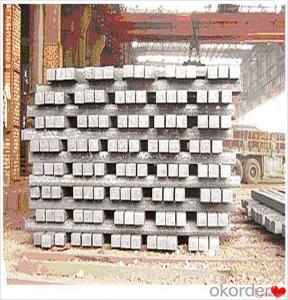

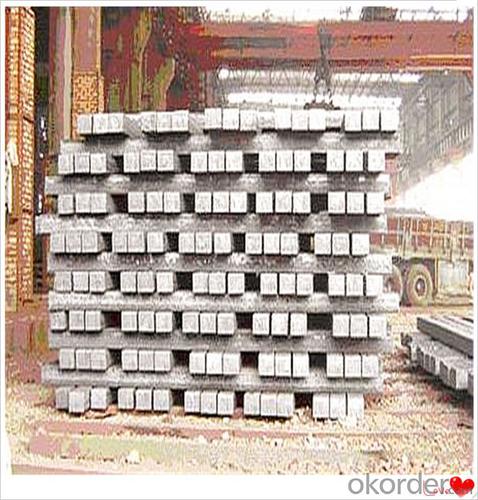

Converter Continuous Square Steel Billet 3SP 5SP 20MnSi Hot Selling

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Converter Continuous Square Steel Billet 3SP 5SP 20MnSi Hot Selling

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

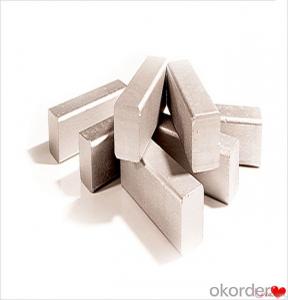

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different types of steel billet handling equipment?

- Some different types of steel billet handling equipment include overhead cranes, forklifts, conveyors, and magnetic lifting devices.

- Q: How are steel billets used in the manufacturing of telecommunications equipment?

- Steel billets are used in the manufacturing of telecommunications equipment as they serve as raw material for various components such as brackets, frames, and enclosures. These billets are shaped and machined into precise forms to provide structural support and protection for sensitive electronic components within telecommunications devices. Additionally, steel billets may also be used in the production of antenna towers and infrastructure, ensuring stability and durability in the telecommunications industry.

- Q: What are the different grades of steel used for producing billets?

- The different grades of steel used for producing billets vary depending on the specific requirements and applications. Some common grades include mild steel, low carbon steel, medium carbon steel, high carbon steel, alloy steel, and stainless steel. Each grade offers different mechanical properties, such as strength, durability, and corrosion resistance, to meet the desired characteristics for the final product.

- Q: How are steel billets used in the production of construction parts?

- Steel billets are an important raw material in the production of construction parts. They are essentially semi-finished steel products that are cast into square or rectangular shapes. These billets are then further processed and transformed into various construction components like beams, columns, rods, and bars. The first step in utilizing steel billets is heating them in a furnace to a temperature that allows for easy deformation and shaping. Once the billets reach the desired temperature, they are passed through a series of rolling mills, where they undergo hot rolling. This process involves repeatedly passing the billets through multiple pairs of rollers to gradually reduce their size and shape them into the required form, such as beams or rods. Hot rolling not only helps to shape the billets but also improves their mechanical properties, such as strength, toughness, and ductility. The resulting steel products are then cut to the desired lengths and further processed, if necessary, to meet specific construction requirements. These steel components made from billets are widely used in construction projects. For instance, beams made from steel billets are commonly used to provide structural support in buildings and bridges. They offer superior strength and load-bearing capacity, making them ideal for withstanding heavy loads and ensuring the overall stability of the structure. Steel rods and bars, on the other hand, are widely used in reinforced concrete construction. These components are embedded within the concrete to increase its tensile strength and prevent cracks from forming. They are essential in the construction of foundations, slabs, walls, and other structural elements that require added reinforcement. In summary, steel billets play a crucial role in the production of construction parts by serving as the starting point for the manufacturing process. Through hot rolling and subsequent processing, these billets are transformed into various steel components that are used to provide structural support, reinforcement, and durability in construction projects.

- Q: How are steel billets measured?

- Steel billets are typically measured using various instruments such as calipers, micrometers, or laser measurement systems to accurately determine their dimensions, including length, width, and height. These measurements are crucial for ensuring quality control and meeting specific industry standards.

- Q: What are the potential applications of steel billets in the textile industry?

- The textile industry can benefit from the wide range of potential applications offered by steel billets. One major area where steel billets prove useful is in manufacturing textile machinery components. Gears, shafts, and frames, crucial for the smooth functioning of textile machines, can be produced using steel billets. These components require high strength and durability, which steel billets provide to withstand the demanding operational conditions in the textile industry. Another application of steel billets in the textile industry is the production of molds and dies. By machining steel billets into intricate shapes, molds and dies can be created for fabricating textile products. Injection molding and extrusion processes, commonly used in textile manufacturing, rely on these molds and dies. Steel billets offer dimensional stability and resistance to wear and tear, making them ideal for producing long-lasting molds and dies. Moreover, steel billets can be employed in constructing textile production facilities. Steel, being versatile and strong, can be easily shaped and welded, making it suitable for building textile industry infrastructure. Steel billets can be used to fabricate support structures, frames, and beams for textile factories. These structures provide stability and strength to the buildings, ensuring the safe and efficient operation of textile production processes. Additionally, steel billets find applications in the packaging of textile products. Steel drums and containers, manufactured using steel billets, are commonly used for storing and transporting textiles. Steel drums offer excellent durability, protection against external factors, and resistance to damage during handling and transportation. In summary, the potential applications of steel billets in the textile industry are diverse and encompass various aspects of textile manufacturing, including machinery production, mold and die fabrication, construction, and packaging. Utilizing steel billets in these applications contributes to the efficiency, reliability, and quality of textile production processes.

- Q: How are steel billets used in the production of mining conveyors?

- Steel billets are used in the production of mining conveyors as they serve as the raw material for manufacturing various components such as frames, supports, and conveyor belts. These billets are heated, shaped, and machined to create the required parts that are strong, durable, and capable of withstanding the harsh conditions of the mining environment.

- Q: How do steel billets contribute to the manufacturing of construction machinery?

- Steel billets play a crucial role in the manufacturing of construction machinery. These cylindrical or square bars of steel are the primary raw material used in the production of various components and parts for construction machinery. Firstly, steel billets are used to create the structural frame of construction machinery. The high strength and durability of steel make it an ideal material for ensuring the structural integrity of heavy machinery. Steel billets are shaped and welded together to form the sturdy frame, providing the necessary support and stability to the equipment. Additionally, steel billets are used to manufacture critical components such as gears, shafts, and axles. These components require high tensile strength and resistance to wear and tear, which can be achieved using steel billets. By machining, forging, or casting steel billets into the desired shape, these components can withstand the heavy loads and harsh operating conditions in the construction industry. Moreover, steel billets are used to produce buckets, blades, and cutting edges for construction machinery. These components are subjected to extreme forces and abrasion during excavation, grading, and other construction activities. Steel billets, with their excellent hardness and toughness, ensure that these components can withstand the demanding conditions and perform effectively. Furthermore, steel billets are essential in the production of hydraulic cylinders and pistons. These components are responsible for generating the force required for lifting, pushing, and pulling heavy loads in construction machinery. Steel billets are machined and shaped to create the cylinder bodies and pistons, ensuring the necessary strength and precision for efficient hydraulic operations. In summary, steel billets are indispensable in the manufacturing of construction machinery. They provide the strength, durability, and wear resistance required for the various components and parts of construction equipment. Steel billets contribute to the overall performance and reliability of construction machinery, ensuring that they can withstand the demanding conditions and heavy workloads encountered in the construction industry.

- Q: How are steel billets used in the manufacturing of industrial tools?

- Steel billets are an essential raw material in the manufacturing of industrial tools. These billets, which are solid blocks of steel, serve as the foundation for creating various types of tools used in industries such as construction, automotive, and manufacturing. The first step in using steel billets for tool manufacturing is to heat them to a specific temperature. This process, known as forging, makes the steel more malleable and easier to work with. Once heated, the billets are then shaped and formed into the desired tool design using specialized machinery like power hammers and presses. The shaping process involves applying intense pressure to the heated billet, which transforms it into the desired tool shape. This can be a chisel, wrench, hammer head, or any other tool needed for specific industrial applications. The precise shaping ensures that the tool will have the necessary strength, durability, and functionality required for its intended use. After the initial shaping is complete, the tool is further refined and finished through processes like machining, grinding, and heat treatment. These additional steps help enhance the tool's performance and ensure its longevity. Machining removes any excess material and creates the necessary holes, threads, or other features required for the tool's functionality. Grinding provides a smooth surface finish and precise dimensions. Heat treatment is another critical process that involves subjecting the tool to controlled heating and cooling cycles. This treatment alters the steel's molecular structure, enhancing its hardness, strength, and toughness. Different heat treatment techniques like quenching and tempering are employed depending on the specific tool requirements. Once the tool has been shaped, machined, ground, and heat-treated, it undergoes a series of quality checks and inspections to ensure it meets the necessary specifications and standards. These checks include dimensional measurements, visual inspections, and functional tests to ensure that the tool is fit for its intended purpose. In summary, steel billets are integral to the manufacturing of industrial tools as they provide the base material that is shaped, machined, heat-treated, and refined to create durable and high-performing tools. The versatility and strength of steel make it an ideal choice for producing a wide range of tools used in various industries, contributing to their efficiency, productivity, and overall success.

- Q: How do steel billets contribute to the sustainability of construction projects?

- Steel billets contribute to the sustainability of construction projects in several ways. Firstly, steel is a highly durable and long-lasting material, ensuring that structures built with steel billets have a longer lifespan and require less maintenance and repairs over time. This longevity reduces the need for frequent reconstruction, saving resources and minimizing waste. Additionally, steel is a recyclable material, meaning that steel billets can be reused or repurposed at the end of their life cycle, reducing the demand for new steel production and lowering the environmental impact. Lastly, steel's strength-to-weight ratio allows for lighter and more efficient designs, resulting in reduced material consumption and energy usage during construction. Overall, the use of steel billets in construction projects promotes sustainability by enhancing durability, facilitating recycling, and optimizing resource efficiency.

Send your message to us

Converter Continuous Square Steel Billet 3SP 5SP 20MnSi Hot Selling

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords