Continuous Casting Steel Billet 3SP 5SP 20MnSi Multifunctional

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continuous Casting Steel Billet 3SP 5SP 20MnSi Multifunctional

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

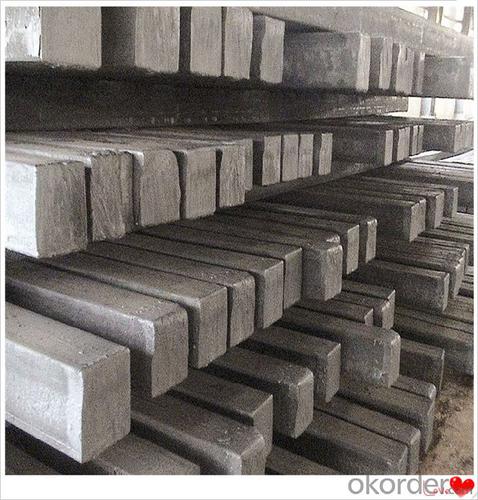

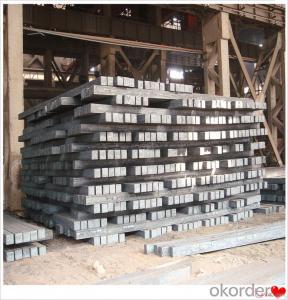

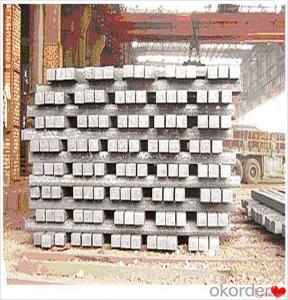

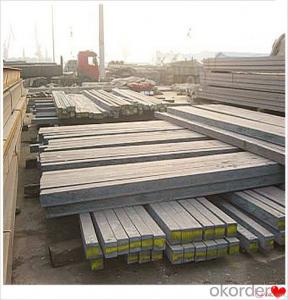

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How do steel billets contribute to the manufacturing of machinery and equipment?

- Steel billets play a crucial role in the manufacturing of machinery and equipment. These billets, which are essentially semi-finished steel products, are used as raw materials in various manufacturing processes. One of the primary ways steel billets contribute to the manufacturing of machinery and equipment is through the production of steel bars and rods. Steel billets are heated and then rolled or forged into these shapes, which are essential components in the construction of machinery and equipment. Steel bars and rods provide strength, durability, and stability to the structures of machines. Furthermore, steel billets are also used in the production of other steel components like gears, crankshafts, and axles. These components are vital for the proper functioning of machinery and equipment and require the high strength and toughness provided by steel billets. By using steel billets, manufacturers can ensure that their machinery and equipment can withstand heavy loads, vibrations, and other demanding conditions. In addition, steel billets are often used to produce steel pipes and tubes, which are widely used in various industries. These pipes and tubes are essential for the transportation of fluids, gases, and other materials within machinery and equipment. By using steel billets, manufacturers can produce pipes and tubes that are not only strong and durable but also resistant to corrosion and wear. Moreover, steel billets contribute to the manufacturing of machinery and equipment by enabling the production of precision-engineered components. These billets can be machined, drilled, and shaped to meet the specific requirements of different machinery and equipment. This flexibility allows manufacturers to create intricate and complex components that are essential for the efficient operation of machines. Overall, steel billets are an integral part of the manufacturing process for machinery and equipment. They provide the necessary strength, durability, and versatility required to produce components that can withstand the demanding conditions of industrial applications. Without steel billets, the manufacturing industry would struggle to produce machinery and equipment that are reliable, efficient, and long-lasting.

- Q: 100Q235 steel can only be rolled from billets of Q235?Or a billet can be rolled into Q195~Q215 and other models of steel?Is there a detailed classification of billets? Do you have GB?

- The same type of steel, such as low carbon steel, the grade and composition design, but also look at the performance, therefore, a steel production process due to the abnormal quality, by the high grade and low grade sentenced to drop, but sales loss.......

- Q: How are steel billets used in the production of automotive suspension components?

- Steel billets are used in the production of automotive suspension components due to their strength, durability, and malleability. Billets are essentially semi-finished steel products that are formed into specific shapes, such as bars or rods, through a process called hot rolling. In the case of automotive suspension components, steel billets are first heated to a high temperature and then passed through a series of rollers to shape them into the desired form, such as coil springs, shock absorber rods, or stabilizer bars. The hot rolling process helps to refine the grain structure of the steel, resulting in improved mechanical properties. The use of steel billets in suspension components is crucial as they provide the necessary strength and stiffness to withstand the various forces and loads encountered during vehicle operation. Suspension components, such as coil springs, are responsible for supporting the weight of the vehicle and providing a comfortable ride by absorbing impacts and vibrations. Steel billets are preferred for automotive suspension components due to their high tensile strength, which allows them to withstand heavy loads and maintain their shape over long periods. Additionally, the malleability of steel allows for easy forming and shaping into various complex geometries, ensuring a precise fit and functionality within the suspension system. Moreover, steel billets offer excellent fatigue resistance, which is crucial for suspension components as they undergo repetitive loading and unloading throughout the vehicle's lifespan. This fatigue resistance helps to prevent failure and ensures a long-lasting and reliable suspension system. Overall, the use of steel billets in the production of automotive suspension components is essential for achieving the necessary strength, durability, and performance required for safe and comfortable vehicle operation.

- Q: What are the main characteristics of high-quality steel billets?

- High-quality steel billets possess several key characteristics that differentiate them from other types of steel. Firstly, their chemical composition is of superior quality. This means that they are crafted using carefully selected raw materials, resulting in the perfect balance of elements necessary for optimal strength, durability, and resistance to corrosion. The chemical composition plays a vital role in determining the overall quality and performance of the steel billets. Secondly, high-quality steel billets display a uniform and refined microstructure. This indicates that the grains within the steel are evenly distributed and have undergone meticulous refinement during the manufacturing process. This uniform and refined microstructure significantly enhances the strength and toughness of the steel, rendering it more resistant to cracking, deformation, and other types of mechanical stress. Furthermore, high-quality steel billets boast precise dimensions. They are manufactured with stringent tolerances to ensure that they possess the accurate length, width, and thickness required. These precise dimensions are crucial as they facilitate easy and accurate machining, forging, or rolling of the billets into the desired end products. This guarantees that the final products created from these billets possess consistent and accurate dimensions. Lastly, high-quality steel billets exhibit excellent surface quality. They are devoid of any defects, such as cracks, scale, or other surface imperfections. A smooth and clean surface allows for improved heat transfer, enhanced weldability, and an overall superior appearance of the final products. It also ensures that the billets can be effortlessly inspected and processed without encountering any hindrances. Ultimately, high-quality steel billets possess superior chemical composition, uniform and refined microstructure, precise dimensions, and excellent surface quality. These characteristics are indispensable in manufacturing steel billets that adhere to the highest standards of strength, durability, and reliability, making them suitable for a wide range of industrial applications.

- Q: Can steel billets be used for making decorative items?

- Certainly, decorative items can be made using steel billets. Steel, being a versatile and sturdy material, can be molded and shaped into various forms. Skilled craftsmen can transform steel billets into stunning decorative pieces like sculptures, furniture, wall art, and other ornamental items. Moreover, steel's durability and longevity make it an excellent choice for decorative items that need to endure over time. Furthermore, steel can be finished in different ways, such as polishing, painting, or incorporating other decorative elements, which further enhance its aesthetic appeal. Therefore, steel billets present enormous potential for creating one-of-a-kind and visually captivating decorative items.

- Q: What are the different types of steel billet reheating furnaces?

- There are several different types of steel billet reheating furnaces used in the metal industry. These furnaces are designed to heat steel billets to a specific temperature before they are further processed or shaped into various end products. The main types of steel billet reheating furnaces include: 1. Pusher Type Furnace: This type of furnace uses a pusher mechanism to move the billets through the furnace. The billets are loaded onto a roller conveyor and pushed into the furnace using mechanical pusher plates. As the billets move through the furnace, they are heated by the combustion gases or electrical heating elements. 2. Walking Beam Furnace: In a walking beam furnace, the billets are placed on a series of moving beams or skids. These beams move in a continuous loop, carrying the billets through the furnace. As the billets move, they are heated by the burners or electrical heating elements located above and below the beams. 3. Rotary Hearth Furnace: This type of furnace consists of a rotating hearth on which the billets are placed. The hearth rotates, bringing the billets through different temperature zones within the furnace. The billets are heated by the burners or electrical heating elements located above the hearth. 4. Continuous Furnace: A continuous furnace is a type of furnace where the billets are continuously fed into one end and discharged from the other end. The billets move through the furnace on a conveyor belt or roller conveyor, being heated by the combustion gases or electrical heating elements as they pass through. 5. Walking Hearth Furnace: In a walking hearth furnace, the billets are placed on a hearth that moves in a reciprocating motion. The hearth moves back and forth, bringing the billets through the furnace. The billets are heated by the burners or electrical heating elements located above and below the hearth. Each type of steel billet reheating furnace has its own advantages and is suitable for specific applications. The choice of furnace depends on factors such as the required heating capacity, the size and shape of the billets, the desired temperature profile, and the energy efficiency requirements.

- Q: What is the typical yield strength of a steel billet?

- The typical yield strength of a steel billet varies depending on the specific grade and composition of the steel. However, it is generally in the range of 250 to 500 megapascals (MPa).

- Q: What are the different methods used for heating steel billets?

- There are several different methods used for heating steel billets, depending on the specific requirements and constraints of the application. Some of the common methods include: 1. Induction Heating: This method uses electromagnetic induction to heat the steel billets. An alternating current is passed through a coil, creating a magnetic field that induces electrical currents in the billet, generating heat. Induction heating provides precise and controllable heating, allowing for uniform heating throughout the billet. 2. Gas Furnaces: Gas furnaces utilize burners to generate heat, which is then transferred to the steel billets through convection. Natural gas or propane is commonly used as the fuel source. Gas furnaces offer flexibility in terms of temperature control, heating rate, and energy efficiency. 3. Electric Resistance Heating: In this method, electric current is passed through resistive elements, such as heating elements or heating pads, that are in direct contact with the steel billets. The resistance to the electric current generates heat, which is transferred to the billets. Electric resistance heating is commonly used for smaller-scale operations or applications with specific heating requirements. 4. Flame Heating: Flame heating involves the use of an open flame, typically generated by a gas burner, to heat the steel billets. The billets are heated by the radiant heat emitted from the flame. Flame heating is often used for larger billets or in applications where rapid heating is required. 5. High-Frequency Heating: High-frequency heating utilizes electromagnetic fields to heat the billets. The billets are placed inside a coil, and a high-frequency alternating current is passed through the coil, inducing electrical currents in the billets. The resistance to the electrical currents generates heat, resulting in rapid and uniform heating. 6. Laser Heating: Laser heating involves the use of high-powered lasers to heat the steel billets. The laser beam is focused on the surface of the billet, generating intense heat through the absorption of the laser energy. Laser heating offers precise and localized heating, making it suitable for specific applications or for heat treating small areas of the billets. These are just a few of the methods commonly used for heating steel billets. The choice of method depends on factors such as the required heating rate, temperature control, energy efficiency, and the specific characteristics of the billets being heated.

- Q: What is the typical elongation of a steel billet?

- The elongation of a steel billet can vary depending on factors such as the grade of steel, manufacturing process, and intended application. Typically, the elongation falls between 20% to 30%. Elongation measures a material's ability to stretch before breaking, expressed as a percentage. It is determined through a tensile test where a sample is subjected to increasing forces until it fractures. The amount of elongation is determined by comparing the sample's initial and final lengths. Steel is known for its high tensile strength and some degree of ductility. A steel billet can stretch by 20% to 30% of its original length before breaking. Different steel grades have varying elongation properties. Higher carbon steels have lower elongation values compared to low carbon or mild steels. Manufacturing processes like hot rolling or cold drawing can also affect the steel's microstructure and elongation characteristics. The required elongation for a steel billet depends on its intended application. Industries like construction or automotive may require higher elongation values to endure the stresses it will face. Other applications may prioritize tensile strength over elongation.

- Q: What is the lifespan of steel billets?

- The lifespan of steel billets can vary depending on various factors such as the quality of the steel, the conditions in which they are stored, and the specific application they are being used for. Generally, steel billets can have a relatively long lifespan if they are properly stored and maintained. In ideal conditions, steel billets can last for several years without any significant degradation. However, if the billets are exposed to harsh environmental factors such as moisture, extreme temperatures, or corrosive substances, their lifespan may be significantly reduced. It is important to handle and store steel billets carefully to minimize any potential damage and ensure their longevity.

Send your message to us

Continuous Casting Steel Billet 3SP 5SP 20MnSi Multifunctional

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords