First-class Steel-work in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

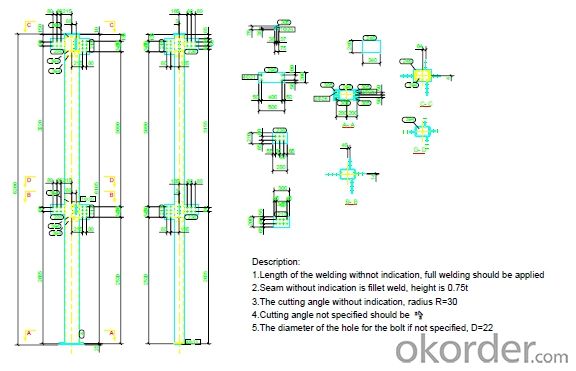

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: What are the different types of steel cladding systems used in building structures?

- There are several types of steel cladding systems used in building structures, including corrugated steel panels, standing seam metal roofing, metal shingles, and insulated metal panels. Each system offers unique benefits and is chosen based on factors such as aesthetics, durability, and energy efficiency requirements.

- Q: How does steel compare to other construction materials, such as concrete or wood?

- Steel is often considered the superior choice when compared to other construction materials like concrete or wood. One of the main advantages of steel is its unmatched strength and durability. It has a high tensile strength, allowing it to withstand heavy loads and resist deformation or structural failure. In comparison, concrete has good compressive strength but lacks the same tensile strength as steel, requiring steel reinforcements to overcome this limitation. Wood, on the other hand, has lower strength and is prone to warping, rotting, or termite damage over time. Additionally, steel offers exceptional versatility in construction. It can be easily molded into various shapes and sizes, allowing for complex architectural designs and flexible construction methods. This adaptability makes steel an ideal material for large-scale projects and unique structures. Steel is also highly resistant to fire, making it a safer choice for construction. It has a high melting point, which means it retains its structural integrity for a longer time during a fire incident. In contrast, wood is highly flammable, while concrete can crack or explode when exposed to high temperatures. Moreover, steel is an environmentally friendly option. It can be recycled indefinitely without losing its properties, reducing the demand for new materials and minimizing waste production. Concrete, on the other hand, requires significant amounts of energy for production, and wood comes from deforestation practices that harm the environment. Despite its numerous advantages, steel does have some drawbacks. It is more expensive than concrete or wood, making it less feasible for smaller-scale projects or budget-constrained situations. Steel structures also require skilled labor and specialized equipment for fabrication and construction, which can increase the overall cost. In summary, steel outperforms other construction materials due to its unparalleled strength, durability, versatility, fire resistance, and sustainability. While it may have higher costs and require specialized expertise, its benefits make it a preferred choice for many construction projects.

- Q: What are the considerations for steel structures in coastal or marine environments?

- There are several considerations for steel structures in coastal or marine environments. Firstly, corrosion is a major concern due to the high moisture content and saltwater exposure. Therefore, selecting corrosion-resistant steel or applying protective coatings is crucial to prevent deterioration. Secondly, the design must account for the harsh environmental conditions, including high winds, waves, and potential impact from floating debris. Proper reinforcement and anchoring techniques should be employed to ensure structural integrity. Additionally, the maintenance and inspection of steel structures in coastal or marine environments should be frequent and thorough to identify any signs of corrosion or damage early on and take necessary preventive measures.

- Q: How are steel structures designed to be resistant to corrosion in acidic environments?

- Steel structures are designed to be resistant to corrosion in acidic environments through various methods. One common approach is to use corrosion-resistant alloys or coatings that provide a protective barrier between the steel and the corrosive environment. Additionally, the design may incorporate proper drainage systems to prevent the accumulation of water or acidic substances, which can accelerate corrosion. Regular maintenance, such as inspections and cleaning, is also crucial to identify and address any signs of corrosion promptly.

- Q: What are the common design considerations for steel structures in parking structures?

- Some common design considerations for steel structures in parking structures include load-bearing capacity, durability, corrosion resistance, fire resistance, seismic resistance, and ease of construction. Additionally, considerations for efficient space utilization, adequate ventilation, lighting, and drainage are also important.

- Q: What are the factors that determine the load-bearing capacity of a steel structure?

- The load-bearing capacity of a steel structure is determined by several factors. Firstly, the design of the structure plays a crucial role. The engineer must consider the type and magnitude of loads that the structure will bear, such as dead loads (the weight of the structure itself) and live loads (the weight of people, furniture, snow, wind, etc.). The design should also account for any potential eccentricities, which refer to the deviations from the ideal and symmetrical loading conditions. Secondly, the quality and strength of the steel used in the structure are essential. Steel's load-bearing capacity depends on its tensile strength, yield strength, and ductility. Tensile strength refers to the maximum stress a material can withstand without breaking under tension. Yield strength is the stress at which a material permanently deforms. Ductility is the ability of a material to deform under tension without fracturing. Higher-quality steels with greater tensile and yield strengths and enhanced ductility can support higher loads. Thirdly, the dimensions and shape of the steel members are crucial factors. The size and cross-sectional area of the members determine their load-carrying capacity. Larger and thicker members can bear more load than smaller ones. Additionally, the shape of the members affects their resistance to bending and buckling. Different shapes, such as I-beams or H-columns, have varying load-bearing capacities due to their different moments of inertia and section moduli. Lastly, the connections between steel members also contribute to the load-bearing capacity. Properly designed and fabricated connections distribute the loads evenly among the individual members, ensuring that the structure functions as a unified system. The type of connections, such as bolted, welded, or riveted, also determines the overall strength and stability of the structure. In conclusion, the load-bearing capacity of a steel structure is determined by various factors, including the design, quality and strength of the steel, dimensions and shape of the members, and the connections between them. By considering these factors, engineers can ensure the structural integrity and safety of steel structures under different load conditions.

- Q: The meaning of UT in steel structure

- Ultrasonic testing (ultrasonic, testing). The use of an object's own or defect's acoustic characteristics to detect the effects of ultrasonic propagation on object defects or certain physical characteristics. The ultrasonic frequency used in ultrasonic testing is between 0.5 and 5 MHz (MHz). The most commonly used ultrasonic test is pulse flaw detection

- Q: What are the factors to consider when designing steel structures for high-rise buildings?

- When designing steel structures for high-rise buildings, several factors must be carefully considered to ensure the safety, stability, and functionality of the building. These factors include: 1. Structural Integrity: The structural integrity of the steel components is of utmost importance. The design must be able to withstand the loads imposed by the building's own weight, as well as external loads such as wind, earthquakes, and live loads. The steel members must be designed to resist bending, shear, and axial forces to prevent any potential failure. 2. Material Selection: The selection of the appropriate steel material is crucial. The steel must have high strength and ductility to handle the stresses induced by the building's height and loads. Typically, high-strength low-alloy steels or carbon steels are used for high-rise buildings due to their excellent mechanical properties. 3. Fire Resistance: Fire resistance is a critical factor in high-rise building design. Steel is inherently fire-resistant, but it can lose strength at high temperatures. Therefore, fire protection measures such as fire-resistant coatings or encasement with fire-resistant materials must be incorporated to ensure the structure maintains its integrity during a fire event. 4. Wind Loads: High-rise buildings are susceptible to strong wind forces due to their height. The design must consider the wind loads acting on the structure and ensure adequate stiffness and strength to resist these forces. Wind tunnel testing and computational fluid dynamics analysis are often employed to accurately determine the wind loads and their effects on the structure. 5. Foundation Design: The foundation of a high-rise building is critical for its overall stability. The design must consider the building's weight, the soil conditions, and potential settlement to ensure a safe and stable foundation system. 6. Construction Constraints: The construction process of high-rise buildings can be challenging. The design must account for these constraints, including limited access to the site, transportation of materials, and construction sequencing. The steel members must be designed in a way that facilitates efficient and safe construction methods. 7. Sustainability: Incorporating sustainable design principles is increasingly important in modern construction. Considerations such as the use of recycled steel, energy-efficient design, and the potential for future re-use or recycling of the structure should be addressed during the design phase. In conclusion, designing steel structures for high-rise buildings requires careful consideration of various factors, including structural integrity, material selection, fire resistance, wind loads, foundation design, construction constraints, and sustainability. These factors must be thoroughly analyzed and integrated into the design to ensure a safe, efficient, and durable high-rise building.

- Q: How are steel structures designed for airport terminals?

- Steel structures for airport terminals are typically designed using a combination of architectural and engineering principles. The design process involves considering factors such as the terminal's layout, functionality, and required capacity. Structural engineers work closely with architects to determine the optimal steel framework, ensuring it can withstand the required loads, such as the weight of the roof, equipment, and potential seismic or wind forces. Additionally, considerations are made for the efficient use of space, the incorporation of necessary facilities, and adherence to safety regulations. Overall, the design of steel structures for airport terminals aims to create a durable, functional, and visually appealing space for passengers and staff.

- Q: How are steel structures used in the construction of stadiums and arenas?

- Steel structures are extensively utilized in the construction of stadiums and arenas due to their numerous advantages. The framework or skeleton of the building is one primary application of steel in these structures. Steel offers exceptional strength and durability, enabling the creation of large open spaces and wide spans without the need for numerous supporting columns or walls. This results in unobstructed views for spectators and maximizes seating capacity. Moreover, steel structures can be conveniently fabricated off-site and then assembled on-site, leading to reduced construction time and costs. The prefabrication process ensures construction of high quality and precision, resulting in a safe and reliable structure. Steel also possesses excellent fire resistance properties, making it an ideal material for stadiums and arenas where safety is of paramount importance. Another advantage of steel structures in stadium construction lies in their flexibility and adaptability. Steel can be easily modified or expanded upon in case future renovations or additions are required. This proves particularly advantageous for stadiums and arenas that may need to accommodate changing needs such as increased seating capacity or the incorporation of new technologies. Furthermore, steel structures are environmentally friendly. Steel is a recyclable material, which means it can be reused or repurposed at the end of its lifespan. This practice reduces waste and contributes to sustainable construction practices. In conclusion, steel structures play a critical role in the construction of stadiums and arenas by providing strength, durability, flexibility, and sustainability.

Send your message to us

First-class Steel-work in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords