Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk /JH

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $300-350 and Usually I will quote you CIF price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

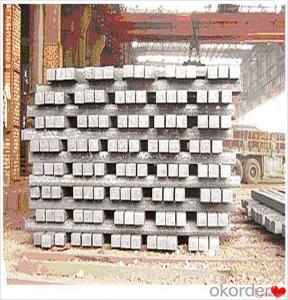

Product image:

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

- Q: What are the common types of steel products used in the pet photography and videography industry?

- The common types of steel products used in the pet photography and videography industry include tripods, light stands, backdrop stands, and camera rigging systems. These steel products provide stability, durability, and support for capturing high-quality pet photographs and videos.

- Q: How are steel forgings used in the production of mining equipment?

- Steel forgings are used in the production of mining equipment because of their superior strength and durability. They are used to create critical components such as gears, shafts, and axles, which need to withstand the harsh conditions and heavy loads encountered in mining operations. By utilizing steel forgings, mining equipment manufacturers can ensure the reliability and longevity of their products, increasing the overall efficiency and safety of mining operations.

- Q: How is steel wire used in the production of cables?

- Steel wire is commonly used in the production of cables as a strength member or reinforcement. It provides structural integrity and durability, allowing the cable to withstand tension and prevent stretching or breaking. Steel wire is typically used in power cables, suspension bridges, elevator cables, and various other applications where strength and reliability are essential.

- Q: What are the applications of steel in the petrochemical industry?

- Steel has numerous applications in the petrochemical industry due to its exceptional strength, durability, and resistance to extreme temperatures and corrosive environments. It is extensively used in the construction of storage tanks, pipelines, and equipment for the processing and transportation of petrochemicals. Additionally, steel is utilized in the fabrication of heat exchangers, reactors, and furnaces, where it plays a crucial role in maintaining operational efficiency and safety.

- Q: What are the uses of steel wire mesh?

- Steel wire mesh has a wide range of uses, including reinforcing concrete structures, providing security in fencing and gates, preventing animals from entering certain areas, filtering and sieving materials, supporting and reinforcing walls and ceilings, and creating partitions or barriers in construction and industrial applications.

- Q: How is steel used in the production of defense equipment?

- Steel is commonly used in the production of defense equipment due to its strong and durable properties. It is used to manufacture various components, such as armor plates, ballistic helmets, and weapon systems, to provide protection and withstand high-stress situations. Additionally, steel is also utilized in the construction of military vehicles, submarines, and aircraft carriers, ensuring their structural integrity and enhancing their overall strength and resilience.

- Q: What are the different types of steel roofing systems?

- There are several different types of steel roofing systems available, including standing seam, corrugated, and stone-coated steel. Each type offers its own unique benefits and aesthetic appeal.

- Q: What are the key characteristics of stainless steel?

- Some key characteristics of stainless steel include its high resistance to corrosion, its durability and strength, its low maintenance requirements, and its ability to withstand high and low temperatures. It also has a sleek and polished appearance, making it popular in various industries such as construction, automotive, and kitchenware.

- Q: What are the advantages of using steel in the construction of sports stadiums?

- There are several advantages of using steel in the construction of sports stadiums. Firstly, steel is a highly durable material, capable of withstanding heavy loads and extreme weather conditions. This ensures the long-term safety and structural integrity of the stadium. Secondly, steel offers great flexibility in design, allowing architects to create unique and innovative stadium structures. Additionally, steel is lightweight compared to other construction materials, which simplifies the construction process and reduces costs. Furthermore, steel is a sustainable and environmentally friendly choice, as it is often made from recycled materials and can be easily recycled at the end of its lifespan. Overall, these advantages make steel an ideal choice for constructing sports stadiums.

- Q: How are steel bars used in the construction of high-rise buildings?

- Steel bars are commonly used in the construction of high-rise buildings as reinforcement in concrete structures. They provide added strength and durability to the building, helping it withstand the immense loads and forces it experiences. Steel bars are typically placed within the concrete columns, beams, and slabs, forming a skeletal framework that supports the structure. This steel reinforcement helps prevent cracks, increases the building's resistance to earthquakes and other external forces, and ensures the overall structural integrity of the high-rise building.

Send your message to us

Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk /JH

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords