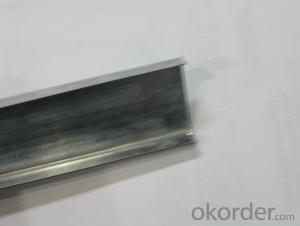

Galvanized cowl

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Diameter: Φ 100mm Φ 125mm Φ 160mm Φ 200mm Φ 250mm

We are one of the biggest and professinal manufacturer of ventilation products including INLINE FANS, SPEED CONTROLLER, CARBON FILTER, PIPE FITTING, etc in China. We can provide you with high quality & competitive price & excellent service. Welcome to visit our Group Company at any time.

Model NO.:150mm

Material:Metal

Type:Centrifugal Fan

Certification:ISO, SGS

Electric Current Type:No Power

Mounting:The Chimney, The Tube, and The Roof

Blade Material:Stainless Steel

No Maintenance or Operating Costs:Water and Dust Proof

Improves Air Quality:Improves Productivity

Material: Stainless Steel, Color Coated:Type: 100mm/120mm/125mm/150mm/250mm/300mm

Delivery Time:Very Fast, Within 10 Days

Export Markets:Global

Trademark:WT

Packing:Box

Standard:The international standard

Origin:China

HS Code:84148090

Production Capacity:100000PCS/Per Month

1. Material: Stainless steel (SS201, SS304), Color steel, Aluminum, Galvanized steel.

Usually: Stainless steel, color steel. Please you choose according your requests. We can produce.

2. Type/size: 100MM/125MM/300MM/350MM/400MM/420MM/450MM/500MM/560MM/600MM/680MM/760MM/800MM/900MM/1000MM/1200MM.

Usually: 100mm/120mm/125mm/150mm/250mm/300mm/350mm/450mm/500mm/600mm/680mm/900mm/1000mm/1200mm.

We can according your requests to produce.

3. Products advantage:

1). No maintenance or operating costs

2). Water and dust proof

3). Improves air quality

4). Improves productivity

4. The more information of products:

1). The structure of the high quality,

2). The precision of the running device,

3). Green environmental protection ventilation equipment,

4). Applicability widely. All kinds of industrial factory building contour plate light steel structure roofing, concrete roof can also be installed.

- Q: What are the common design considerations for steel retaining walls?

- There are several common design considerations that need to be taken into account when designing steel retaining walls. These considerations include: 1. Retaining wall height: The height of the retaining wall will determine the type and thickness of steel members required to resist the lateral earth pressure. The taller the wall, the more robust the steel members need to be. 2. Lateral earth pressure: The lateral earth pressure exerted on the retaining wall is a critical factor in design. Factors such as soil type, slope angle, and water content need to be considered to determine the appropriate level of lateral support needed. 3. Foundation conditions: The type and condition of the foundation where the retaining wall will be constructed is crucial. Factors such as soil bearing capacity, soil settlement, and potential for soil erosion need to be assessed to ensure a stable foundation for the retaining wall. 4. Drainage: Proper drainage behind the retaining wall is essential to prevent the buildup of hydrostatic pressure. Adequate provision for drainage needs to be incorporated into the design, including weep holes, gravel backfill, and drainage pipes. 5. Wall geometry and configuration: The shape and configuration of the retaining wall will affect its stability and structural integrity. Factors such as wall thickness, reinforcement spacing, and the presence of any curves or bends need to be considered during the design process. 6. Seismic considerations: In areas prone to earthquakes, the retaining wall design needs to incorporate seismic design principles to withstand ground motions. This may involve additional reinforcement, anchorage, or special construction techniques to ensure the wall's stability during seismic events. 7. Durability and corrosion protection: Steel retaining walls are susceptible to corrosion, especially in environments with high moisture or exposure to saltwater. Proper coatings or galvanization should be applied to protect the steel members from rust and corrosion, ensuring the longevity of the retaining wall. By considering these design considerations, engineers can develop steel retaining walls that are structurally sound, durable, and capable of withstanding the forces exerted by the surrounding soil and other external factors.

- Q: How are steel structures used in the construction of cultural centers and museums?

- Steel structures are commonly used in the construction of cultural centers and museums due to their strength, versatility, and ability to create large open spaces. Steel beams and columns provide support for the building, allowing for expansive interiors and the incorporation of unique architectural designs. Additionally, steel's durability and resistance to fire make it an ideal material for preserving and protecting valuable artifacts and exhibits within these cultural institutions.

- Q: How does the design of a steel structure affect its stability?

- The design of a steel structure greatly influences its stability. Factors such as the type of connections, bracing systems, and the overall structural layout can impact the structure's ability to resist various loads and forces. A well-designed steel structure will consider factors like load distribution, wind and seismic resistance, and the efficient transfer of loads to the foundation. Adequate bracing and connections ensure that the structure can withstand external forces and prevent collapse or deformation. Therefore, a carefully planned design is crucial for ensuring the stability and overall structural integrity of a steel structure.

- Q: What are the different types of steel foundations?

- There are several types of steel foundations commonly used in construction, including drilled pier foundations, helical pile foundations, and steel H-pile foundations.

- Q: How are steel structures designed to be resistant to electromagnetic interference?

- Steel structures are designed to be resistant to electromagnetic interference by incorporating various measures such as grounding, shielding, and proper layout of electrical components. Grounding helps to dissipate any unwanted electrical energy and divert it safely into the ground. Shielding involves using metallic barriers or coatings to block or absorb electromagnetic waves. Additionally, careful placement of electrical components and wiring ensures minimal interference and proper separation between sensitive equipment and potential sources of electromagnetic interference.

- Q: What are the common design considerations for steel staircases?

- There are several common design considerations for steel staircases that designers and architects need to take into account to ensure optimal functionality, safety, and aesthetic appeal. Some of these considerations include: 1. Structural stability: Steel staircases need to be designed to provide sufficient structural stability and support the weight of individuals using the stairs. The design should include appropriate calculations for the load-bearing capacity of the steel structure. 2. Building codes and regulations: Designers must adhere to local building codes and regulations governing staircases, including requirements for riser height, tread depth, handrail height, and other safety measures. Compliance with these regulations is essential to ensure the safety of users. 3. Ergonomics and user comfort: The design of steel staircases should prioritize user comfort and ergonomics. Factors such as the angle of inclination, step dimensions, and handrail placement need to be carefully considered to provide a comfortable and safe experience for users. 4. Slip resistance: Steps and landing surfaces should be designed to offer adequate slip resistance, especially in areas where there may be moisture or other potential slip hazards. This can be achieved through the use of non-slip materials or surface treatments. 5. Accessibility: Designers should consider accessibility requirements to ensure that the staircase can be easily used by individuals with disabilities or limited mobility. This may involve incorporating features such as handrails, ramps, or lifts. 6. Durability and maintenance: Steel staircases need to be designed to withstand regular use and potential environmental factors such as corrosion, humidity, or extreme temperatures. Proper coatings or finishes can be used to protect the steel from these elements and reduce maintenance requirements. 7. Aesthetics: While functionality and safety are paramount, the aesthetic appeal of steel staircases should not be overlooked. Designers can incorporate various finishes, colors, and materials to create visually pleasing staircases that complement the overall design of the space. In summary, when designing steel staircases, considerations such as structural stability, compliance with building codes, user comfort, slip resistance, accessibility, durability, and aesthetics should all be taken into account to create a safe and visually appealing staircase that meets the needs of its users.

- Q: How are steel structures designed to provide adequate access and egress?

- Steel structures are designed to provide adequate access and egress through a variety of methods. Firstly, the design of steel structures takes into consideration the placement and size of doors and windows. These openings are strategically placed to ensure easy and efficient movement in and out of the structure. In addition, stairs and ramps are often incorporated into the design to provide safe and accessible means of moving between different levels of the structure. These elements are designed with proper dimensions, handrails, and non-slip surfaces to ensure the safety of those using them. Furthermore, steel structures can be equipped with elevators and lifts to provide accessibility for individuals with mobility impairments. These vertical transportation systems are designed to comply with relevant accessibility standards and regulations, ensuring that everyone can easily navigate the structure. Moreover, the design of steel structures also considers the placement of emergency exits and evacuation routes. These exits are strategically located and designed to provide a clear and unobstructed path to safety during emergencies. Overall, the design of steel structures prioritizes the provision of adequate access and egress by carefully planning the placement and design of doors, windows, stairs, ramps, elevators, and emergency exits. This ensures that individuals can move in and out of the structure efficiently and safely.

- Q: What are the considerations when designing steel structures for hotels and resorts?

- When designing steel structures for hotels and resorts, several key considerations need to be taken into account. Firstly, the load-bearing capacity of the steel structure must be carefully calculated to ensure it can support the weight of the building, including all the furniture, fixtures, and occupants. Additionally, the design should prioritize flexibility and adaptability to accommodate the hotel's changing needs and potential future expansions. The layout and configuration of the structure should allow for easy reconfiguration of rooms and spaces as required. Furthermore, the steel structure should be designed to withstand the specific environmental conditions of the location, such as high winds, seismic activity, or extreme temperatures. Adequate insulation and weatherproofing measures should also be incorporated to ensure guest comfort and energy efficiency. Fire safety is another crucial consideration. Steel structures should be designed with appropriate fire-resistant materials and systems to meet local building codes and ensure the safety of occupants. Lastly, the aesthetics and overall design of the steel structure should align with the desired theme, branding, and ambiance of the hotel or resort, creating a visually appealing and inviting environment for guests.

- Q: What are the considerations for steel structure design in sustainable communities?

- To ensure sustainability in steel structure design for communities, it is important to take into account several key factors: 1. Material Selection: The choice of steel for the structure plays a critical role in sustainability. Opting for recycled or locally sourced steel can significantly reduce the project's carbon footprint. It is also recommended to use steel with high recycled content and low embodied energy to minimize environmental impact. 2. Energy Efficiency: Incorporating energy-efficient design features is essential for sustainable steel structures. This can include optimizing insulation to reduce heating and cooling loads, utilizing natural ventilation and daylighting to minimize the need for artificial lighting and HVAC systems, and implementing renewable energy sources like solar panels. 3. Lifecycle Analysis: Conducting a thorough analysis of the steel structure's lifecycle is important to evaluate its environmental impact. This analysis should consider factors such as raw material extraction, manufacturing, transportation, construction, maintenance, and end-of-life recycling or disposal. By understanding the lifecycle impact, designers can make informed decisions to minimize environmental harm. 4. Structural Efficiency: Designing structurally efficient steel structures is crucial for sustainability. This involves optimizing the design to minimize material usage while maintaining structural integrity. Advanced modeling and analysis techniques can help engineers reduce the amount of steel required, resulting in lower carbon emissions and embodied energy. 5. Adaptability and Flexibility: Designing steel structures with adaptability and flexibility in mind allows for future modifications and repurposing. This reduces the need for demolition and reconstruction, minimizing waste and resource consumption. Creating structures that can easily accommodate changing needs and technological advancements is essential for long-term sustainability. 6. Local Context and Community Engagement: Understanding the local context and engaging with the community are vital for designing sustainable steel structures. By considering local climate conditions, cultural preferences, and community needs, designers can create structures that are better suited for the specific context, ensuring optimal performance and acceptance by the community. In conclusion, designing sustainable steel structures in communities requires careful consideration of material selection, energy efficiency, lifecycle analysis, structural efficiency, adaptability, and community engagement. By addressing these factors, designers can create environmentally responsible and resilient structures that contribute to the overall sustainability of the community.

- Q: What are the factors influencing the choice between steel and concrete structures?

- The choice between steel and concrete structures is influenced by several factors, including cost, design flexibility, construction speed, durability, and environmental impact. One of the primary factors influencing the choice is cost. While steel structures often have a higher initial cost than concrete structures, they can offer significant long-term savings due to their durability and ease of maintenance. Concrete structures, on the other hand, have a lower initial cost but may require more frequent repairs and maintenance, which can increase their life cycle cost. Design flexibility is another crucial factor. Steel structures offer greater flexibility in terms of shape, span, and height, allowing architects and engineers to create innovative and complex designs. Concrete structures, although less flexible, can still accommodate a wide range of architectural styles and can be molded into various shapes using formwork. Construction speed is also a significant consideration. Steel structures are typically quicker to erect than concrete structures since they are fabricated off-site and assembled on-site. This can lead to reduced construction time and cost, making steel structures more suitable for projects with tight schedules. Concrete structures, on the other hand, require on-site casting and curing, which can result in longer construction periods. Durability is an essential factor, particularly in areas prone to extreme weather conditions or seismic activity. Steel structures have high strength and resistance to corrosion, making them suitable for withstanding earthquakes, hurricanes, and other natural disasters. Concrete structures, while generally durable, may require additional reinforcement to achieve the same level of strength and resilience. Environmental impact is also a consideration in the choice between steel and concrete structures. Steel is a highly recyclable material, and using recycled steel in construction can significantly reduce its carbon footprint. Concrete, on the other hand, has a higher carbon footprint due to the energy-intensive process of cement production. However, advancements in concrete technology, such as the use of supplementary cementitious materials and carbon capture, are being explored to mitigate its environmental impact. In conclusion, the choice between steel and concrete structures is influenced by factors such as cost, design flexibility, construction speed, durability, and environmental impact. Each material offers unique advantages and considerations, and the decision should be based on the specific requirements and constraints of the project.

Send your message to us

Galvanized cowl

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches