Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

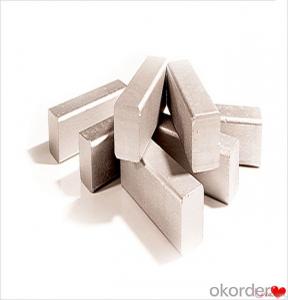

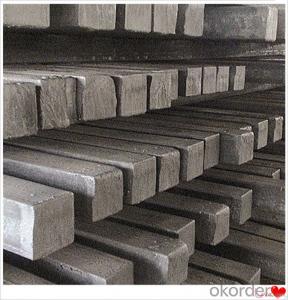

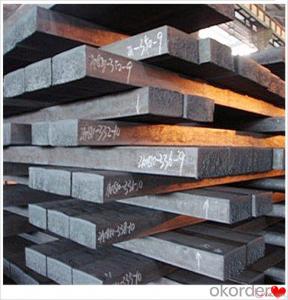

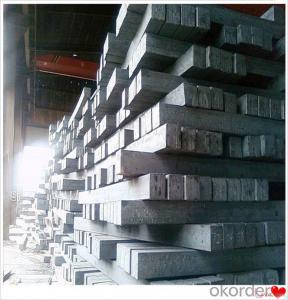

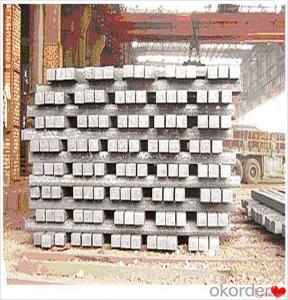

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the manufacturing of power generation equipment?

- Steel billets are an essential raw material in the manufacturing of power generation equipment. These billets are large, rectangular or square-shaped semi-finished steel products that are cast from molten steel and then hot rolled or forged into their final shape. In the context of power generation equipment, steel billets are primarily used in the construction of turbine components, such as turbine blades and rotors, as well as in the fabrication of generator casings and other structural parts. The high strength and durability of steel make it an ideal material for these critical components, as they need to withstand high temperatures, pressure, and rotational forces. The process begins with the selection of an appropriate grade of steel billet, which depends on the specific requirements of the power generation equipment. The billets are then heated to a suitable temperature and forged or hot rolled to shape them into the desired form. This process involves precise machining, cutting, and shaping techniques to achieve the required dimensions and surface finish. Once the turbine components and other parts are formed from the steel billets, they undergo further treatments such as heat treatment, surface coating, and machining to enhance their mechanical properties and ensure their compatibility with the power generation system. The final products are then assembled into the power generation equipment, which may include gas turbines, steam turbines, wind turbine components, or generator sets. Steel billets play a crucial role in the manufacturing of power generation equipment by providing the necessary strength, durability, and performance required for efficient and reliable operation. The quality and precision in the production of steel billets directly impact the overall performance and longevity of the power generation equipment, making them a vital component in the industry.

- Q: What are the different surface treatment options for steel billets?

- Some of the different surface treatment options for steel billets include pickling, shot blasting, galvanizing, painting, and powder coating.

- Q: Can steel billets be forged?

- Yes, steel billets can be forged. Forging is a common method used to shape metals into desired forms by applying compressive forces. Steel billets, which are semi-finished products in the form of rectangular bars, can undergo forging to transform them into various shapes such as bars, plates, or complex geometries. During the forging process, the steel billets are heated to a specific temperature to make them malleable, and then they are subjected to mechanical forces using hammers, presses, or other forging equipment. This enables the billets to be shaped and compressed, thereby improving their mechanical properties and imparting specific characteristics to meet desired requirements. Overall, forging steel billets is an important process in the production of various metal components and products.

- Q: What are the causes of internal cracks in continuous casting billet?

- The test according to the process of the sample for cooling, in order to study the effects of the three elements of the internal crack of continuous casting billet hot.

- Q: What are the main challenges in the recycling of steel billets?

- One of the main challenges in the recycling of steel billets is the presence of impurities and contaminants that need to be removed in order to produce high-quality recycled steel. Another challenge is the need for efficient sorting and separation techniques to properly categorize and process different types of steel billets. Additionally, the energy-intensive nature of the steel recycling process poses a challenge in terms of reducing carbon emissions and achieving sustainability goals.

- Q: Billet production process

- Billets are produced by three process methods:First, through the steelmaking system of continuous casting equipment, from the direct pouring of molten steel billet;

- Q: What is the role of steel billets in the production of railway wagons?

- Steel billets play a critical role in the production of railway wagons as they serve as the raw material for manufacturing various components, such as the wagon body, chassis, and structural elements. These billets are heated and shaped into desired forms through processes like rolling and forging, which enable the creation of strong and durable wagon parts. By providing the necessary strength and structural integrity, steel billets contribute to the overall safety, reliability, and longevity of railway wagons, ensuring they can withstand the demanding conditions and heavy loads encountered during their service on the railways.

- Q: How are steel billets used in the production of axles?

- Steel billets are used in the production of axles as a starting material. They are heated and shaped through forging or rolling processes to form the desired axle shape. This ensures the axle has the necessary strength and durability to support the weight and withstand the forces experienced during operation.

- Q: What are the potential applications of steel billets in the oil and gas sector?

- Steel billets have a wide range of potential applications in the oil and gas sector due to their excellent mechanical properties and durability. Here are some of the potential applications: 1. Drill pipes and casings: Steel billets can be used to manufacture drill pipes and casings, which are essential components in the drilling process. These pipes and casings need to withstand high pressure and extreme temperatures, and steel billets provide the necessary strength and toughness required for such demanding conditions. 2. Pipelines: Steel billets can be used to produce seamless or welded steel pipes for oil and gas pipelines. These pipes are used for the transportation of oil, gas, and other petroleum products over long distances. Steel billets ensure the durability and integrity of the pipelines, as they can withstand high pressure, corrosion, and impact. 3. Offshore structures: Steel billets are also used in the construction of offshore platforms, drilling rigs, and other structures used in the extraction and production of oil and gas from offshore reserves. These structures are exposed to harsh marine conditions, including saltwater, wind, and waves. Steel billets provide the necessary strength and corrosion resistance to withstand these challenging environments. 4. Pressure vessels and storage tanks: Steel billets can be utilized to manufacture pressure vessels and storage tanks used for the storage and transportation of oil, gas, and various chemicals. These vessels and tanks need to withstand high pressure and temperature variations without compromising safety. Steel billets provide the required strength and resistance against corrosion and leakage. 5. Equipment components: Steel billets are also used to fabricate various components and equipment used in the oil and gas sector, such as valves, flanges, fittings, and connectors. These components play a crucial role in the operation and maintenance of oil and gas facilities, and steel billets ensure their reliability and performance. Overall, the potential applications of steel billets in the oil and gas sector are vast and diverse, covering various stages of exploration, production, transportation, and storage. Their exceptional strength, durability, and resistance to extreme conditions make them an ideal material choice for critical applications in this industry.

- Q: What are the safety precautions when handling steel billets?

- To minimize the likelihood of accidents and injuries when dealing with steel billets, it is crucial to adhere to various safety measures. Firstly, it is of utmost importance to wear suitable personal protective equipment (PPE) such as safety goggles, steel-toed boots, gloves, and a hard hat. Before commencing the handling of steel billets, it is necessary to ensure that the work area is free from any obstructions or debris that could potentially cause trips or falls. Additionally, it is essential to stack and store the billets correctly to prevent unexpected falls or shifts. When it comes to lifting or moving steel billets, one should exercise caution regarding their weight and size. Utilizing appropriate lifting equipment like cranes, forklifts, or hoists is necessary to avoid strains or musculoskeletal injuries. It is crucial to always adhere to the weight limits and load capacities specified for the equipment being employed. To prevent slippage or falling, it is important to maintain a secure grip on the billets. One should avoid sharp edges or protruding parts that could result in cuts or puncture wounds. If required, the use of protective covers or padding can prevent contact with sharp or jagged edges. Proper communication plays a vital role in the handling of steel billets. It is imperative to establish clear communication among the workers involved in the process to prevent accidents or mishaps. Hand signals or radios can be employed to facilitate effective communication, especially in noisy environments. Regular inspection of the steel billets should be conducted before handling them to identify any defects or damage. Cracks, rust, or any other issues can compromise the structural integrity of the billets and increase the risk of accidents. If any defects are detected, they should be reported to a supervisor, and the appropriate procedures for handling or disposing of the billets should be followed. Lastly, it is crucial to always be aware of one's surroundings and the movements of other workers when handling steel billets. Standing or working in the swing radius of lifting equipment or near moving machinery should be avoided to prevent being struck or crushed. By adhering to these safety precautions, the risk of accidents and injuries during the handling of steel billets can be significantly reduced, thereby creating a safer work environment.

Send your message to us

Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords