Carbon Steel Billets 3SP 5SP 20MnSi for Construction Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

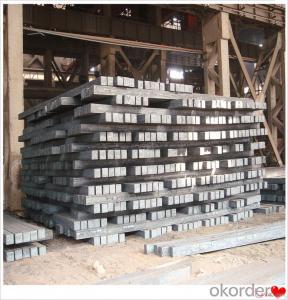

Carbon Steel Billets 3SP 5SP 20MnSi for Construction Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

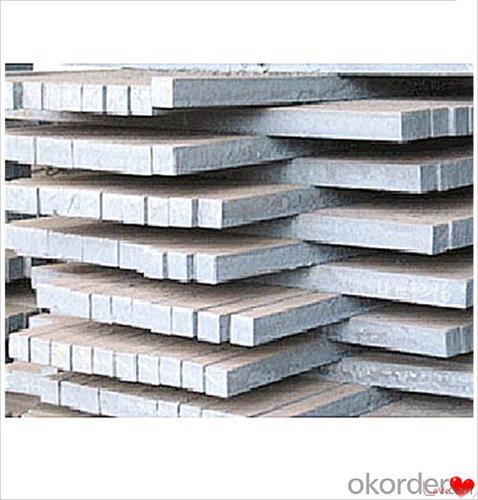

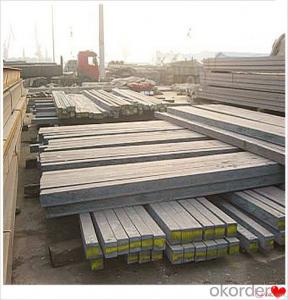

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

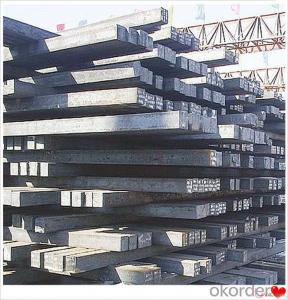

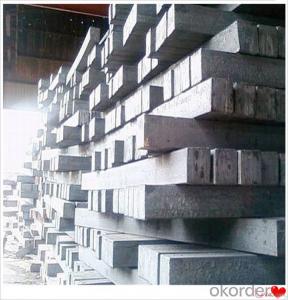

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different types of steel billet handling equipment?

- There are several different types of steel billet handling equipment used in various stages of the steel production process. These equipment are designed to efficiently move and transport steel billets, which are semi-finished metal products used for further processing. 1. Overhead Cranes: Overhead cranes are commonly used in steel mills and foundries for the handling and transportation of steel billets. These cranes have a high lifting capacity and can move billets from one location to another within the facility. 2. Mobile Cranes: Mobile cranes are versatile and can be used for handling steel billets in both indoor and outdoor environments. They are equipped with hydraulic systems for lifting and maneuvering heavy loads. 3. Forklifts: Forklifts are commonly used in warehouses and storage facilities to handle steel billets. They have forks at the front that can be raised and lowered to lift and move the billets. 4. Grab Buckets: Grab buckets are used for handling bulk materials, including steel billets. They have a bucket-like structure that can be opened and closed to grab and release the billets. These are often used in ports and shipping yards for loading and unloading billets from ships. 5. Conveyor Systems: Conveyor systems are used for continuous movement of steel billets along a predefined path. They can be used to transport billets between different stages of the production process or to load and unload them from trucks or trains. 6. Roller Tables: Roller tables are used for transferring steel billets from one conveyor or machine to another. They typically consist of a series of rollers that allow for smooth and controlled movement of the billets. 7. Magnetic Lifters: Magnetic lifters use an electromagnetic field to lift and transport steel billets. They are particularly useful when handling ferrous materials, as the magnetic force allows for secure gripping and easy movement. 8. Palletizers: Palletizers are used to stack and organize steel billets on pallets. They can automatically arrange the billets in a specific pattern, making them suitable for storage or transportation. Each type of equipment has its own advantages and is used in specific applications based on the requirements of the steel production process. The selection of the appropriate handling equipment depends on factors such as the size and weight of the billets, the distance they need to be transported, and the specific needs of the facility.

- Q: Can steel billets be coated for improved aesthetic appearance?

- Yes, steel billets can be coated with various materials such as paints, lacquers, or powder coatings to enhance their aesthetic appearance.

- Q: What are the main factors affecting the heat resistance of steel billets?

- There are several main factors that can affect the heat resistance of steel billets. Firstly, the chemical composition of the steel plays a crucial role. Elements such as carbon, chromium, and nickel can enhance the heat resistance of steel by forming stable oxide layers on the surface that act as a protective barrier against high temperatures. Additionally, the presence of alloying elements like molybdenum and vanadium can also improve the heat resistance of steel by increasing its hardenability and reducing grain growth during heat treatment. Another important factor is the microstructure of the steel. Fine-grained structures tend to have higher heat resistance due to their increased strength and reduced susceptibility to thermal fatigue. Heat treatment processes like quenching and tempering can also alter the microstructure and improve the heat resistance of steel billets. The rate of heating and cooling also affects the heat resistance of steel. Rapid heating or cooling can lead to thermal shock and result in the formation of cracks or distortion in the billets. It is essential to control the heating and cooling rates to minimize these detrimental effects and maintain the desired heat resistance. Furthermore, the presence of impurities or defects within the steel can significantly impact its heat resistance. Inclusions, such as sulfur, phosphorus, and non-metallic oxides, can act as stress concentrators and reduce the heat resistance of steel. Similarly, internal defects like voids, cracks, or segregation regions can promote crack initiation and propagation during thermal cycles, thereby reducing the overall heat resistance of the steel billets. Lastly, the mechanical properties of the steel, such as its tensile strength, hardness, and ductility, can influence its heat resistance. Higher strength and hardness can generally enhance the heat resistance, while excessive ductility may lead to deformation or failure under high-temperature conditions. In summary, the main factors affecting the heat resistance of steel billets include the chemical composition, microstructure, rate of heating and cooling, presence of impurities or defects, and the mechanical properties of the steel. Understanding and optimizing these factors can help in producing steel billets with improved heat resistance for various applications.

- Q: How do steel billets contribute to the manufacturing of construction equipment?

- Steel billets play a crucial role in the manufacturing of construction equipment. These billets are essentially semi-finished steel products that have been cast into a specific shape and size. They are typically rectangular or square in shape and serve as the starting point for further processing. One of the main ways in which steel billets contribute to the manufacturing of construction equipment is by providing a high-quality raw material. Steel is known for its exceptional strength, durability, and resistance to various environmental factors. By using steel billets, manufacturers can ensure that the construction equipment they produce will be able to withstand the harsh conditions and heavy loads that are often encountered in the construction industry. Steel billets are also used to produce various components of construction equipment. These components can include frames, beams, brackets, and other structural elements. By using steel billets, manufacturers can easily shape and form these components to meet the specific design requirements of the equipment. This flexibility allows for the creation of equipment that is not only strong and durable but also lightweight and efficient. Furthermore, steel billets are often used in the manufacturing of construction equipment due to their cost-effectiveness. Steel is a highly recyclable material, which means that it can be reused and repurposed multiple times without losing its properties. This makes steel billets a sustainable and environmentally friendly choice for manufacturers. In summary, steel billets are an essential component in the manufacturing of construction equipment. They provide a high-quality raw material that is strong, durable, and resistant to various environmental factors. Steel billets also allow for the production of customized components that meet specific design requirements. Additionally, their cost-effectiveness and recyclability make them a sustainable choice for manufacturers. Overall, steel billets contribute significantly to the production of construction equipment, ensuring that it meets the highest standards of quality and performance.

- Q: How are steel billets used in the manufacturing of railway tracks?

- Steel billets are an essential component in the manufacturing of railway tracks. These billets serve as the raw material from which the tracks are formed. The process begins with the steel billets being heated to a high temperature, typically around 1200 degrees Celsius, in a furnace. This heating process helps to soften the steel and make it more malleable. Once the billets are heated, they are passed through a series of rollers in a process known as hot rolling. This process involves the billets being continually passed through the rollers to gradually reduce their thickness and shape them into long, slender strips. This hot rolling process also helps to refine the internal structure of the steel, improving its strength and durability. After the hot rolling process, the steel strips are then cut into smaller sections, known as rails. These rails are carefully inspected for any defects or imperfections before they are further processed. They undergo a process called finishing, where any surface irregularities or imperfections are removed through grinding or polishing. The finished rails are then treated with various techniques to enhance their strength and resistance to wear and tear. This may include heat treatment processes such as quenching and tempering, which further improve the rails' hardness and toughness. Additionally, the rails may be coated with protective layers to prevent corrosion and extend their lifespan. Finally, the rails are transported to the construction site where they are laid and fastened to the sleepers or ties to form the railway track. The steel rails provide a sturdy and reliable foundation for trains to travel on, with their strength and durability enabling them to withstand heavy loads and constant use. In conclusion, steel billets play a crucial role in the manufacturing of railway tracks. They are transformed through various processes into rails that provide a solid foundation for trains to run on. The use of steel billets ensures that the railway tracks are strong, durable, and capable of withstanding the demands of heavy train traffic.

- Q: What are the different types of steel billet shearing techniques?

- There are several different types of steel billet shearing techniques used in the industry. These techniques vary based on the specific requirements of the cutting process and the desired end product. Some of the commonly used steel billet shearing techniques include: 1. Guillotine Shearing: This technique involves using a guillotine-style shear blade to cut through the steel billet. The blade is lowered onto the billet, applying a shearing force that slices through the material. 2. Circular Shearing: In this technique, a circular shear blade is used to cut through the billet. The blade rotates at a high speed, applying a cutting force as it comes into contact with the billet. 3. Band Saw Shearing: A band saw is used to cut through the steel billet in this technique. The saw blade, made of a continuous band of teeth, moves in a continuous loop, slicing through the billet as it passes through. 4. Rotary Shearing: This technique involves using a rotary shear to cut through the billet. The shear consists of a set of rotating blades that grip the billet and cut through it as it moves through the machine. 5. Flame Cutting: Also known as oxyfuel cutting, this technique uses a high-temperature flame to melt and cut through the steel billet. A stream of oxygen is directed onto the billet, creating a chemical reaction that allows for the cutting process. 6. Plasma Cutting: Plasma cutting uses a high-velocity jet of ionized gas to melt and cut through the steel billet. The gas is heated to an extremely high temperature and directed onto the billet, resulting in a clean and precise cut. Each of these steel billet shearing techniques has its own advantages and limitations, depending on factors such as the size and thickness of the billet, the required accuracy of the cut, and the desired speed of the cutting process.

- Q: What are the physical properties of steel billets?

- Steel billets possess various physical properties that render them highly suitable for a multitude of industrial applications. Primarily, they exhibit a remarkable strength-to-weight ratio, ensuring impeccable structural integrity and the ability to endure heavy loads without deformation or breakage. Another significant physical attribute of steel billets lies in their hardness. Steel is renowned for its hardness, which grants it resistance against wear and tear. Consequently, steel billets prove to be ideal for sectors where durability and long-term performance are of utmost importance, such as construction, automotive, and machinery industries. Furthermore, steel billets boast a lofty melting point, enabling them to withstand extreme heat without deformation or liquefaction. This trait proves indispensable in applications involving high temperatures, such as the manufacturing of tools, machinery, and equipment within the aerospace and energy sectors. Additionally, steel billets exhibit exceptional ductility and malleability, facilitating their effortless manipulation into diverse structures and products. This adaptability makes steel billets highly versatile and amenable to various manufacturing processes, including rolling, forging, and extrusion. Moreover, steel billets demonstrate commendable electrical and thermal conductivity, rendering them suitable for applications that necessitate efficient heat transfer and electrical conduction. These properties hold particular value in the production of electrical wiring, power transmission lines, and heat transfer equipment. In conclusion, steel billets possess key physical properties encompassing high strength, hardness, melting point, ductility, malleability, and conductivity. These attributes enable their utilization across a wide range of industries and applications, where their exceptional performance and reliability are indispensable.

- Q: What are the main challenges in manufacturing steel billets?

- There are several main challenges in manufacturing steel billets. One of the primary challenges is the need for high-quality raw materials. Steel billets are typically produced from scrap metal or iron ore, and ensuring that the raw materials meet the required specifications is crucial for producing high-quality billets. Contaminants in the raw materials can lead to defects in the final product, affecting its strength and performance. Another challenge is maintaining consistent and precise control over the manufacturing process. Steel billets need to be heated to a specific temperature and then cooled rapidly to achieve the desired metallurgical properties. This requires precise control of the heating and cooling rates, as well as the overall process parameters, such as time and pressure. Any deviations in these parameters can result in inconsistencies in the billets' properties, affecting their quality and suitability for various applications. Energy consumption is also a significant challenge in steel billet manufacturing. The process of heating and cooling the billets requires a significant amount of energy, contributing to high production costs and environmental impact. Finding ways to optimize energy usage and improve energy efficiency is a constant challenge for steel manufacturers. Furthermore, maintaining the equipment and machinery used in the production process is crucial. The high temperatures and harsh conditions in steel manufacturing can lead to wear and tear on the equipment, resulting in potential breakdowns and production delays. Regular maintenance and timely repairs are necessary to ensure smooth operations and minimize downtime. Safety is another vital challenge in steel billet manufacturing. The process involves handling heavy materials, high temperatures, and potentially hazardous chemicals. Implementing robust safety protocols, providing proper training to workers, and ensuring compliance with safety regulations are essential to create a safe working environment and prevent accidents or injuries. Lastly, market demand and competition pose challenges for steel billet manufacturers. The industry is highly competitive, and staying ahead requires continuous innovation, cost optimization, and the ability to adapt to changing market trends and demands. Meeting customer expectations, delivering on time, and maintaining high-quality standards are critical factors for success in the steel billet manufacturing industry.

- Q: What are the safety precautions when handling steel billets?

- When handling steel billets, some important safety precautions to follow include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. It is also crucial to ensure proper lifting techniques, using machinery or equipment designed for the task, to prevent strains or injuries. Additionally, maintaining a clean and organized work area, free from clutter and obstacles, can help minimize accidents and tripping hazards. Regular inspections of equipment, such as cranes or lifting devices, should be carried out to identify any potential malfunctions or defects that could compromise safety. Lastly, proper communication and training among workers is essential to ensure everyone understands and follows safety protocols when handling steel billets.

- Q: What are the potential applications of steel billets in the telecommunications industry?

- The telecommunications industry benefits greatly from the wide range of potential applications offered by steel billets. A key application lies in the construction of telecommunication towers, where steel billets serve as the foundation for manufacturing the structural components. These components provide the necessary strength and durability to support the weight of antennas and other equipment. Moreover, steel billets play a vital role in the production of transmission line hardware, including pole line fittings, brackets, and clamps. These components are crucial for ensuring the stability and reliability of telecommunication lines during installation and maintenance. Furthermore, steel billets are essential in the manufacturing of enclosures, both underground and overhead, that protect telecommunication cables from external factors such as moisture, heat, and physical damage. This protection guarantees uninterrupted communication. In addition, steel billets are utilized in the production of telecommunication equipment cabinets and racks, which provide a secure and organized space for housing network equipment, such as servers, switches, and routers. The strength and rigidity of steel billets make them ideal for supporting heavy equipment and protecting against environmental hazards. Lastly, steel billets find application in the construction of telecommunication infrastructure, including base stations and equipment shelters. These structures require robust materials to withstand harsh weather conditions and provide a stable foundation for the installation of telecommunications equipment. In conclusion, the versatility and durability of steel billets make them ideal for various aspects of the telecommunications industry, from tower construction to cable enclosures and equipment cabinets. Steel billets provide the necessary support and protection for telecommunication infrastructure and equipment.

Send your message to us

Carbon Steel Billets 3SP 5SP 20MnSi for Construction Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords