stress or vibrations caused by foot traffic, vehicles, or external forces can be converted into usable electrical energy. Moreover, steel structures can be designed to optimize energy efficiency. By implementing energy-efficient design principles, such as proper insulation, natural lighting, and ventilation systems, steel buildings can reduce their energy consumption and decrease reliance on non-renewable energy sources. In conclusion, steel structures can be effectively engineered to facilitate energy harvesting and integration of renewable energy. By incorporating solar panels, wind turbines, and other energy harvesting technologies, as well as adhering to energy-efficient design principles, steel structures can play a vital role in fostering a sustainable and renewable energy future.

- Q: What is the role of steel canopies in a structure?

- Steel canopies serve multiple roles in a structure. Firstly, they provide protection against the elements, such as rain, snow, and excessive sunlight. By covering a specific area, they prevent these natural elements from directly impacting the space beneath, keeping it dry and providing shade. Additionally, steel canopies enhance the aesthetics of a building. They can be designed in various styles and shapes, allowing architects and designers to incorporate them into the overall visual appeal of the structure. Steel canopies can be customized to match the architectural style, creating a harmonious and visually pleasing design. Furthermore, steel canopies offer functional benefits. They can be used to extend the usable space of a building, providing sheltered areas for outdoor activities or additional storage. For example, a steel canopy can serve as a carport, protecting vehicles from the weather elements. They can also be utilized as covered walkways, entrances, or loading bays, improving accessibility and convenience for occupants or users. Moreover, steel canopies contribute to the structural integrity of a building. Due to the strength and durability of steel, canopies made from this material provide added stability to the overall structure. They can resist high winds, heavy snow loads, and other environmental stresses, ensuring the safety and longevity of the building. In summary, steel canopies play a crucial role in a structure by providing protection against the elements, enhancing the visual appeal, offering functional benefits, and contributing to the structural integrity. Their versatility and durability make them a valuable addition to any building, serving both practical and aesthetic purposes.

- Q: How are steel structures designed for different transportation systems?

- Steel structures for different transportation systems are designed by considering factors such as the type of transportation, load requirements, safety regulations, and environmental conditions. The design process involves analyzing the anticipated loads, such as weight and impact forces, and selecting appropriate steel materials and components. Additionally, structural engineers use computer-aided design software and mathematical models to simulate and optimize the performance of these structures. The goal is to ensure that the steel structures are strong, durable, and capable of withstanding the specific demands of each transportation system.

- Q: What are the common design considerations for steel bridges?

- Some common design considerations for steel bridges include the structural integrity and stability of the bridge, the load capacity it can sustain, the durability and resistance to corrosion, the ease of maintenance and repair, the aesthetics and visual impact, the environmental impact, and the cost-effectiveness of the design.

Send your message to us

High-end Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords