Carbon Steel Billet 3SP 5SP 20MnSi New design Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Steel Billet 3SP 5SP 20MnSi New design Steel Billet

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

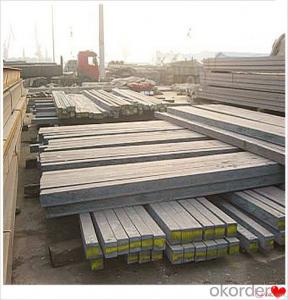

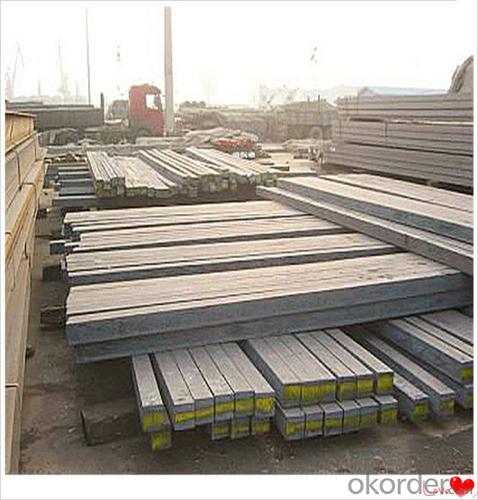

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How to purchase suitable billet heating furnace

- Billet heating furnace manufacturers are many, the procurement of cost-effective equipment is the user's best choice. Choice can not be blind, you can not just look at the price, the choice of advice you consult more manufacturers, and then use the exclusion method to determine your final goal. Online can take a look at live video, more reference.

- Q: How can steel billets be recycled or reused?

- There are several ways to recycle and reuse steel billets. A common method involves melting down the billets and using the resulting molten steel to create new products. This process, known as remelting, allows for the steel to be utilized in a variety of applications. Another option is to incorporate the steel billets into the production of other steel products. For instance, they can be utilized to produce steel rods, pipes, or beams. By integrating the billets into the manufacturing process, the steel industry can minimize waste and decrease the necessity for extracting new raw materials. Construction projects can repurpose steel billets as well. They can serve as raw material for constructing structures like bridges, buildings, or highways. By using recycled steel billets, construction projects can lessen their environmental impact and contribute to a more sustainable future. Moreover, steel billets can be transformed into smaller components through processes like rolling or forging. These components can then be employed in various industries, including automotive, machinery, and infrastructure. By reusing steel billets in this manner, we can decrease the need for producing new materials and conserve resources. In summary, recycling and reusing steel billets offer numerous advantages, including waste reduction, resource conservation, and sustainability promotion. By implementing proper recycling and reuse practices, steel billets can have a second life in various industries, thus becoming a valuable resource in the circular economy.

- Q: What are the different types of steel billet rolling processes?

- There are several different types of steel billet rolling processes that are used in the manufacturing industry. These processes include hot rolling, cold rolling, and warm rolling. Hot rolling is the most common and widely used method for producing steel billets. In this process, the steel billet is heated to a high temperature and then passed through a series of rolling mills to reduce its thickness and shape it into the desired form. The high temperature softens the steel and makes it more malleable, allowing it to be easily shaped and formed. Cold rolling, on the other hand, is a process where the steel billet is rolled at room temperature or slightly below. This process is typically used for producing steel billets with a higher level of precision and a smoother surface finish. Cold rolling also helps to improve the mechanical properties of the steel, making it stronger and more durable. Warm rolling is a combination of hot rolling and cold rolling. In this process, the steel billet is heated to a temperature that is lower than in hot rolling but higher than in cold rolling. The lower temperature helps to preserve the mechanical properties of the steel while still allowing for some shaping and forming. Each of these steel billet rolling processes has its own advantages and disadvantages. Hot rolling is the most cost-effective and efficient method, but it may result in some surface defects. Cold rolling provides a higher level of precision and surface finish, but it is more expensive and time-consuming. Warm rolling offers a balance between the two, but it may not be suitable for all applications. Overall, the choice of steel billet rolling process depends on various factors such as the desired shape and properties of the final product, the production volume, and the cost considerations.

- Q: What is the typical hardness of a steel billet?

- The typical hardness of a steel billet can vary depending on the specific grade and manufacturing process, but it generally falls within the range of 150 to 300 HB (Brinell hardness).

- Q: How do steel billets contribute to energy efficiency?

- Steel billets contribute to energy efficiency in several ways: 1. Production efficiency: Steel billets are the initial form of steel that is used in various manufacturing processes. By using steel billets as a starting material, manufacturers can achieve greater production efficiency. The uniform size and shape of billets allow for easier handling, cutting, and shaping, reducing energy consumption during the manufacturing process. 2. Resource optimization: Steel billets are typically made from recycled steel scrap. By using recycled steel as the raw material, manufacturers reduce the need for extracting and processing virgin iron ore, which is an energy-intensive process. This helps in conserving natural resources and reducing the overall energy consumption associated with steel production. 3. Heat recovery: During the manufacturing of steel billets, high temperatures are required to melt and shape the steel. However, modern steel plants are equipped with advanced technologies that allow for efficient heat recovery. The excess heat generated during the process can be captured and utilized for various purposes, such as generating steam or heating other areas of the plant. This heat recovery system helps to reduce energy wastage and increase overall energy efficiency. 4. Energy-efficient equipment: Steel billet production often involves the use of heavy machinery and equipment. Manufacturers are increasingly investing in energy-efficient technologies and equipment to reduce energy consumption. For example, using more efficient electric arc furnaces or induction heating systems can significantly reduce energy requirements compared to traditional methods. These advancements in technology contribute to the overall energy efficiency of steel billet production. Overall, steel billets play a crucial role in energy efficiency within the steel industry. From production efficiency to resource optimization and heat recovery, the use of steel billets helps in minimizing energy consumption and promoting a more sustainable steel manufacturing process.

- Q: What are the main factors that determine the sustainability of steel billets production?

- Several key factors determine the sustainability of steel billets production. Firstly, the choice of raw material source plays a crucial role. Utilizing recycled scrap metal as the primary raw material reduces the need for new mining and extraction of iron ore, thus minimizing the environmental impact associated with resource extraction. Secondly, sustainability is influenced by energy consumption during the production process. Given that steel production is energy-intensive, the type of energy sources utilized greatly impacts sustainability. The adoption of renewable energy, such as solar or wind power, can significantly reduce the carbon footprint of steel billets production. Thirdly, the efficiency of production processes and technologies employed is vital for sustainability. Modern technologies, like electric arc furnaces, offer higher energy efficiency and emit fewer greenhouse gases compared to traditional blast furnaces. Additionally, implementing waste heat recovery systems and optimizing material usage further enhances the sustainability of steel billets production. Proper management of by-products and waste generated during production is another crucial factor. Ensuring appropriate handling, treatment, and disposal of by-products and waste materials, such as slag and dust, is essential to minimize environmental pollution and ensure sustainability. Furthermore, the overall sustainability of steel billets production is influenced by the adoption of responsible and ethical practices throughout the supply chain. This includes upholding labor rights, maintaining health and safety standards, and engaging with the community. Lastly, regulatory frameworks and government policies have a significant impact on sustainability. Stringent environmental regulations, support for clean technologies, and incentives for sustainable practices can encourage the industry to adopt more environmentally friendly production methods. In conclusion, the sustainability of steel billets production is determined by factors such as the raw material source, energy consumption, production processes, waste management, ethical practices, and regulatory frameworks. By addressing these factors, the steel industry can strive towards more sustainable and environmentally friendly production practices.

- Q: What are the different surface treatments applied to alloy steel billets?

- Enhancing the properties and performance of alloy steel billets can be achieved through various surface treatments. One commonly used treatment involves bombarding the billet surface with small metal or ceramic particles at high velocity, a process known as shot blasting. This effectively eliminates impurities and contaminants, resulting in a clean and uniform surface finish. Additionally, shot blasting promotes the adhesion of subsequent coatings or treatments. Another method, known as pickling, entails immersing the billets in an acid solution to remove oxides and scale from the surface. This not only improves the surface quality but also eliminates any defects, preparing the billets for further processing or treatments. Heat treatment is a popular surface treatment for alloy steel billets. By subjecting the billets to controlled heating and cooling processes, their microstructure can be altered, leading to improved mechanical properties. This treatment can enhance the hardness, strength, and toughness of the billets, rendering them more suitable for specific applications. Furthermore, alloy steel billets can be coated with protective coatings to enhance corrosion resistance and durability. Common techniques include hot-dip galvanizing, electroplating, and painting. These coatings serve as a barrier between the alloy steel surface and the environment, effectively preventing corrosion and extending the lifespan of the billets. To summarize, shot blasting, pickling, heat treatment, and protective coatings are among the various surface treatments applied to alloy steel billets. These treatments enhance surface quality, improve mechanical properties, and protect against corrosion, ensuring optimal performance in diverse applications.

- Q: How are steel billets used in the manufacturing of industrial compressors?

- Industrial compressors require steel billets as a crucial part of their manufacturing process. These billets, essentially semi-finished steel products in the shape of a rectangular solid, are the starting material for making different compressor components. To begin with, steel billets are heated to high temperatures and then passed through rolling mills to shape them into specific forms like bars, rods, or sheets. These processed steel billets are then used to fabricate important compressor components such as the crankshaft, connecting rods, cylinder blocks, and piston rings. The crankshaft, which converts the piston's reciprocating motion into rotational motion, is typically forged from a steel billet. The billet undergoes controlled heating, shaping, and machining processes to achieve the desired shape and strength necessary to withstand the high pressures and forces within the compressor. Likewise, connecting rods, responsible for connecting the piston to the crankshaft, are also made from steel billets. These billets are machined precisely and undergo various heat treatment processes to ensure optimal strength and durability. Cylinder blocks, the primary structural frame of the compressor, are often casted from steel billets. The billets are melted and poured into molds to achieve the desired shape. Once solidified, further machining is performed on the cylinder block to create the cylinder bores, mounting surfaces, and other necessary features. Moreover, steel billets are utilized for producing piston rings, which play a crucial role in maintaining proper compression and preventing leakage. The billets are machined and then subjected to heat treatment processes to enhance wear resistance and ensure a precise fit within the cylinder. In summary, steel billets are indispensable in the manufacturing of industrial compressors as they provide the raw material for creating vital components. The ability to shape and process steel billets enables the production of robust, durable, and high-performance compressors capable of meeting the demanding requirements of various industries.

- Q: What are the different surface finishes available for steel billets?

- There are several surface finishes available for steel billets, including mill finish, hot rolled pickled and oiled (HRPO), cold rolled, galvanized, and coated finishes. These finishes enhance the appearance, protect against corrosion, improve surface smoothness, and provide specific properties required for different applications.

- Q: What is the role of steel billets in the production of valves and fittings?

- Valves and fittings, which are crucial in industries like oil and gas, petrochemical, and water treatment, rely heavily on steel billets. These billets, derived from molten steel, serve as the starting point for producing these components. To meet specific requirements, the billets are cast into shapes like round, square, or rectangular. The usage of steel billets enables manufacturers to maintain consistent quality and performance in valves and fittings. The selection process involves considering factors such as chemical composition, mechanical properties, and microstructure to guarantee the desired characteristics in the end product. After obtaining the steel billets, they undergo various manufacturing processes like forging, machining, and heat treatment. These processes further enhance the strength, integrity, and functionality of the final valve and fitting components. One of the advantages of steel billets is their versatility in customization. They can be easily cut, shaped, and formed to create valves and fittings with different sizes, configurations, and designs. This flexibility allows them to meet the specific requirements of different applications and industries. In summary, steel billets serve as the raw material for valves and fittings, playing a vital role in their production. Their strength, durability, and customization capabilities ensure the reliability and performance of these components in various industrial settings.

Send your message to us

Carbon Steel Billet 3SP 5SP 20MnSi New design Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords