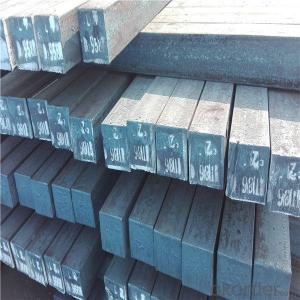

Hot rolled steel billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

After casting billet is ingot steel products. Mainly from the manufacturing process of billet can be divided into two kinds: die casting billet, slab and the die casting process has been basically eliminated. Mainly from the shape is divided into two kinds:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

use

The editor

Billet was rolled steel, after processing can be used for mechanical parts, forging parts, processing all kinds of steel, steel Q345B channel steel, wire rod is the role of the billet.

Steel billet is used in the production of semi-finished products, generally cannot be used directly for the society. Steel billets and steel are strictly divided into standard, cannot decide to whether the business enterprise of the final product, and according to unified standards to perform the whole society. Typically, billet and the steel is relatively easy to distinguish, but for some steel billet, and have the same specification and same steel purposes (such as rolling tube billet), whether can be used for other industries, whether through steel processing process, whether through a finished product rolling mill processing to distinguish. [1]

3 material

The editor

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The production process

Steel billet is produced by the method of through three processes:

It is through the steelmaking system of continuous casting equipment, directly by the molten steel pouring into billet;

The second is the steelmaking system in the production of steel ingot casting billet through system of steel rolling rolling equipment or processing of steel semi-finished products; Three is the steelmaking system production of steel ingot by forging the semi-finished product processing equipment. [1]

4 market movements

The editor

1, high domestic crude steel production

Although the domestic steel market has been weak in these days, and steel mills deficit to win more less, but it does not seem to affect the enthusiasm of steel production. According to figures from the cisa: early April, the domestic key enterprises crude steel output of 1.6973 million tons, the national forecasts crude steel output of 2.1239 million tons a day. And mid-april although ten-day monthly crude steel output has dropped, but still at a higher level. According to statistics, in the middle of April crude steel output was 1.6891 million tons a day national key enterprises, the national forecasts crude steel output of 2.1158 million tons a day. So much of the production and demand downturn in stark contrast, this also is a drag on one of the important factors of billet prices downward.

2, the billet demand has no obvious improvement

Although has entered the traditional peak season demand, steel billet actual demand situation there is no improvement, even weak parts in March, the market for manufacturer of may is more pessimistic. Currently, tangshan market view, the billet rolling operating at less than 80%, and the rolling factory procurement cautious, inventory control in the low post. Weaker terminal market, steel billet, the rose slightly, weakened purchasing immediately; And the price, demand is also no substantive improvement.

3, tangshan billet falling inventories

It is understood that in April tang shan area each big rolls billet stock began to decline, as of April 28, tangshan billet inventory around 1.25 million tons, than high roughly halved. But there is also a manufacturer said: some resources is made after converted to traders, actually is much larger than the inventory statistics, and 1.25 million tons of steel billet inventory is about 2.5 times in the same period last year.

In addition, China industry insight into network analysts believe the macroeconomic situation is weaker, the negative news is more steel and iron and steel industry the credit crisis will be adverse to the billet market outlook. But considering the steel mills had been losing money in production, make steel billet has certain defensive; And a small long vacation before five billet prices fell back quickly, it is likely to holiday makers to pull up some bedding.

Material standard

The editor

Range of thickness: 150-240 - mm + / - 5 mm width range: 880-1530 - mm + / - 20 mm

Length: 3700-10000 - mm + / - 500 - mm

Cross-sectional size: 64 * 64; 82 * 82; 98 * 98; 124 * 124; 120 * 150; 152 * 164; 152 * 170 mm

Length: 9000 mm

Section of tolerance: billet: 1.0 + / - 2.0-1.0 + / - 1.0 mm slab: width: + / - 2.0 mm thickness: + / - 3.0 mm

The length tolerance: + / - 200 mm

Section diagonal tolerance: 3.5-8.0 MM

Billet section size protrusions requirements: < 1242 mm, do not allow; > = 1242 mm, < = 2 mm 1242 mm, < = 3 mm

Beheading (shear) extension deformation: < 1242 mm billet: no control; The slab: < = 15 mm

Surface tilt: no more than billet section 0.1

Bending: every 1 m length is not more than 10 mm.

- Q: If the casting speed is not steady, what will happen to the billet?

- First of all, the probability of slag circle, dimple, crack and blowhole on the surface of the billet will increase, and the slag inclusion in the slag will increase, which will affect the internal and surface quality of the slab.

- Q: Can steel billets be used in the production of marine equipment?

- Yes, steel billets can be used in the production of marine equipment. Steel is known for its strength, durability, and corrosion resistance, making it a suitable material for marine applications. Steel billets, which are semi-finished products in the steel manufacturing process, can be further processed and transformed into various marine equipment components such as ship hulls, propeller shafts, rudders, and offshore structures. The high strength-to-weight ratio of steel makes it ideal for handling the demanding conditions encountered in marine environments, including exposure to saltwater, extreme temperatures, and mechanical stresses. Additionally, steel can be easily fabricated, welded, and machined, allowing for the customization and production of complex marine equipment designs. Overall, steel billets are a valuable raw material in the production of marine equipment due to their strength, durability, and suitability for marine applications.

- Q: How do steel billets contribute to the infrastructure development?

- Steel billets play a crucial role in the infrastructure development due to their versatility and strength. These solid blocks of steel are used as a raw material in the construction of buildings, bridges, and other infrastructure projects. One of the primary ways steel billets contribute to infrastructure development is through the production of reinforced concrete. Steel rebars, which are made from steel billets, are embedded within the concrete to provide additional strength and durability. This reinforcement helps to withstand the forces exerted on the structure, ensuring its long-term stability. Moreover, steel billets are also used in the manufacturing of structural steel sections such as beams, columns, and trusses. These components are essential for constructing various types of infrastructure, including high-rise buildings and bridges. The use of steel in these applications provides excellent load-bearing capacity, allowing for the construction of large and complex structures. Steel billets are also utilized in the production of pipes, which are vital for infrastructure systems like water supply, sewage, and gas pipelines. The strength and corrosion resistance of steel make it an ideal material for these applications, ensuring the integrity and longevity of the infrastructure network. Another significant contribution of steel billets to infrastructure development is in the manufacturing of heavy machinery and equipment used in construction projects. From cranes to excavators, steel billets are used to construct the frames and other structural components of these machines, ensuring their strength and reliability. In summary, steel billets contribute to infrastructure development by providing the necessary strength and durability for various construction applications. Whether it is reinforcing concrete, manufacturing structural components, or constructing heavy machinery, steel billets play a vital role in creating resilient and long-lasting infrastructure.

- Q: What are the different types of steel billet casting methods?

- There are several different methods used for steel billet casting, each with its own advantages and applications. The most commonly used methods include continuous casting, static casting, and centrifugal casting. 1. Continuous Casting: This is the most widely used method for steel billet casting. In this process, molten steel is poured into a water-cooled mold, where it solidifies into a continuous strand. The strand is then cut into desired lengths by a cutting machine. Continuous casting allows for high production rates and consistent quality, making it ideal for mass production of steel billets. 2. Static Casting: Also known as ingot casting, this method involves pouring molten steel into a stationary mold, where it solidifies into a solid billet. The mold is typically made of sand or metal, and the solidification process can be controlled to obtain desired properties. Static casting is often used for smaller production runs or when specific alloy compositions or shapes are required. 3. Centrifugal Casting: This method utilizes centrifugal force to distribute molten steel evenly within a rotating mold. As the mold spins, the molten steel is pushed towards the mold walls, resulting in a uniform casting with improved density and mechanical properties. Centrifugal casting is commonly used for large and complex billets, such as those used in pipe manufacturing or turbine components. These are the main methods used for steel billet casting; however, there may be variations or combinations of these methods depending on specific requirements or technological advancements.

- Q: What are the different methods of steel billet surface grinding?

- There are several methods of steel billet surface grinding, including abrasive grinding, belt grinding, and centerless grinding.

- Q: What is the role of steel billets in the production of sheet metal?

- Steel billets play a crucial role in the production of sheet metal as they are the primary raw material used to create thin, flat sheets of metal. These billets are heated, rolled, and shaped through a series of processes to transform them into sheet metal. The quality and composition of the billets directly impact the strength, durability, and overall characteristics of the final sheet metal product.

- Q: What is the global production capacity of steel billets?

- The global production capacity of steel billets is difficult to determine precisely as it constantly fluctuates due to various factors such as demand, market conditions, and technological advancements. However, it is estimated to be in the range of several hundred million metric tons annually.

- Q: Are steel billets recyclable?

- Yes, steel billets are recyclable.

- Q: How are steel billets used in the production of industrial pumps?

- Industrial pumps rely on steel billets as a vital ingredient in their manufacturing process. These billets serve as the primary material from which the different pump parts are created. To commence, the steel billets are initially heated to a specific temperature to render them pliable and more manageable. Following this, they are placed within a forging machine where they endure substantial pressure and are shaped into the desired form. This procedure, known as forging, allows the billets to be converted into diverse pump components, including impellers, casings, and shafts. Once the components have been forged, they undergo a sequence of machining operations to further refine their shape and dimensions. This encompasses milling, drilling, and grinding in order to achieve the necessary tolerances and surface finish. These operations are critical to ensure the correct fit and functionality of the pump parts. The steel billets employed in the production of industrial pumps are typically crafted from high-quality steel alloys that possess exceptional strength, durability, and resistance to corrosion and wear. This guarantees that the resulting pump components can endure the demanding operating conditions frequently encountered in industrial applications. Moreover, the use of steel billets enables the customization of pump parts to meet specific requirements. By altering the shape and dimensions of the billets, manufacturers can achieve different pump designs and sizes. This production flexibility allows manufacturers to cater to a broad array of pump applications across diverse industries. In conclusion, steel billets occupy a pivotal role in the production of industrial pumps. Through the process of forging, machining, and customization, these billets are transformed into top-notch pump components that offer superior performance and reliability in industrial environments.

- Q: What are the different surface treatments for improved corrosion resistance in steel billets?

- Steel billets can undergo different surface treatments to enhance their resistance to corrosion. These treatments aim to establish a protective barrier on the steel's surface, preventing corrosive agents from reaching the metal beneath. Some commonly used surface treatments for improved corrosion resistance in steel billets include: 1. Hot-dip galvanizing: Immersing the steel billets in molten zinc creates a galvanized coating, which is a zinc-iron alloy. This coating offers excellent corrosion resistance and prolongs the lifespan of the steel billets. 2. Electroplating: Through electroplating, a thin layer of metal such as zinc or nickel is applied to the steel billets using an electric current. This layer acts as a protective barrier against corrosion and provides an attractive finish. 3. Powder coating: By applying a dry powder mixture of resin and pigment to the steel billets and heating it, a durable and corrosion-resistant layer is formed. Powder coating is available in various colors and finishes. 4. Paint coatings: Applying corrosion-resistant paint to steel billets creates a protective barrier that hinders moisture and corrosive agents from reaching the steel. Multiple layers of paint can be added for enhanced durability and longevity. 5. Passivation: Passivation is a chemical process that eliminates free iron and contaminants from the steel billets' surface. This process prevents corrosion and encourages the formation of a protective oxide layer. Passivation is often combined with other surface treatments like electroplating or powder coating to enhance corrosion resistance. It is important to consider factors such as the billets' operating environment, desired lifespan, and cost considerations when choosing a surface treatment for improved corrosion resistance. A thorough evaluation of specific requirements and professional consultation are crucial in determining the most suitable treatment option.

Send your message to us

Hot rolled steel billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords