Column Steel Billet 3SP 5SP 20MnSi for Stoves Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Column Steel Billet 3SP 5SP 20MnSi for Stoves Steel Billet

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

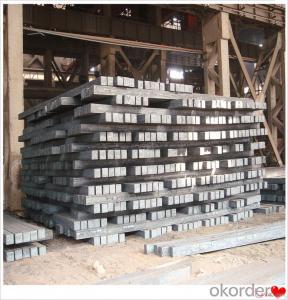

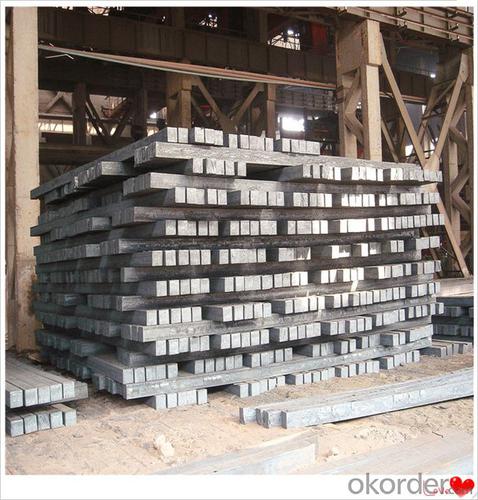

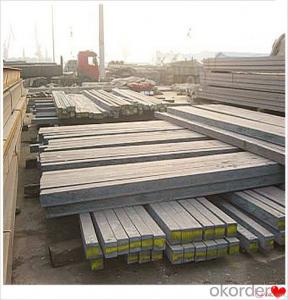

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different quality standards for steel billets?

- There are several quality standards for steel billets, including ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and EN (European Norm) standards. These standards define various parameters such as chemical composition, mechanical properties, and dimensional tolerances that steel billets must meet in order to ensure their quality and suitability for different applications.

- Q: Can steel billets be used in the automotive industry?

- Yes, steel billets can be used in the automotive industry. Steel billets are semi-finished steel products that are typically used for further processing into different shapes and forms. In the automotive industry, steel billets are commonly used for the production of various automotive components such as engine parts, transmission parts, chassis components, and suspension systems. The use of steel billets in the automotive industry offers several advantages including high strength, durability, and cost-effectiveness. Additionally, steel billets can be easily formed, machined, and welded to meet specific design requirements and performance standards in the automotive sector. Therefore, steel billets play a crucial role in the manufacturing of automobiles and contribute to the overall performance, safety, and reliability of vehicles.

- Q: What are the different surface treatments for improved surface roughness in steel billets?

- There are several surface treatments that can be used to improve surface roughness in steel billets. Some common methods include shot blasting, pickling, and mechanical polishing. Shot blasting involves propelling abrasive particles at high speeds onto the steel surface to remove any impurities and create a smoother finish. Pickling involves immersing the steel billets in an acid solution to remove oxides and scale, resulting in a cleaner and smoother surface. Mechanical polishing uses abrasive materials and tools to physically remove any imperfections and create a smoother surface. These treatments can significantly enhance the surface quality of steel billets, making them suitable for various applications.

- Q: How do steel billets compare to other forms of raw steel material?

- Steel billets are a preferred form of raw steel material due to their consistent shape and size, making them easier to handle and process. Compared to other forms like ingots or slabs, billets offer higher purity, improved mechanical properties, and better surface quality, making them ideal for various industrial applications.

- Q: What are the common shapes of steel billets?

- Depending on their intended use and manufacturing process, steel billets can be found in a range of shapes. Square, rectangular, round, and hexagonal are among the most common shapes. Square billets are typically utilized in applications that require stability and strength, such as construction materials and machinery parts. For structural components in construction and engineering projects, rectangular billets, with their elongated shape, are commonly employed. Round billets are often chosen for the production of pipes, tubes, and other cylindrical objects. As for hexagonal billets, their six-sided shape is frequently used in the manufacturing of hex nuts, bolts, and other fasteners. These various shapes offer versatility in order to meet the diverse requirements and applications of different industries.

- Q: Can steel billets be used in high-temperature applications?

- Steel billets can indeed be utilized in applications that involve high temperatures. Generally, these billets are crafted from carbon steel, which possesses commendable heat resistance characteristics. Carbon steel is capable of enduring escalated temperatures without experiencing substantial deformation or strength reduction. Nonetheless, it is crucial to contemplate the particular grade and composition of the steel billets, as dissimilar alloys might have diverse temperature thresholds. Moreover, factors such as the duration of exposure to elevated temperatures, the existence of corrosive surroundings, and the mechanical loading conditions must be considered in order to ascertain the appropriateness of steel billets for high-temperature applications.

- Q: What are the different types of defects in steel billets?

- Steel billets, which are semi-finished steel products used in various manufacturing processes, can experience different types of defects. These defects can arise during production or handling and can impact the overall quality, mechanical properties, and structural integrity of the billets. Some common defect types found in steel billets include: 1. Surface defects: These defects are visible on the outer surface of the billet and can include scratches, cracks, pits, or scale. Improper handling, storage, transportation, or manufacturing processes can cause surface defects. 2. Internal defects: These defects occur within the cross-section of the billet and are not visible to the naked eye. They can include blowholes, inclusions, segregations, or voids. Impurities in raw materials, inadequate casting or solidification processes, or insufficient quality control measures can lead to internal defects. 3. Dimensional defects: These defects refer to variations in the billet's dimensions compared to specified requirements. They can involve deviations in length, width, or thickness beyond acceptable tolerances. Improper cutting, rolling, or cooling processes during billet production can cause dimensional defects. 4. Chemical composition defects: These defects occur when the steel billet does not meet the required chemical composition specifications. Impurities in raw materials, inadequate mixing or alloying processes, or insufficient quality control during production can lead to chemical composition defects. 5. Mechanical defects: These defects impact the mechanical properties of the steel billet, such as strength, toughness, or ductility. Improper heat treatment, quenching, or tempering processes, as well as inadequate quality control during manufacturing, can result in mechanical defects. Detecting and minimizing these defects is crucial as they can negatively affect the performance and reliability of the final steel products made from the billets. Implementing quality control measures, including regular inspection and testing, can help identify and rectify any defects in steel billets, ensuring the production of high-quality finished products.

- Q: How do steel billets come out?

- Three, steel rolling:Rolling steel or continuous casting billet into various steels by rolling mill

- Q: How do steel billets contribute to the overall weight reduction of a product?

- Steel billets contribute to the overall weight reduction of a product through several key factors. Firstly, steel billets are formed through a process of hot rolling or continuous casting, which allows for precise control over the dimensions and shape of the final product. This enables manufacturers to produce steel billets with a high strength-to-weight ratio, meaning that they offer excellent structural integrity while being relatively lightweight. Additionally, steel billets can be further processed and shaped into various components of a product, such as sheets, plates, or bars. These components can be designed and optimized to have thinner cross-sections or hollow sections, reducing the weight without compromising the overall strength and performance of the product. This weight reduction is highly beneficial, especially in industries where lightweight materials are desirable, such as automotive, aerospace, or construction. Furthermore, steel billets can also be used in the production of advanced high-strength steels (AHSS) or ultra-high-strength steels (UHSS). These steels possess exceptional mechanical properties, including high tensile strength and improved formability, allowing manufacturers to use thinner gauges of steel without sacrificing durability. This, in turn, leads to a significant reduction in weight while maintaining the necessary structural integrity. In conclusion, steel billets contribute to the overall weight reduction of a product by providing a lightweight yet strong material for manufacturing. Their ability to be shaped into various components, combined with advancements in steel technology, allows for the production of lightweight products without compromising strength or performance.

- Q: What are the different types of steel billet casting defects?

- During the casting process of steel billets, various types of defects may occur, impacting the final product's quality and performance. These defects can range in severity and have different effects on the billets. Common defects include: 1. Insufficient feeding of liquid metal during solidification can cause shrinkage defects, resulting in voids or cavities within the billet. This weakens the billet's strength and may lead to failure under stress. 2. Porosity defects are characterized by the presence of small gas bubbles or voids within the billet. They reduce density, weaken the material, and affect mechanical properties such as tensile strength and ductility. 3. Foreign substances, such as non-metallic particles, oxides, or impurities, can become trapped within the billet, resulting in inclusion defects. These negatively impact mechanical properties like ductility and increase brittleness. 4. Surface defects, like cracks, scabs, or uneven surfaces, can occur during casting, affecting the appearance and structural integrity of the billet. 5. Uneven distribution of alloying elements within the billet leads to segregation defects. This inconsistency in composition affects mechanical properties and overall performance. 6. During solidification, thermal stresses can cause cracks known as hot tears, weakening the billet and reducing its strength under stress. 7. When the liquid metal fails to completely fill the mold cavity, misruns occur, resulting in incomplete billets. This defect leads to reduced dimensions, poor surface finish, and compromised mechanical properties. Addressing and identifying these defects is crucial to ensure the production of high-quality and reliable steel products. Techniques such as proper mold design, controlling casting parameters, and process optimization can be employed to minimize these defects and improve the overall quality of the billet.

Send your message to us

Column Steel Billet 3SP 5SP 20MnSi for Stoves Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords