Drop in Ceiling Grid for False Ceiling 38H Popular

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Grid ceiling is one of the materials for ceiling system.It has various patterns and beautiful designs, and could be installed optionally to be more fashionable. Moreover, it's very easy to be installed and disassembled.So these series are your ideal decorating material.

Product Applications:

1) Supermarket, marketplace

2) Service station, toll station

3) Underground, air port, bus station

4) School, office, meeting room

5) Hall, corridor and toilet

6) Sport center

7) Office, store, plaza

8) Hotel, restaurant, kitchen

9) Hospital

Product Advantages:

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Re-cycled Material which is meet the environment protection policy in the world.

4. Using fire proof material to assure living safety.

5. Can be installed according to practical demands

Main Product Features:

1) Surface smoothness and easy cleaning

2) High precision, lighter weight, higher strength, better rigidity

3) Strong corrupt proof, weather proof and chemical

4) Easy to match lamps or other ceiling parts

5) Flexible suspension system make each ceiling tiles easy install and disconnect

6) Various patterns are available according to your needs

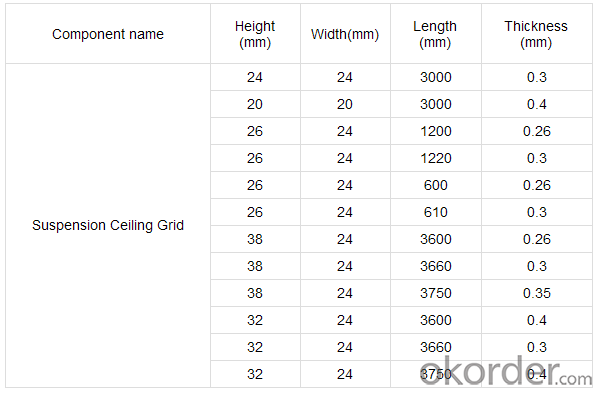

Product Specifications:

FAQ:

Q:How many the warranty years of your products?

A:15 years for indoor used,20 years for ourdoor used.

Q:Can you show me the installation instruction?

A:Yes,our engineering department is in charge of helping your installation.any question,you can let me know.

Images:

- Q: There are several layers of ladder when it is linked directly with the big core board, or how to do? Need to be fixed with wooden square?

- Light steel keel ceiling shape in the corner can be used Daxin board slot. Light steel keel ceiling generally with gypsum board, calcium silicate board, etc., can make any shape, like a light-like strip, round, ring, oval and other shapes, light steel keel has Flexibility, through the designer's unique vision of the unique design, coupled with the master craftsman craftsmen, fine fine chisel, light steel keel gypsum board combination can make a variety of perfect ceiling

- Q: I am using Dutch Boy Ceiling Solutions, the kind that goes on purple and dries white. I primed with FastPrime over new drywall. I put one coat of the DB on and it looks like poo. I painted in grids, but got uneven coverage and you can tell where the drywall tape was. Maybe the roller I used was wrong for the app? Or did I just do a crummy job. I have painted many a room before, but not many ceilings.

- use primer than paint it

- Q: Looking at putting in a drop ceiling...someone said they saw one at Menards that is supposed to fit tight to the rafters...has anyone seen this or used it?? Likes/dislikes??

- How about just swapping the ceiling panels. If no one has complained lately maybe the office manager doesn't remember where the outlet is located. The air that would have come directly down on her would end up in the ceiling area but would fall down through the moved panel since it's cold. That way everyone else would still be cool and if the manager looked up he would not see any blockage. No finger print now and the less people that know about it the better..... Sounds like you have a real jerk for an office manager, drunk with power.

- Q: It is good when the ceiling is light steel keel and wood keel

- Light steel keel and wood keel each have their own advantages, but from all aspects of consideration or light steel keel advantages more: Light steel keel is not deformed, not damp, but no wood light and flexible shape, wood keel flammable, easy to mold rotten, not fire, but the wooden keel to do easy to shape, so you can choose according to the situation keel

- Q: I would like to finish my basement (pay to have it done) but to do it a little at a time for financial reasons. Would like dropped ceiling and wirng done first. Thanks!

- The wall angle for the drop ceiling must go on the finished wall.You have to do the walls first.

- Q: Light steel keel or paint keel good kitchen ceiling, light steel keel and paint keel, I do not know which is good?

- Two kinds of keel use is not the same. Light steel keel is mainly used for gypsum board, calcium silicate, woodworking board and other sheet metal cladding keel, after the completion of intuitive can not see, covered by the panel. The paint keel is used for the fixing of aluminum plate, grit board, gypsum board and other assembled plate. These panels are usually processed into fixed size box (300 or 600), and the box is composed of box and plate. , After the completion of intuitive can see the paint keel.

- Q: Large area of the hall light steel keel ceiling installation keel how to leveling is the pull line so long how could pull up

- Large area of light steel keel ceiling, we are leveling with infrared level. Make a bracket fixed in the light steel keel 4,50 cm on the wall, made a pair of bone, made of wood T-shaped, hanging in the bar near the main bone, with reference to the wall fixed wooden side height Leveling.

- Q: In carpentry and drywall when they refer to Black Iron on hanging ceilings what do they mean?

- Black iron is the frame below the slab from which the hung ceiling grid or drywall studs are suspended and to which partition caps may be fastened. It defines maximum ceiling height for commercial tenant work. Piping, ductwork , and electrical work in the ceiling are also fastened to/routed through this supporting fame work.

- Q: Is there any requirements regarding hard wired smoke detectors on a suspended ceiling?I know luminaires are supposed to be properly secured to the grid, do smoke and CO detectors need to be? If so how?Right now, all I have is some old work boxes for the splices.I'm looking for a correct answer, I'm not going to cut corners.NEC code references are a plus.

- Yes there are: Because the hard wired smoke detectors are connected to 120 volts they fall under the NEC Wiring methods NEC Article 300. The specific location is 300.11 It gives all of the rules about not using the grid support wires as a method of sole support. You do have to add a support wire the same as a luminary. The best way to attach the old work boxes is to use a bracket called a T-bar they are made by Caddy and several other companies. You also have to make sure that the suspended ceiling is not being used as a return air path for a forced air system because the NFPA 72 states that the minimum distance from a return air to a smoke or CO2 detector is 3 feet. Hope this answers your question :)

- Q: Do not know who can tell me ah

- Set the hanging bar on the beam 1) Hanging rods should be straight and have sufficient carrying capacity. When the embedded bar need to take a long time, must be lap welding, Welds should be evenly full. 2) the length of the boom from the main keel shall not exceed 300mm, otherwise the boom should be increased. 3) ceiling lamps, tuyere and maintenance mouth should be set up additional boom.

Send your message to us

Drop in Ceiling Grid for False Ceiling 38H Popular

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords