Steel Billets 3sp 3SP 5SP 20MnSi Brand New Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billets 3sp 3SP 5SP 20MnSi Brand New Steel Billet

Description

Reference Price:$260/ton Mn 0.3%-0.6%

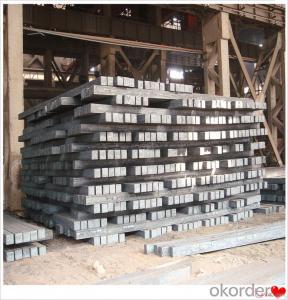

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

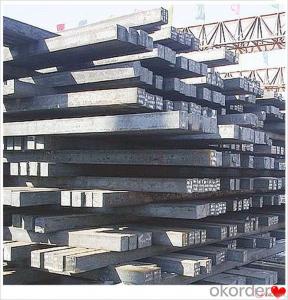

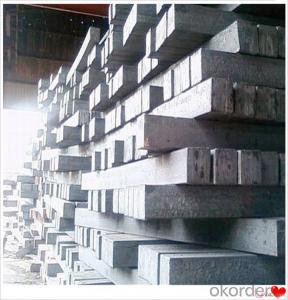

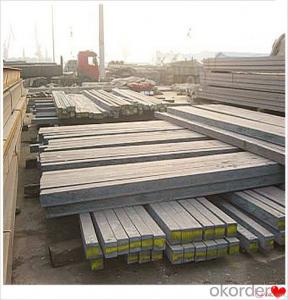

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the manufacturing of telecommunications equipment?

- Telecommunications equipment manufacturing relies heavily on steel billets, which serve as a crucial component. These billets act as the raw material that undergoes shaping and transformation to create various components used in telecommunications infrastructure. Primarily, steel billets are used in the production of towers and masts, providing the necessary support for antennas and other transmitting and receiving equipment. To ensure strength and stability, the billets are melted and then forged or rolled into the desired shape, forming the structural members of these towers. Moreover, steel billets are also essential in the manufacturing of cable trays and cable management systems. These components play a crucial role in organizing and protecting the extensive network of cables used in telecommunications systems. By processing and fabricating the billets into cable trays, brackets, and supports, a robust and durable solution is provided for managing the complex web of cables. Furthermore, steel billets find application in the production of enclosures and cabinets that house sensitive telecommunications equipment. These enclosures safeguard the equipment from environmental factors like dust, moisture, and temperature fluctuations. By molding and shaping the steel billets into the desired size and design, a sturdy and secure enclosure is achieved. In conclusion, the role of steel billets in telecommunications equipment manufacturing cannot be overstated. Whether it is for towers and masts, cable trays, or enclosures, these billets lay the foundation and ensure the structural integrity necessary for the reliable operation of telecommunications infrastructure.

- Q: What are the main types of defects found in steel billets?

- Steel billets can suffer from a range of defects, including surface defects, internal defects, and segregations. Surface defects refer to any abnormalities, cracks, or discontinuities that can be found on the outer surface of the steel billet. These defects encompass scale, scratches, pits, and surface cracks. They are typically caused by mishandling during transportation or storage, improper handling during manufacturing, or insufficient surface cleaning. Internal defects are flaws or imperfections that exist within the inner structure of the steel billet. These defects include inclusions, cavities, blowholes, porosity, and non-metallic inclusions. They can be a result of improper melting and casting processes, incorrect cooling and solidification, or the presence of impurities in the steel. Segregations involve the uneven distribution of elements or impurities within the steel billet. As a consequence, certain sections of the billet may possess different chemical compositions or mechanical properties. Inadequate mixing during the melting process, improper pouring and solidification, or the presence of impurities in the raw materials can cause segregations. To ensure the quality and integrity of steel billets, it is essential to detect and rectify these defects. Various non-destructive testing techniques, such as visual inspection, ultrasonic testing, magnetic particle testing, and eddy current testing, are employed to identify and characterize these defects. Once identified, appropriate measures, including grinding, machining, or heat treatment, can be implemented to eliminate or mitigate the defects.

- Q: How are steel billets used in the manufacturing of industrial pumps?

- Steel billets are used in the manufacturing of industrial pumps as a starting material for the production of various pump components. These billets are typically made of high-quality steel and serve as the raw material for forging or casting processes. Firstly, steel billets are used in the production of pump casings. The billets are shaped into the desired form, either by forging or casting, to create the outer shell of the pump. This casing provides structural integrity and contains the fluid being pumped. Additionally, steel billets are utilized in the manufacturing of impellers, which are vital components of industrial pumps. Impellers are responsible for generating the necessary force to move the fluid through the pump. The billets are machined, shaped, and polished to form the intricate design of the impeller, ensuring optimal fluid flow and efficiency. Furthermore, steel billets are used for manufacturing shafts and other critical components of the pump. These components require high strength and durability to withstand the demanding conditions of industrial applications. By using steel billets, manufacturers can ensure the necessary mechanical properties are met, such as resistance to corrosion, wear, and high temperatures. In summary, steel billets play a crucial role in the manufacturing of industrial pumps. They serve as the starting material for various pump components, including casings, impellers, shafts, and more. By using high-quality steel billets, manufacturers can produce durable and efficient pumps that meet the demanding requirements of industrial applications.

- Q: What is the average cost of transporting steel billets?

- The average cost of transporting steel billets can vary depending on various factors such as distance, mode of transportation (road, rail, sea, or air), quantity, and current market conditions. It is advisable to consult with logistics providers or freight companies to obtain accurate and up-to-date pricing information.

- Q: How are steel billets used in the production of mining conveyors?

- The production of mining conveyors heavily relies on steel billets, which are essential for creating sturdy and durable components. Mining conveyors are responsible for transporting bulk materials like coal, ore, and gravel across long distances. To withstand the harsh conditions of a mining environment, these conveyors require robustness and durability. Conveyor rollers, crucial for the conveyor system's functionality, are manufactured using steel billets as the raw material. These rollers provide support and guidance to the conveyor belt. Initially, the steel billets undergo a heating process, which enhances their malleability, making shaping easier. Once heated, they are rolled into desired shapes to form the conveyor rollers. By incorporating steel billets into the production of mining conveyors, the resulting rollers possess excellent strength and resistance to wear and tear. The steel's properties, including toughness and hardness, make it highly suitable for enduring heavy loads and abrasive materials. Moreover, steel billets offer customization options to cater to specific requirements. Each mining operation may have unique needs in terms of conveyor dimensions, load capacities, and environmental conditions. With the use of steel billets, manufacturers can produce conveyor rollers of various sizes and specifications, ensuring a tailored fit for each mining operation. In conclusion, steel billets play a vital role in the production of mining conveyors as they serve as the primary material for manufacturing conveyor rollers. These rollers are indispensable for supporting and guiding the conveyor belt, enabling efficient and reliable transportation of bulk materials in the mining industry. By utilizing steel billets, the resulting conveyor rollers are strong, durable, and capable of withstanding the harsh conditions prevalent in the mining sector.

- Q: How are steel billets used in the production of automotive frames?

- Steel billets are used in the production of automotive frames as a primary raw material. Billets are essentially long, rectangular-shaped pieces of steel that are heated and then formed into specific shapes through various manufacturing processes. In the case of automotive frames, these billets are typically heated and then passed through a series of dies and rollers to form the desired shape and dimensions. Once the billets are formed into the appropriate shape, they are further processed through cutting, bending, and welding techniques to create the intricate and sturdy structure of an automotive frame. The use of steel billets in the production of automotive frames is preferred due to the high strength and durability properties of steel, which are crucial for ensuring the safety and structural integrity of the vehicles. Moreover, steel billets offer excellent formability and machinability, allowing manufacturers to create complex frame designs that meet the specific requirements of different vehicle models. Additionally, steel is a cost-effective material, making it a popular choice for mass production in the automotive industry. Overall, steel billets play a vital role in the production of automotive frames by providing a strong and reliable foundation for the vehicle's structure. The use of these raw materials, along with advanced manufacturing techniques, ensures that automotive frames are able to withstand various forces and impacts, ultimately contributing to the overall safety and performance of the vehicles.

- Q: How are the surface defects of steel billets repaired?

- The surface defects of steel billets are repaired through a process called grinding or machining. This involves removing the defective areas by using specialized tools and techniques to smoothen out the surface and make it suitable for further processing or use in various industries.

- Q: What is the size range of steel billets?

- The size range of steel billets can vary depending on the specific requirements of the industry or application. However, in general, steel billets are typically produced in square or rectangular shapes, with dimensions ranging from 100mm to 200mm in width and height, and lengths ranging from 3 to 12 meters. These dimensions can be customized based on the intended use of the billets, such as for forging, rolling, or further processing into finished steel products.

- Q: Can steel billets be used for making hand tools?

- Yes, steel billets can be used for making hand tools. Steel billets are essentially semi-finished steel products that are typically used for further processing and shaping into different forms. Hand tools such as wrenches, pliers, hammers, screwdrivers, and many others can be manufactured from steel billets. Steel is a popular choice for hand tool manufacturing due to its strength, durability, and resistance to wear and tear. Steel billets can be forged, machined, or heat-treated to create the desired shape, size, and hardness required for hand tools. The versatility of steel allows it to be easily molded into various tool designs, providing the necessary strength and functionality. Furthermore, steel hand tools offer several advantages over tools made from other materials. Steel's high tensile strength ensures that the tools can withstand high levels of force and pressure without breaking or deforming. Its resistance to corrosion and rusting makes steel tools suitable for both indoor and outdoor use, even in harsh environments. In conclusion, steel billets can indeed be used for making hand tools. The strength, durability, and versatility of steel make it an ideal material for manufacturing a wide range of hand tools that can withstand heavy usage and provide long-lasting performance.

- Q: Billet market trend

- 1, domestic crude steel production remains highAlthough the recent domestic steel market has been relatively low, and the loss of steel mills win less, but this does not seem to affect the enthusiasm of steel production. According to the China Steel Association statistics show that: in early April, the daily output of crude steel in key enterprises in China was 1 million 697 thousand and 300 tons, and the average daily output of crude steel in China was estimated at 2 million 123 thousand and 900 tons. And in mid April, crude steel daily output of ten days, although there has been a drop back, but still at a high level. According to statistics, in mid April, the average daily output of crude steel in key enterprises nationwide was 1 million 689 thousand and 100 tons, and the average daily output of crude steel in China was estimated at 2 million 115 thousand and 800 tons. Such a large production and sluggish demand in stark contrast, which is a drag on steel prices down one of the important factors.

Send your message to us

Steel Billets 3sp 3SP 5SP 20MnSi Brand New Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords