Slimline Ceiling Grid Hot Sale Flat Groove Main Tee H38

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

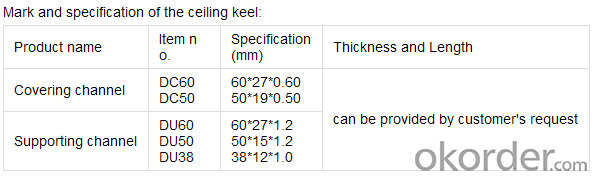

Product Specifications:

Image

- Q: Φ8 light steel keel boom is how much?

- Do pull the experiment to know the top burst out of the boom will not break off In the beam generally around 300KG

- Q: Light steel keel gypsum board ceiling flat flat how much money a square meter

- The cost of materials should be about 55 yuan per square meter. I hope my solution will help you

- Q: 120mm light steel keel wall keel model is how much

- Light steel keel routine with 75 partition keel, plus 2 layer 12 thick gypsum board is nearly 100 thickness

- Q: Material used in False Ceiling?

- A false or dropped ceiling can be made of various materials. Most commonly, they are made of ceiling tiles or panels that are suspended from a grid of wires and tracks.

- Q: I'm not sure if lots of stores sell it, but I've always wanted something to put on the floor that would project stars and space onto my ceiling. I'm not sure what that's called or where I could buy one. Anyone have any ideas?

- Project Stars On Ceiling

- Q: In a school auditorium, what would make part of the ceiling fall other than from age or some type of mold problem? The ceiling, supposedly, only fell once but it was a decent size piece. It has been unusable for almost a year now, I think there is more to the story...

- Is it a suspended grid acoustical ceiling? This shouldn't happen unless the tiles get wet and soak up water or the border tiles were cut too short, or the installer didn't use pop rivets to secure the grid to the molding.

- Q: Double-sided 200 light steel keel gypsum board wall how much money a square

- Use 150 light steel keel, double-sided double-layer 12mm gypsum board, do paint, you can reach 200mm specifications.

- Q: Living room ceiling, light steel keel gypsum board, the minimum can be hanging?

- Height of the lowest: height, then, light steel keel gypsum board ceiling points 3 kinds of height, the first is 12 meters below, the second is 12-40 meters, the third is more than 40 meters. 3 kinds of high specifications for the construction requirements are not the same, the minimum is 12 meters below the light steel keel gypsum board ceiling The above is the light steel keel gypsum board ceiling of the two "lowest" if you need the lowest price, then the quality of protection is not.

- Q: I have a suspended ceiling that is 2' x 4'- the guy at Lowe's told me I can use the USG Lace 12 x 12 tiles to interlock to have 8 of them fit in a grid...is this actually possible? Everything I have seen online says that those are to staple or glue up- not to be placed in a 2' x 4' grid.

- I wouldn t think you could either. I would think that middle seam would sag after awhile,. Go with your gut and don t ... GL

- Q: My home is over 100 years old. I don't know when the ceiling was put up but it's been painted over a few times I'm sure. It looks like a tiled drop ceiling but I haven't seen any signs of a grid or any type of suspension. The ceiling is about 6 inches lower than it is in the adjoining rooms which are plaster ceilings. Many tiles feel nice and sturdy, but a few are almost paper thin and now have finger sized holes from where I pushed on them. I'm okay to leave as is. I don't want to get into pulling the whole ceiling down. But is there any other way to repair this? It isn't as easy as just swapping out the broken tiles with new.

- These probably do have suspension. I would just leave them the heck alone.

Send your message to us

Slimline Ceiling Grid Hot Sale Flat Groove Main Tee H38

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords