5ps Steel Billets 3SP 5SP 20MnSi Professional Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

5ps Steel Billets 3SP 5SP 20MnSi Professional Steel Billet

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

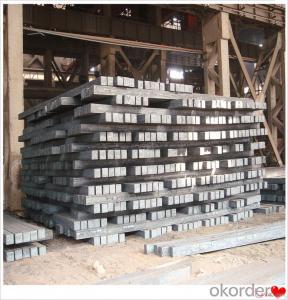

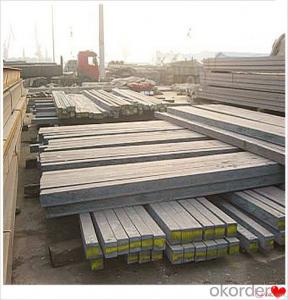

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: Are steel billets used in the manufacturing of construction machinery?

- Yes, steel billets are commonly used in the manufacturing of construction machinery. Steel billets are semi-finished products that are used as raw materials in various industries, including construction machinery manufacturing. These billets are typically made from molten steel that is cast into a solid form and then further processed to shape and size. Due to their high strength, durability, and versatility, steel billets are ideal for constructing heavy-duty components and structures in construction machinery. They can be used to manufacture various parts such as chassis, frames, buckets, booms, and arms, among others. The use of steel billets ensures that construction machinery is capable of withstanding the demanding conditions and heavy loads commonly encountered in construction projects.

- Q: What are the different methods of steel billet cooling?

- There are several methods of steel billet cooling, including air cooling, water cooling, and accelerated cooling.

- Q: How are steel billets used in the manufacturing of tooling?

- Tooling manufacturing relies heavily on steel billets as a vital element. Tooling involves the creation and design of tools utilized across different industries for the purpose of cutting, shaping, or forming materials. Steel billets are semi-finished goods formed by casting molten steel and subsequently hot rolling them into diverse sizes and shapes. In tooling manufacturing, steel billets serve as the fundamental material from which tools are shaped. Typically, these billets are crafted from high-quality steel alloys known for their exceptional strength, durability, and resistance to wear. The presence of these traits is crucial in tooling applications as they guarantee the longevity and performance of the tools. Once steel billets are acquired, they undergo a series of processes to transform them into tooling components. The initial step entails heating the billets to a specific temperature, often exceeding the recrystallization temperature. This elevation in temperature renders the steel more malleable and easier to shape. This process is referred to as hot working. Subsequent to heating, the steel billets are shaped into the desired form using a variety of techniques including forging, extrusion, or rolling. These methods enable the steel to be molded into intricate shapes such as dies or molds, which are commonly employed in tooling applications. The shaping process ensures that the tooling components possess the requisite dimensions, surface finish, and structural integrity to effectively fulfill their intended purpose. Once the tooling components are shaped, they may undergo additional heat treatments to further enhance their mechanical properties. Processes such as tempering, annealing, or hardening are frequently employed to modify the steel's hardness, toughness, and resistance to wear. These treatments augment the lifespan of the tooling and enhance its performance in demanding manufacturing environments. In summary, steel billets play a vital role in tooling manufacturing by serving as the initial material for shaping tooling components. The utilization of high-quality steel in billets provides the necessary strength and durability required for tooling applications. Through the process of shaping, heat treating, and finishing these billets, manufacturers are able to create tooling that meets the specific requirements of diverse industries, enabling efficient and precise cutting, shaping, and forming of materials.

- Q: How do steel billets contribute to the infrastructure development?

- Steel billets are a crucial component in infrastructure development as they serve as the raw material for manufacturing various steel products used in construction. These billets are used to produce reinforcement bars, beams, columns, and other structural elements that provide strength and stability to buildings, bridges, roads, and other infrastructure projects. By providing a strong and durable foundation, steel billets contribute significantly to the overall safety and longevity of infrastructure, promoting sustainable development and economic growth.

- Q: What are the disadvantages of using steel billets?

- Some potential disadvantages of using steel billets include their high cost, the need for specialized equipment and processes to handle and shape them, and their relatively limited availability compared to other forms of steel. Additionally, steel billets can be susceptible to defects such as cracking or porosity, which may require additional quality control measures.

- Q: How are steel billets used in the production of automotive suspension components?

- Due to their strength, durability, and malleability, steel billets play a crucial role in manufacturing automotive suspension components. Billets, which are semi-finished steel products, are shaped into specific forms like bars or rods through a process called hot rolling. When it comes to automotive suspension components, the initial step involves heating the steel billets to a high temperature. Subsequently, they are passed through a series of rollers to achieve the desired shape, such as coil springs, shock absorber rods, or stabilizer bars. This hot rolling process refines the grain structure of the steel, resulting in improved mechanical properties. The utilization of steel billets in suspension components is vital because they provide the necessary strength and stiffness to withstand the various forces and loads faced during vehicle operation. For instance, coil springs bear the weight of the vehicle and ensure a comfortable ride by absorbing impacts and vibrations. Steel billets are preferred for automotive suspension components due to their high tensile strength, which enables them to endure heavy loads and maintain their shape over extended periods. Moreover, the malleability of steel allows for easy forming and shaping into intricate geometries, ensuring precise fit and functionality within the suspension system. Furthermore, steel billets offer excellent fatigue resistance, which is crucial for suspension components as they experience repetitive loading and unloading throughout the vehicle's lifespan. This fatigue resistance helps prevent failures and ensures a suspension system that is long-lasting and dependable. In conclusion, incorporating steel billets into the production of automotive suspension components is essential for achieving the necessary strength, durability, and performance required for safe and comfortable vehicle operation.

- Q: What are the potential applications of steel billets in the mining aftermarket?

- Steel billets possess a wide range of potential applications within the mining aftermarket. The manufacturing of heavy machinery and equipment utilized in mining operations represents one of the primary uses for steel billets. These components, including gears, shafts, and cylinders, necessitate high strength and durability to withstand the harsh conditions inherent in mining activities. Moreover, steel billets can also be employed in the creation of wear-resistant parts for mining equipment, such as cutting edges, buckets, and liners. Given the intense wear and tear endured by these parts, the use of steel billets guarantees their longevity and dependability. Additionally, steel billets find use in the construction of mine support structures, such as beams, columns, and frames. These structures play a crucial role in ensuring the stability and safety of mining operations, and steel billets provide the requisite strength and load-bearing capacity for their construction. Furthermore, steel billets can be utilized in the production of tools and accessories essential for mining activities. Drill bits, hammers, and chisels, for instance, demand high strength and toughness to effectively penetrate hard rock formations. Steel billets serve as the ideal material for fabricating these tools. In summary, the potential applications of steel billets within the mining aftermarket are extensive and encompass various aspects of mining operations. Ranging from the manufacturing of heavy machinery and equipment to the production of wear-resistant parts and mine support structures, steel billets provide the necessary strength, durability, and reliability required to optimize mining processes.

- Q: What are the main factors affecting the machinability of steel billets?

- Several key factors influence the machinability of steel billets, which refers to the ease with which they can be cut and shaped by machining processes. These factors encompass the composition of the steel, its microstructure, the presence of impurities or inclusions, and the mechanical properties of the material. The machinability of steel is significantly impacted by its composition. Elements like carbon, manganese, sulfur, and phosphorus play a crucial role in determining the cutting performance. For example, a higher carbon content can increase hardness, thereby making the steel more challenging to machine. Conversely, manganese can enhance machinability by promoting the formation of a favorable microstructure. The microstructure of the steel, influenced by factors such as heat treatment and alloying elements, also affects machinability. Fine-grained steels with a homogeneous microstructure are generally easier to machine compared to coarse-grained ones. Additionally, the inclusion of alloying elements like chromium or molybdenum can enhance machinability by increasing the material's hardness and wear resistance. Machinability can be negatively affected by impurities or inclusions present in the steel, such as non-metallic particles or oxides. These impurities can result in tool wear, surface defects, and inadequate chip formation during machining. Therefore, minimizing the level of impurities in the steel through meticulous production and refining processes is crucial. Moreover, the mechanical properties of the steel, including hardness, strength, and ductility, impact machinability. High-strength steels tend to be more challenging to machine due to their increased hardness, necessitating greater cutting force. Ductility also plays a vital role as it affects the steel's ability to form chips during machining. Striking a balance between hardness and ductility is desirable for optimal machinability. In conclusion, the machinability of steel billets is influenced by various factors encompassing composition, microstructure, impurities, and mechanical properties. It is imperative to comprehend and control these factors to ensure efficient and effective machining processes.

- Q: How do steel billets contribute to the manufacturing of furniture and fixtures?

- Due to their unique properties, steel billets are indispensable in the production of furniture and fixtures. The strength and stability they offer are essential for constructing these items, providing a solid framework that can support their weight and load-bearing capacity. This ensures that the furniture and fixtures will remain functional for an extended period of time. Additionally, the malleability of steel billets allows for the creation of intricate designs and shapes, enhancing the aesthetic appeal of furniture and fixtures. Manufacturers can take advantage of this flexibility to produce a wide range of styles and patterns that cater to different consumer preferences and interior design themes. Moreover, steel billets can be easily welded, making them perfect for joining various components together during the manufacturing process. This welding capability ensures a seamless and secure construction, ultimately improving the overall quality and durability of the furniture and fixtures. Furthermore, steel billets possess corrosion-resistant properties, making them suitable for indoor and outdoor furniture and fixtures alike. This resistance to rust and decay guarantees that these items can withstand harsh environmental conditions, preserving their appearance and structural integrity over time. In conclusion, the role of steel billets in the manufacturing of furniture and fixtures cannot be overstated. Their strength, malleability, weldability, and corrosion resistance contribute to the durability, design flexibility, and longevity of these items, making them a preferred choice for both manufacturers and consumers.

- Q: Does anyone know how much it costs to refine a ton of steel? What are the expenses involved?

- now the steel profits are not as good as before, a ton of net profit is about 100 yuan

Send your message to us

5ps Steel Billets 3SP 5SP 20MnSi Professional Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords