High-end Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

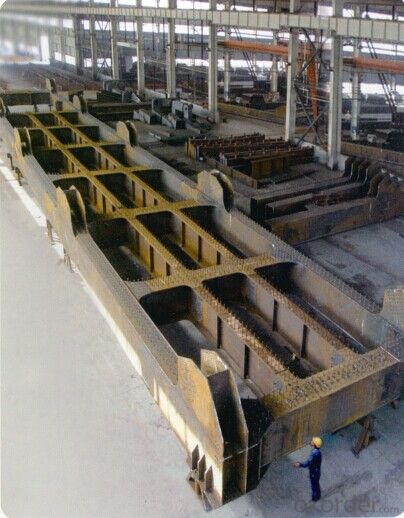

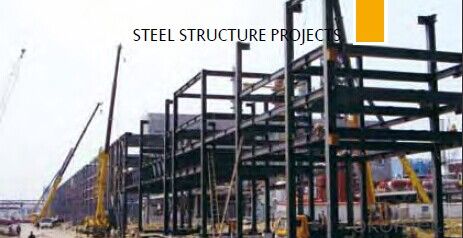

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

For the Steel structure project of Upper part of external

piperack for air separation and gasifying facilities of

460,000 tons MTO (Methanol to Olefins) project in

Duolun, we provide about 4,500 tons steel structure. It

is a heavy chemical indusry of national energy project.

- Q: How are steel structures designed for foundation settlement control?

- Various methods can effectively control foundation settlement in steel structures. One approach commonly employed is the utilization of flexible connections between the steel structure and the foundation. These connections, such as elastomeric bearings or steel sliding plates, allow for slight movements and rotations of the structure without transferring excessive loads to the foundation. They are specifically designed to absorb and dissipate the forces generated by settlement, thus minimizing its impact on the overall stability of the structure. In addition, steel structures can incorporate adjustable supports or jacks to compensate for differential settlement. These supports can be adjusted to raise or lower specific areas of the structure, ensuring that it remains level and balanced despite any settlement that may occur. Another technique used in steel structure design to control foundation settlement is the inclusion of structural redundancy. This involves designing the structure with redundant members and connections to provide alternate load paths in case settlement occurs. By distributing the load across multiple structural elements, the effects of settlement can be minimized, and the overall stability of the structure can be maintained. Furthermore, proper geotechnical investigation and analysis play a crucial role in designing steel structures for foundation settlement control. By gaining a comprehensive understanding of the soil conditions and potential settlement patterns at a site, engineers can tailor the design to account for these factors. This may involve implementing additional foundation measures, such as deep foundations or ground improvement techniques, to mitigate settlement risks. In summary, steel structures can be designed to effectively control foundation settlement through the use of flexible connections, adjustable supports, structural redundancy, and appropriate geotechnical analysis. These measures ensure that the structural integrity of the steel construction is maintained, even in the presence of settlement.

- Q: What are the considerations for designing steel pedestrian bridges for parks and trails?

- When designing steel pedestrian bridges for parks and trails, there are several key considerations to keep in mind. First and foremost, the safety of pedestrians should be the top priority. This involves ensuring that the bridge is structurally sound and can support the anticipated load, as well as incorporating appropriate handrails and non-slip surfaces. Additionally, the bridge should be designed to be accessible to people of all abilities, including those with disabilities or limited mobility. The aesthetics of the bridge should also be considered, as it should blend harmoniously with the natural surroundings and enhance the overall park or trail experience. Finally, factors such as durability, maintenance requirements, environmental impact, and cost-effectiveness should also be taken into account during the design process.

- Q: How are steel structures used in the construction of hotels?

- Steel structures are widely used in the construction of hotels due to their numerous advantages. Firstly, steel is a strong and durable material that can withstand heavy loads, making it ideal for constructing multi-story hotels. The high strength-to-weight ratio of steel allows for the creation of large open spaces, enabling architects to design spacious and aesthetically pleasing hotel interiors. Additionally, steel structures are highly resistant to fire, earthquakes, and other natural disasters, providing enhanced safety for hotel guests and staff. The use of steel in the construction of hotels also ensures a shorter construction timeline, as steel components can be pre-fabricated off-site and quickly assembled on-site. This reduces the overall construction time, allowing hotels to be completed and operational in a shorter period. Moreover, steel structures are flexible and can be easily modified or expanded in the future. This is particularly beneficial for hotels that may require renovations or expansions as their business grows. Steel also allows for the integration of various architectural features, such as large windows or cantilevered structures, adding a unique and modern touch to hotel designs. In terms of sustainability, steel is a recyclable material, making it an eco-friendly choice for hotel construction. It can be reused or repurposed, reducing the environmental impact associated with building materials. Additionally, steel structures can be designed to enhance energy efficiency by incorporating insulation and efficient HVAC systems, thereby reducing the hotel's energy consumption and operational costs. Overall, the use of steel structures in the construction of hotels offers numerous benefits, including strength, durability, safety, flexibility, sustainability, and reduced construction time. These advantages make steel an ideal choice for hotel developers and owners, ensuring the creation of high-quality and efficient hotel buildings.

- Q: How are steel structures used in the construction of concert halls?

- Steel structures are commonly used in the construction of concert halls as they provide the necessary strength and support to accommodate large open spaces, heavy equipment, and intricate architectural designs. Steel beams and columns are used to create the framework of the building, allowing for long spans and high ceilings. Additionally, steel is fire-resistant, which ensures the safety of the concert hall and its occupants. Overall, steel structures play a crucial role in creating durable, versatile, and visually appealing concert halls.

- Q: What are the factors that determine the load-bearing capacity of a steel structure?

- The load-bearing capacity of a steel structure is determined by several factors. Firstly, the design of the structure plays a crucial role. The engineer must consider the type and magnitude of loads that the structure will bear, such as dead loads (the weight of the structure itself) and live loads (the weight of people, furniture, snow, wind, etc.). The design should also account for any potential eccentricities, which refer to the deviations from the ideal and symmetrical loading conditions. Secondly, the quality and strength of the steel used in the structure are essential. Steel's load-bearing capacity depends on its tensile strength, yield strength, and ductility. Tensile strength refers to the maximum stress a material can withstand without breaking under tension. Yield strength is the stress at which a material permanently deforms. Ductility is the ability of a material to deform under tension without fracturing. Higher-quality steels with greater tensile and yield strengths and enhanced ductility can support higher loads. Thirdly, the dimensions and shape of the steel members are crucial factors. The size and cross-sectional area of the members determine their load-carrying capacity. Larger and thicker members can bear more load than smaller ones. Additionally, the shape of the members affects their resistance to bending and buckling. Different shapes, such as I-beams or H-columns, have varying load-bearing capacities due to their different moments of inertia and section moduli. Lastly, the connections between steel members also contribute to the load-bearing capacity. Properly designed and fabricated connections distribute the loads evenly among the individual members, ensuring that the structure functions as a unified system. The type of connections, such as bolted, welded, or riveted, also determines the overall strength and stability of the structure. In conclusion, the load-bearing capacity of a steel structure is determined by various factors, including the design, quality and strength of the steel, dimensions and shape of the members, and the connections between them. By considering these factors, engineers can ensure the structural integrity and safety of steel structures under different load conditions.

- Q: How are steel structures used in elevators and escalators?

- Steel structures are an integral part of elevators and escalators, providing the necessary support and stability for these transportation systems. In elevators, steel is used to construct the shaft, which is the vertical enclosure where the elevator car moves up and down. The steel shaft ensures the safety and structural integrity of the elevator, as it is designed to withstand the weight of the elevator car and its occupants. Additionally, steel is used in the construction of the elevator car itself. The car is typically made of steel panels and frames, which provide strength and durability. Steel is chosen for this purpose due to its high tensile strength, allowing it to support heavy loads. Steel is also resistant to corrosion, ensuring the longevity of the elevator car and minimizing maintenance requirements. In escalators, steel structures are used in a similar manner. The escalator truss, which is the framework that supports the moving steps, is typically made of steel. The truss provides the necessary rigidity and strength to support the weight of the steps and passengers. Steel is preferred for this application due to its high load-bearing capacity and resistance to deformation. Furthermore, steel is used in the construction of the escalator steps themselves. The steps are typically made of steel plates, which are sturdy and durable. Steel steps can withstand continuous foot traffic and are designed to be slip-resistant for passenger safety. Overall, steel structures play a crucial role in elevators and escalators, providing the necessary support, stability, and durability for these transportation systems. The use of steel ensures the safety of passengers and the efficient operation of these vertical transportation solutions.

- Q: How are steel structures designed for wind-induced vibrations?

- Steel structures are designed for wind-induced vibrations by considering various factors such as wind speed, direction, and frequency. Engineers use dynamic analysis and wind tunnel testing to determine the structural response to wind loads. They also incorporate measures like aerodynamic shaping, dampers, bracing, and stiffening elements to minimize vibrations and ensure the safety and stability of the steel structure.

- Q: What are the key considerations when designing steel bridges?

- When designing steel bridges, there are several key considerations that engineers must take into account to ensure the safety, durability, and efficiency of the structure. 1. Load capacity: The bridge must be designed to withstand the various loads it will be subjected to, such as dead loads (the weight of the bridge itself), live loads (traffic, pedestrians, vehicles), and environmental loads (wind, earthquakes, temperature variations). The engineer must determine the maximum load that the bridge will experience and design the structure accordingly. 2. Structural integrity: Steel bridges need to be designed to maintain their structural integrity over time. This includes considering factors such as fatigue, corrosion, and material deterioration. The design should incorporate appropriate measures to prevent or mitigate these issues, such as corrosion-resistant coatings, regular maintenance, and inspections. 3. Span length and geometry: The length of the bridge span and its overall geometry play a crucial role in the design process. Longer spans require stronger and more resilient materials and structural systems. The bridge's geometry affects its aesthetics, functionality, and the ease of construction. 4. Environmental impact: Engineers must consider the potential environmental impact of the bridge design. This includes minimizing the overall carbon footprint of the construction process, reducing energy consumption during the bridge's lifespan, and ensuring that the design does not harm the surrounding ecosystem or disrupt natural water flow. 5. Construction feasibility: The design should take into account the practicality and feasibility of construction. Factors such as site accessibility, construction techniques, and fabrication methods should be considered to ensure that the bridge can be built efficiently and within budget. 6. Aesthetics and community impact: The visual appeal of a steel bridge is an important consideration. The design should blend harmoniously with the surrounding environment and the community's aesthetic preferences. Additionally, the bridge's impact on the local community, including traffic flow, pedestrian access, and noise levels, should be taken into account during the design process. 7. Cost-effectiveness: The design should aim to achieve the desired functionality and safety while also being cost-effective. This includes optimizing material usage, minimizing maintenance requirements, and considering the lifecycle cost of the bridge. Overall, designing steel bridges requires a thorough understanding of structural engineering principles, environmental considerations, construction feasibility, and community needs. By carefully considering these key factors, engineers can create safe, durable, efficient, and aesthetically pleasing steel bridges.

- Q: What are the factors to consider when choosing steel for a structure?

- There are several factors to take into account when deciding on the steel to be used in a structure. Firstly, the utmost importance lies in the load-bearing capacity of the steel. It must have the ability to withstand the weight and forces imposed on the structure, taking into consideration the maximum expected load and the nature of the load, whether it is static or dynamic. Secondly, it is necessary to assess the durability and resistance to corrosion of the steel. Steel structures are often subjected to various environmental conditions, including moisture, chemicals, and temperature fluctuations. Therefore, it is advisable to select a steel grade with high corrosion resistance, such as stainless steel or weathering steel, in order to increase the longevity of the structure and minimize maintenance requirements. Another crucial factor to consider is the cost-effectiveness of the steel. The initial cost of the steel, including the material itself and the fabrication process, should be taken into account. In addition, long-term costs, such as maintenance and potential repairs, should also be considered. It is important to find a steel grade that strikes a balance between cost and performance. The fabrication and construction process also play a significant role in the selection of steel. The availability and accessibility of the steel grade, as well as its ease of fabrication and installation, can have an impact on the project timeline and budget. It is important to choose a steel grade that is readily available and can be efficiently fabricated and erected. Furthermore, the aesthetic requirements of the structure may influence the choice of steel. Some steel grades offer a wide range of finishes and surface treatments, allowing for customization and architectural design possibilities. Taking into consideration the desired appearance and visual impact can help guide the selection process. Lastly, compliance with applicable codes and regulations is vital. The chosen steel grade must meet the required standards and regulations for structural safety. It is crucial to consult with structural engineers and adhere to local building codes in order to ensure the structural integrity of the project. In conclusion, when choosing steel for a structure, it is important to consider factors such as load-bearing capacity, durability, cost-effectiveness, fabrication and construction requirements, aesthetic considerations, and compliance with codes and regulations. Evaluating these factors will assist in selecting the most suitable steel grade for the specific needs of the project.

- Q: How are steel structures used in the construction of hotels and resorts?

- Hotels and resorts often rely on steel structures for their construction, as they offer a multitude of advantages. Firstly, steel is a remarkably robust and long-lasting material, making it perfect for supporting large and intricate buildings like hotels and resorts. By employing steel, these structures can endure severe weather conditions, earthquakes, and other natural disasters, ensuring a safe and secure environment for guests. Furthermore, steel structures allow for great design flexibility, granting architects and engineers the freedom to create unique and visually striking buildings. Steel's versatility permits the incorporation of open floor plans, expansive spans, and diverse architectural features, such as glass facades and grand atriums. This adaptability also facilitates easy expansion or modification of the buildings in the future, accommodating the ever-changing needs of hotels and resorts. Additionally, steel structures enable faster construction times compared to traditional building materials. The components of a steel structure can be pre-fabricated off-site, reducing on-site construction time. This not only leads to cost savings but also allows hotels and resorts to commence operations sooner, generating revenue at an earlier stage. Moreover, steel is an environmentally friendly material. It boasts high recyclability, enabling the reutilization or repurposing of steel components at the end of a building's life cycle. The use of steel in construction also decreases the demand for timber, thereby aiding in the preservation of forests and ecosystems. In conclusion, the widespread use of steel structures in the construction of hotels and resorts can be attributed to their strength, durability, design flexibility, expedited construction times, and environmental benefits. These structures provide a sturdy foundation for the creation of visually pleasing, secure, and sustainable buildings that cater to the ever-evolving requirements of the hospitality industry.

Send your message to us

High-end Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords