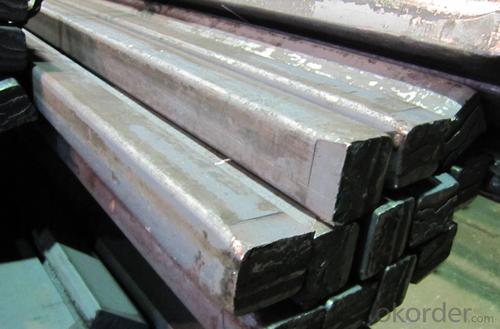

Q235/3SP 130MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 130MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 130MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 130MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 130MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 130MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the specifications for alloy steel billets used in the aerospace industry?

- The specifications for alloy steel billets used in the aerospace industry typically include specific chemical composition requirements, such as precise percentages of various alloying elements, to ensure desired mechanical properties and performance. These billets often need to meet stringent standards for strength, durability, and resistance to fatigue and corrosion. Additionally, they may need to adhere to specific dimensional tolerances, surface finish requirements, and undergo various testing and inspection procedures to ensure their suitability for aerospace applications.

- Q: What are the main factors affecting the corrosion resistance of stainless steel billets?

- The main factors affecting the corrosion resistance of stainless steel billets include the composition of the stainless steel alloy, specifically the percentage of chromium present, as well as the presence of other alloying elements such as nickel and molybdenum. The microstructure of the stainless steel, including the presence of ferrite and austenite phases, also plays a role in corrosion resistance. Additionally, factors such as the pH and temperature of the environment, the presence of corrosive substances, and the surface finish of the billets can affect their corrosion resistance.

- Q: How often is it? What is the range of temperature in the process of rolling? What is the temperature of the final rolling?

- The final rolling temperature is the rolling temperature of the last pass, and also the rolling temperature of the rolling pass at the last effective (very small level pass, not an effective rolling pass)

- Q: How are steel billets recycled?

- Steel billets are recycled through a process known as steel billet recycling. This process involves the collection of steel billets from various sources such as manufacturing plants, construction sites, and scrap yards. The collected steel billets are then transported to a recycling facility where they undergo a series of steps to be transformed into new steel products. The first step in steel billet recycling is sorting and cleaning. The collected billets are sorted based on their size, shape, and quality. Any impurities or foreign materials are removed during this stage. Once the billets are sorted and cleaned, they are ready for the next step in the recycling process. The second step is melting. The cleaned steel billets are then melted down in a furnace at extremely high temperatures. This melting process helps to separate any remaining impurities and allows the steel to be shaped into new forms. The molten steel is then poured into molds or cast into different shapes depending on the desired end product. After the steel has cooled and solidified, it undergoes further processing to achieve the desired specifications. This may involve rolling, forging, or extruding the steel billets to create various steel products such as bars, rods, or sheets. These newly formed steel products are then inspected for quality and undergo rigorous testing to ensure they meet industry standards. The final step in steel billet recycling is distribution and usage. The recycled steel products are transported to various industries such as construction, automotive, or manufacturing, where they are used to create a wide range of products. By recycling steel billets, we can reduce the demand for raw materials, conserve energy, and minimize environmental impact. In conclusion, steel billets are recycled through a process that involves sorting, cleaning, melting, shaping, and distributing. This recycling process allows us to reuse steel billets and transform them into new steel products, contributing to a more sustainable and environmentally friendly approach to steel production.

- Q: What is the process of heat treatment for steel billets?

- To alter the mechanical properties of steel billets, they undergo a process called heat treatment. This process is essential for increasing the steel's hardness, strength, and toughness, making it suitable for various industrial applications. The heat treatment process begins by subjecting the steel billets to controlled heating and cooling cycles. The heating stage involves raising the billets' temperature to a specific range, typically above the steel's critical point. This allows for the transformation of the steel's microstructure. Various methods, such as electric furnaces, gas furnaces, or induction heating, can be used for heating. Once the desired temperature is reached, the billets are held at that temperature for a specified period. This stage, known as soaking or holding, ensures that the heat distribution is uniform throughout the billet and allows for the homogenization of the microstructure. After the soaking stage, the billets undergo controlled cooling, which is equally important as the heating stage. The cooling rate is carefully controlled to achieve the desired properties. Cooling methods such as air cooling, oil quenching, or water quenching can be used. Each method provides different cooling rates and results in different material properties. During the cooling stage, the steel undergoes a phase transformation, resulting in the formation of different microstructures. For instance, rapid cooling through water quenching leads to the formation of martensite, a hard and brittle microstructure, while slower cooling can produce pearlite, a softer and ductile microstructure. After cooling, additional processes such as tempering or annealing may be applied to the steel billets. Tempering involves reheating the steel to a specific temperature and holding it there for a certain period, followed by controlled cooling. This process reduces brittleness and improves toughness and ductility. Annealing is another heat treatment process that involves heating the steel to a specific temperature and slowly cooling it. This process relieves internal stresses, refines the grain structure, and enhances the machinability of the steel. Overall, the heat treatment process for steel billets involves carefully controlled heating, soaking, cooling, and sometimes additional processes to achieve the desired mechanical properties. This process is crucial for enhancing the performance and durability of steel billets, making them suitable for various industrial applications such as construction, automotive, and machinery.

- Q: What are the different surface treatments for corrosion resistance in steel billets?

- There are several surface treatments available for corrosion resistance in steel billets, including hot-dip galvanizing, electroplating, and mechanical plating. Hot-dip galvanizing involves immersing the steel billets in molten zinc, creating a protective layer that prevents corrosion. Electroplating uses an electric current to deposit a layer of metal, such as zinc or chromium, onto the surface of the billets. Mechanical plating involves tumbling the billets with metal powder, typically zinc, in a rotating drum to create a protective coating. Each of these treatments provides varying degrees of corrosion resistance and can be chosen based on specific requirements and budget constraints.

- Q: How are steel billets used in the manufacturing of hydraulic equipment?

- Steel billets are commonly used in the manufacturing of hydraulic equipment as they serve as the raw material for creating various components, such as cylinders, valves, and pistons. These billets are heated and then shaped through forging or extrusion processes to form the desired hydraulic equipment parts. The strength, durability, and versatility of steel make it a preferred material choice for hydraulic equipment, enabling it to withstand the high pressures and demanding working conditions in this industry.

- Q: How are steel billets used in the production of agricultural implements?

- Steel billets are used in the production of agricultural implements by being further processed and shaped into various components such as plowshares, tillage tools, and blades. These billets serve as the raw material from which these implements are manufactured, providing the necessary strength, durability, and resistance to withstand the demanding conditions of agricultural operations.

- Q: Can steel billets be used in the production of mining equipment?

- Yes, steel billets can be used in the production of mining equipment. Steel billets are semi-finished products that are commonly used in the manufacturing industry to produce various types of steel products, including mining equipment. The high strength and durability of steel make it an ideal material for mining equipment, which often operates in harsh and demanding environments. Steel billets can be processed and shaped into different components such as gears, shafts, frames, and buckets, which are essential parts of mining equipment. Additionally, steel billets can be easily welded, machined, and heat-treated to meet the specific requirements and standards of mining equipment. Therefore, steel billets play a crucial role in the production of mining equipment by providing the necessary strength and reliability needed for safe and efficient mining operations.

- Q: How are steel billets used in the production of wire rods and bars?

- Steel billets are an essential component in the production of wire rods and bars. These billets, which are semi-finished metal products, serve as the raw material for manufacturing various types of steel products. To begin the production process, steel billets are heated to a high temperature in a furnace, known as a reheat furnace, until they reach the desired temperature for rolling. Once heated, the billets are then passed through a series of rolling mills, where they undergo hot rolling. During the hot rolling process, the steel billets are gradually shaped into wire rods or bars by repeatedly passing them through a set of rollers. This process helps to reduce the billet's cross-sectional area and increase its length, resulting in the desired shape and dimensions of the wire rods or bars. After the initial rolling, the wire rods or bars may undergo additional processes, such as cooling, surface treatment, and further shaping or cutting, depending on the specific requirements of the end product. These additional steps help to improve the mechanical properties and surface finish of the wire rods or bars. Once the wire rods or bars have been processed, they can be used in a wide range of applications. Wire rods, for example, are commonly used in the production of wires, nails, fencing, and various types of reinforcement materials. Bars, on the other hand, are often utilized in construction, manufacturing machinery, automotive parts, and other structural applications. In summary, steel billets play a crucial role in the production of wire rods and bars. They are heated and then shaped through the hot rolling process, resulting in the desired dimensions and properties of the end product. These wire rods and bars are then used in various industries for different applications, contributing to the overall development and functionality of numerous products and structures.

Send your message to us

Q235/3SP 130MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords