Bonroy Hooks for Drop Ceiling Grid Suspension Ceiling Tee

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized s

teel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic

cold roll forming and punching machineries guarantee the high precision.

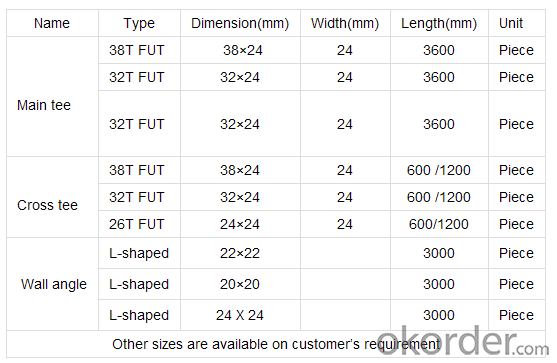

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized s

teel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic

cold roll forming and punching machineries guarantee the high precision.

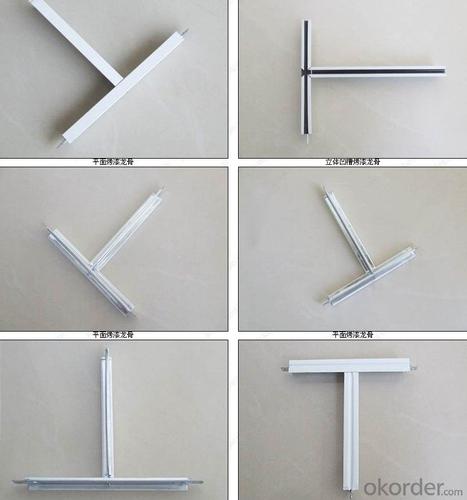

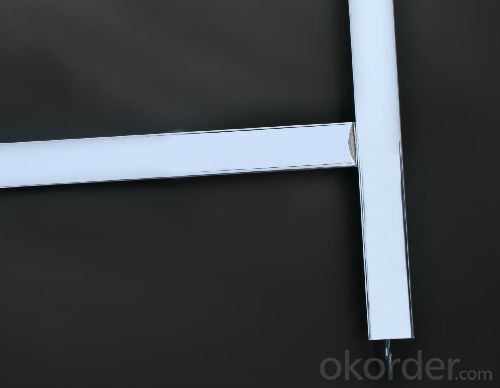

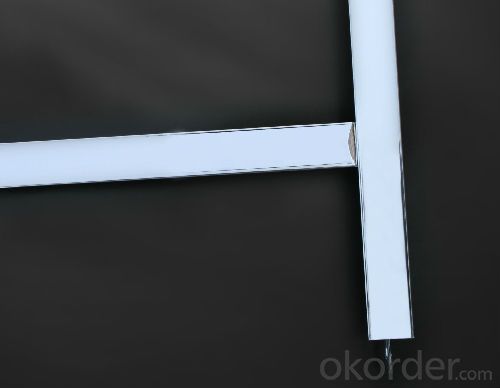

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

- Q: Construction Process of Light Steel Longguard Paving

- Installation process 1, operating conditions Light steel keel gypsum board ceiling installation of the operating conditions with the "wooden ceiling." 2, material preparation According to the design requirements, choose the appropriate U-shaped keel series, and according to the actual plane size prepared keel main parts and accessories. Cover panel varieties, specifications should meet the design requirements. 3, equipment to prepare Light steel keel gypsum board installation and construction of the machine with the "light steel keel gypsum board partition wall." 4, operating procedures Spinning line → fixed boom → installation of the big keel → by the elevation of the adjustment of the big keel → large keel bottom of the ball line (pull line) → fixed, small keel → installation of plaster board → gypsum plaster surface → clean The

- Q: T-type light steel keel tb24 * 38 what does it mean

- T-type is not on the person, the width of 24mm, height 38mm is the T-type main keel

- Q: I want to finish my garage. I can handle the walls and floor, but I can't seem to get any help for the ceiling. I went to my local Home Depot and talked to two different people. They sell the stuff, but don't have a clue as to what I would need. The room will be 14' x 24'. Any help would be a appreciated.PS: My zip code is 02816, if that helps.

- Home Depot lists a 400 sq ft drop ceiling grid installation kit for $14.38. They also list 2' x 4' ceiling panels for $4.11 each. I could not tell it the grid kit included the actual grid, or just hardware. Your room is 336 sq ft.

- Q: Light steel keel main keel, vice keel spacing generally how much

- The main keel and pay keel ceiling is this: the main keel and the main keel parallel row, the spacing of 1200mm,

- Q: Why home decoration ceiling with wooden keel and tooling ceiling with light steel keel

- Now basically home improvement with light steel keel, wood keel for a long time tide easily deformed.

- Q: Tooling, specifications have no provisions Light steel keel ceiling to brush fire paint?

- Do not use light steel is the thickness of 0.5 1.0 galvanized steel strip

- Q: Material u-type 50 series light steel keel in the main keel specifications is how much

- Simply talk to you about the connection between the keels: the boom with a bolt bolts fixed on the floor, with T-type keel hanging pieces connected T-shaped main keel, T-keel for long, in its interface with T-keel connections fixed, between the keel and the main keel is connected between the plug, you can not accessories. If the ceiling has an additional load or a large area of the ceiling, you need U-bearing keel, that is, after the installation of the boom, first with U-shaped keel (main keel) hanging pieces will U-shaped main keel and boom connection, T-type keel pendant connects the T-shaped longitudinal keel with the U-shaped main keel ... 1, T-type keel hanging pieces: for the T-type main keel and boom connection. Applicable only to non-loaded keel without additional load of the ceiling. 2, T-type keel connection: for the vertical T-keel that is the main keel connection. 3, U-type keel hanging pieces: for connecting the carrying keel (main keel) and boom. 4, T-type keel pendant: for U-type light steel keel and T-type longitudinal keel connection. 5, U-shaped main keel connection: for the U-type carrying keel of the long.

- Q: 3 meters wide and 6 meters high light steel keel wall how to do? 24 wall

- Mainly a high degree of problem, Steel keel

- Q: Home decoration the same shape of the ceiling, grass-roots keel or light steel keel prices high?

- If there are fire requirements, wood keel according to the standard two fire retardant coating, the cost may be higher than the light steel keel, and vice versa is low.

- Q: Light steel keel double gypsum board ceiling price is how much?

- I only know that home improvement, a little more than two hundred or so a flat, the general one hundred and fifty six bar. Tooling even cheaper, but the material certainly no home improvement. This is the price of regular companies

Send your message to us

Bonroy Hooks for Drop Ceiling Grid Suspension Ceiling Tee

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords