Steel Billet steel Billet for Sale 3SP 5SP 20MnSi for Fireplace Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet steel Billet for Sale 3SP 5SP 20MnSi for Fireplace Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

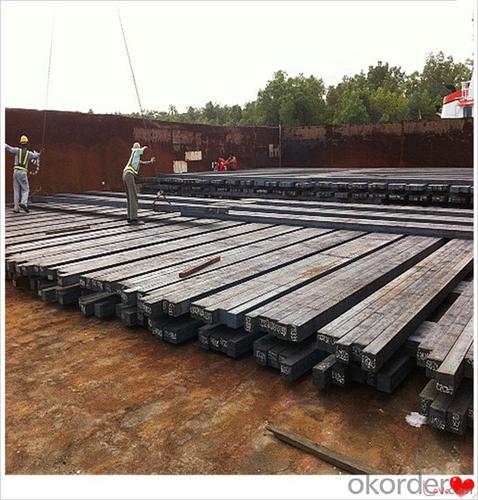

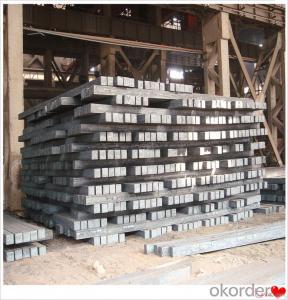

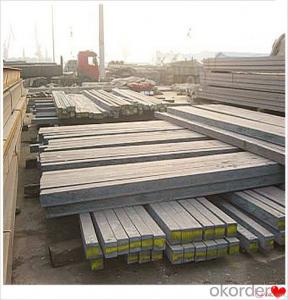

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets stored to prevent rusting?

- To prevent rusting, various measures are taken to store steel billets. Firstly, a dry and controlled environment with low humidity levels is typically utilized. This helps to minimize the presence of moisture, which is a primary catalyst for rust formation. Additionally, a protective layer such as oil or a rust inhibitor is often applied to the steel billets. This creates a barrier between the metal surface and the surrounding atmosphere, acting as a shield against moisture and oxygen. By preventing contact between these elements and the steel, rust formation is effectively hindered. Furthermore, to further reduce the risk of moisture absorption, steel billets are often stored off the ground. This is achieved by using pallets or racks to elevate the billets, allowing for proper air circulation. By doing so, the chances of condensation and subsequent rusting are greatly reduced. Regular inspection and maintenance are also vital in preventing rusting. Any signs of corrosion or damage to the protective coating should be promptly addressed to ensure the integrity of the steel billets. By implementing these storage practices, steel billets can be effectively safeguarded against rusting, ensuring their quality and usability for extended periods of time.

- Q: What are the applications of steel billets in the automotive industry?

- The automotive industry relies heavily on steel billets as a crucial component, serving various roles. Engine parts, such as crankshafts, connecting rods, and camshafts, are produced by forging and machining these billets, which are essential for proper engine functionality. Similarly, suspension and steering components are manufactured using steel billets. Shaping them into control arms, tie rods, and steering knuckles ensures stability, control, and a smooth driving experience, thus guaranteeing safety and comfort. Moreover, transmission components benefit from steel billets. Gears, shafts, and other parts are forged and machined to facilitate the seamless transfer of power from the engine to the wheels, ultimately enhancing the vehicle's performance and efficiency. Furthermore, chassis and frame components are created using steel billets to provide the necessary stability and support for the entire vehicle. By incorporating billets, manufacturers can construct robust and long-lasting structures, including cross members, brackets, and reinforcements, that maintain the vehicle's structural integrity. To conclude, steel billets play a vital role in the automotive industry, serving multiple purposes. They are utilized in the production of engine parts, suspension and steering components, transmission parts, and chassis components, guaranteeing durability, performance, and safety in vehicles.

- Q: What are the main challenges in the quality control of steel billets?

- Several factors can affect the quality and performance of steel billets, posing significant challenges in their quality control. Here, we outline some key obstacles in this regard: 1. Chemical Composition: The accurate chemical composition of steel billets is pivotal in determining their strength, durability, and mechanical properties. However, ensuring consistent chemical composition is challenging due to variations in raw materials, melting processes, and the presence of impurities. 2. Homogeneity: It is crucial to achieve uniformity in the microstructure and composition throughout the steel billet. Inadequate mixing or non-uniform cooling can lead to inconsistencies, resulting in weak areas and uneven mechanical properties. 3. Defect Detection: Detecting and eliminating defects in steel billets is essential to prevent failures during subsequent processing and usage. Common defects include cracks, inclusions, segregation, porosity, and surface irregularities. However, accurately and promptly detecting these defects can be challenging due to their size, complexity, and location. 4. Dimensional Accuracy: Consistency in the dimensions and shape of steel billets is vital for their further processing and use in various applications. Maintaining precise dimensions requires controlling variables such as casting speed, cooling rates, and mold design. 5. Surface Quality: The condition of the surface of steel billets is critical for subsequent operations like rolling, forging, or machining. Ensuring a smooth, clean, and defect-free surface is challenging due to factors such as scale formation, oxidation, decarburization, and surface contamination during handling and storage. 6. Heat Treatment: Proper heat treatment is often necessary to achieve the desired mechanical properties in steel billets. However, controlling the heating and cooling rates, as well as the soaking times, can be challenging due to variations in equipment, temperature monitoring, and quenching techniques. 7. Traceability: Maintaining traceability and documentation throughout the production process is crucial for quality control. Tracking the origin of raw materials, process parameters, testing records, and certifications can be challenging, especially in complex supply chains. To address these challenges in the quality control of steel billets, a combination of advanced testing techniques, robust process controls, skilled personnel, and continuous improvement initiatives is necessary.

- Q: What are the different methods of steel billet casting?

- In the industry, various methods are commonly used for steel billet casting. These methods encompass continuous casting, ingot casting, and direct casting. Continuous casting stands as the most widely employed method for steel billet casting. In this process, molten steel is poured into a water-cooled mold, typically made of copper. As the steel cools and solidifies, a seamless billet is formed, which is subsequently cut into desired lengths. Continuous casting allows for high production rates and precise control over billet dimensions and quality. Ingot casting represents an alternative method for steel billet casting. It involves pouring molten steel into individual molds to create ingots. These ingots are then allowed to solidify before being reheated and hot rolled into billets. Ingot casting is often utilized for small-scale production or for specialty steel alloys that require specific compositions. Direct casting, also known as strand casting, emerges as a newer method for steel billet casting, eliminating the need for solidification and reheating processes. In this method, molten steel is directly poured into billets through a series of water-cooled copper molds. The billets are subsequently cooled and cut to the desired lengths. Direct casting offers advantages such as reduced energy consumption and improved yield by eliminating the intermediate steps of ingot casting. Ultimately, the selection of the steel billet casting method relies on factors like production volume, desired quality, and specific requirements of the steel alloy being produced. Each method possesses its own advantages and limitations, and choosing the appropriate method is vital for ensuring efficient and cost-effective steel billet production.

- Q: How are the surface defects of steel billets repaired?

- The surface defects of steel billets are repaired through a process called grinding or machining. This involves removing the defective areas by using specialized tools and techniques to smoothen out the surface and make it suitable for further processing or use in various industries.

- Q: How do steel billets contribute to the circular economy?

- There are several ways in which steel billets contribute to the circular economy. Firstly, they play a key role in the recycling process of steel. Steel is widely recycled around the world, and by using steel billets, scrap steel can be transformed into new products. This helps to reduce the demand for virgin iron ore and the energy-intensive processes involved in its extraction and production. Additionally, steel billets can be made from various sources, including industrial waste, automotive scrap, and construction waste. This allows for the repurposing of materials that would otherwise be disposed of in landfills, thereby reducing waste and conserving resources. By utilizing steel billets made from recycled materials, the industry can promote a more sustainable and environmentally friendly approach to steel production. Moreover, steel billets are highly versatile and can be applied in a wide range of situations. This versatility extends the lifespan of steel products and reduces the need for replacement. In the circular economy, the objective is to maximize resource utilization, and steel billets contribute to this by enabling the production of durable and long-lasting steel goods. Lastly, the circular economy places great importance on closing the loop and ensuring that materials are reused or recycled at the end of their life cycle. Steel billets facilitate this process as they are readily available for the production of new steel products. This not only reduces reliance on virgin materials but also minimizes the environmental impact associated with the extraction and processing of raw materials. In summary, steel billets play a crucial role in the circular economy by enabling steel recycling, repurposing waste materials, promoting durability, and closing the loop in the steel production process. Their use contributes to resource conservation, waste reduction, and the overall sustainability of the steel industry.

- Q: How are steel billets used in the production of hydraulic cylinders?

- Hydraulic cylinders rely on steel billets as a crucial raw material for their production. These billets, which are cylindrical and made of high-quality steel, serve as the starting point for the manufacturing process. To begin, the steel billets are heated in a furnace. This heating process, known as hot rolling, makes the billets more malleable and easier to work with. Once heated, the billets are then passed through a series of rollers, shaping and elongating them to the desired size and form. After the initial shaping, the billets undergo further processing through various machining operations. These operations include drilling, boring, milling, and grinding, among others. By using these machining processes, the necessary features and dimensions for hydraulic cylinders, such as piston and rod bores, mounting holes, and fluid flow ports, are created. Once the machining operations are complete, the billets are subjected to heat treatment to improve their mechanical properties. The specific heat treatment method, either quenching and tempering or annealing, depends on the hydraulic cylinder's requirements. Heat treatment enhances the steel's strength, hardness, and durability, ensuring that the hydraulic cylinder can withstand the high pressures and forces it will encounter during operation. After shaping, machining, and heat treatment, the steel billets are ready for the final assembly stage. Other components, such as pistons, rods, seals, and valves, are added to complete the hydraulic cylinder. These components are carefully integrated with the billets to ensure proper functionality and reliable performance. In conclusion, steel billets are essential for the production of hydraulic cylinders. They undergo heating, shaping, machining, heat treatment, and assembly to form the core structure of the cylinder. This guarantees that the hydraulic cylinder possesses the necessary strength, durability, and precision required for efficient operation in a variety of industrial and mobile applications.

- Q: How do steel billets contribute to the chemical industry?

- The chemical industry heavily relies on steel billets as a vital raw material for the production of various chemicals and chemical products. These solid bars or rods of steel play a critical role in the manufacturing process. To begin with, in chemical production plants, steel billets are utilized in the fabrication of reactors and vessels. These reactors are specifically designed to withstand extreme temperatures and pressure. Steel billets provide the necessary strength and durability to ensure the integrity of these applications. The chemical reactions occurring within these reactors often involve corrosive or harsh chemicals, and the use of steel billets guarantees that the equipment remains intact, preventing any potential leaks or accidents. Furthermore, steel billets are also essential in the production of catalysts, substances that facilitate chemical reactions without being consumed in the process. Many catalysts are composed of metals or metal oxides, and steel billets are commonly employed as the foundational material for their manufacturing. By providing a stable and robust foundation, steel billets contribute to the efficiency and effectiveness of these catalysts. Additionally, steel billets are employed in the construction of pipelines and storage tanks, which are crucial for the transportation and storage of chemicals. These structures must withstand high pressures and corrosive environments, making steel billets the preferred material due to their strength, durability, and resistance to chemical degradation. They ensure the secure and efficient transportation and storage of chemicals, which is of utmost importance in the chemical industry. In conclusion, steel billets are indispensable in the chemical industry due to their strength, durability, and resistance to chemical degradation. They are utilized in the construction of reactors, vessels, catalysts, pipelines, and storage tanks, all of which are vital components of chemical production and transportation. Without steel billets, the chemical industry would face significant challenges in operating efficiently and safely.

- Q: How are steel billets used in the manufacturing of power transmission towers?

- Steel billets are an integral component in the manufacturing of power transmission towers. These towers, which are used to support electrical power lines, require a strong and durable material to withstand the weight and stress of the overhead cables. Steel billets, which are essentially semi-finished steel products, serve as the raw material for the fabrication of power transmission towers. The billets are typically made of high-quality steel, which possesses excellent strength and structural properties. The manufacturing process begins with the selection and preparation of steel billets. These billets are heated to a specific temperature, known as the forging temperature, in a furnace. Once the billets reach the desired temperature, they are transferred to a rolling mill, where they are shaped and formed into the required sections for the power transmission towers. Using various rolling techniques, the heated steel billets are transformed into long, slender sections known as angles, channels, or I-beams. These sections are carefully crafted to provide the necessary structural integrity and load-bearing capacity required for power transmission towers. Once the steel sections are formed, they undergo further processes such as cutting, drilling, and welding to create the tower's components. These components include the legs, braces, cross arms, and other reinforcements that make up the tower structure. The steel billets used in the manufacturing of power transmission towers are crucial for ensuring the towers' strength, stability, and longevity. Steel's high strength-to-weight ratio makes it an ideal material for supporting the weight of the cables and withstanding external forces such as wind and ice loads. Additionally, steel's resilience and durability make it capable of withstanding harsh environmental conditions, including extreme temperatures and corrosive elements. In conclusion, steel billets are a fundamental material used in the manufacturing of power transmission towers. Through a series of heating, rolling, and fabrication processes, these billets are transformed into the various structural sections and components that make up the towers. The use of steel ensures that the power transmission towers possess the necessary strength, stability, and resilience to support the electrical power lines effectively.

Send your message to us

Steel Billet steel Billet for Sale 3SP 5SP 20MnSi for Fireplace Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords