Buy Stainless Steel

Buy Stainless Steel Related Searches

Stainless Steel For Sale Stainless Steel Supply Near Me Cheap Stainless Steel Stainless Steel Shop Near Me Best Stainless Steel Price Stainless Steel Stainless Steel Supply Seal Stainless Steel Stainless Steel Wholesale Custom Stainless Steel Stainless Steel Plate For Sale Stainless Steel Price Stainless Steel Supplier Stainless Steel Jewelery Stainless Steel Storage Price For Stainless Steel Stainless Steel Hardware Paint Stainless Steel Restore Stainless Steel Stainless Steel Jewellery Stainless Steel Prices Recycle Stainless Steel Stainless Steel Sets Shop Vacuum Stainless Steel Stainless Steel Jewlery Color Stainless Steel Stainless Steel Near Me Stainless Steel Outlets Drill Stainless Steel Stainless Steel ProductsBuy Stainless Steel Supplier & Manufacturer from China

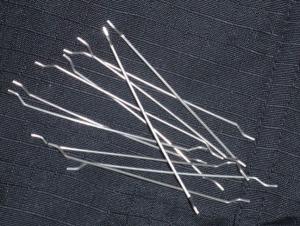

Buy Stainless Steel is a popular choice for various products due to its durability, corrosion resistance, and aesthetic appeal. It is widely used in the manufacturing of kitchen appliances, cutlery, architectural structures, and industrial equipment, among other applications. This versatile material is known for its ability to withstand harsh conditions and maintain its appearance over time, making it a preferred option in both residential and commercial settings.Stainless steel products are utilized in a broad range of scenarios, from everyday household items to complex industrial machinery. Its resistance to staining and rusting, along with its ease of cleaning, makes it an ideal material for use in food processing and medical equipment. Additionally, its strength and low maintenance requirements make it a popular choice for construction and infrastructure projects. Whether it's for decorative purposes or functional applications, stainless steel offers a reliable and long-lasting solution.

Okorder.com is a reputable wholesale supplier of Buy Stainless Steel products, boasting a vast inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that their stainless steel offerings meet the highest industry standards. By providing a comprehensive selection of stainless steel products, Okorder.com has established itself as a go-to source for businesses and individuals alike who require reliable and high-quality materials for their projects.

Hot Products