Steel Square Bar Hot Rolled 5MM-28MM High Quality Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Square Bar Hot Rolled 5MM-28MM High Quality Hot Rolledat great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1) Suitable for making various strong cutting tool abrasion resistance, impact resistance.

2) Used to produce all kinds of high hard and super hard saw blade, drill, tap, broach, gear hob and various kinds of milling cutter.

3) Used for advanced punching die, screw die, and the toughness and complicated shape of the punch, etc.

4) Is used for cold forging die and drawing mode, etc.

5) Recommended watchcase factory, screw factory and other cold stamping products industry use.

Product Advantages:

OKorder's Steel Square Bar Hot Rolled 5MM-28MM High Quality Hot Rolledare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard: GB,

-Grade: Q195 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

Measures of HR Square Bar (small measures):

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

7 | 0.385 | 22 | 3.80 |

8 | 0.502 | 24 | 4.52 |

9 | 0.636 | 25 | 4.91 |

10 | 0.785 | 26 | 5.30 |

11 | 0.950 | 28 | 6.15 |

12 | 1.13 | 30 | 7.06 |

13 | 1.33 | 32 | 8.04 |

14 | 1.54 | 34 | 9.07 |

15 | 1.77 | 36 | 10.17 |

16 | 2.01 | 38 | 11.24 |

17 | 2.27 | 40 | 12.56 |

18 | 2.54 | 42 | 13.85 |

19 | 2.82 | 45 | 15.90 |

20 | 3.14 | 48 | 18.09 |

21 | 3.46 | 50 | 19.63 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: (length of a side)2 * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

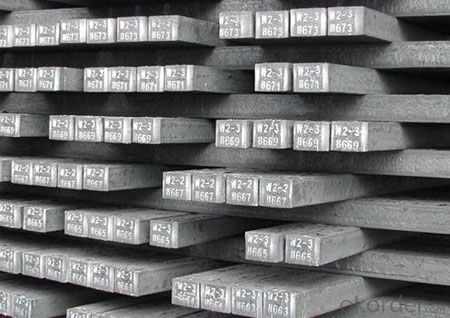

- Q: How are steel billets packaged for shipment?

- Steel billets are typically packaged for shipment in a way that ensures their protection and facilitates easy handling. The packaging process usually involves several steps to guarantee the safe transportation of the billets. Firstly, the steel billets are inspected to ensure they meet the required quality standards. Once approved, they are cleaned and dried to remove any dirt or moisture that could cause corrosion during shipment. Next, the billets are bundled together using steel strapping or wire to secure them in a compact form. This bundling not only prevents the billets from shifting or rolling during transportation but also facilitates easy handling and loading onto trucks or containers. To further protect the steel billets, they are often wrapped in a layer of plastic or paper. This additional layer acts as a barrier against moisture, dust, and other potential contaminants that could damage the billets during transit. Once the billets are bundled and wrapped, they are usually loaded onto pallets or placed in steel crates. This provides stability during transportation and allows forklifts or cranes to easily move and stack the packaged billets. Finally, the packaged steel billets are labeled with relevant information such as the product name, dimensions, weight, and destination. This labeling ensures accurate identification and helps in the efficient handling and delivery of the billets. Overall, steel billets are packaged for shipment in a way that prioritizes protection, ease of handling, and efficient transportation. These packaging measures ensure that the billets reach their destination in optimal condition, ready for further processing or use in various industries.

- Q: What are the different methods of steel billet surface painting?

- There are several different methods of steel billet surface painting that are commonly used in various industries. These methods include: 1. Spray painting: This is one of the most common methods, where a spray gun is used to apply a thin and even layer of paint onto the steel billet surface. It provides a smooth and consistent finish and allows for quick and efficient coverage. 2. Powder coating: In this method, a dry powder is applied to the steel billet surface using an electrostatic charge. The powder adheres to the surface and is then heated to form a durable and long-lasting coating. Powder coating offers excellent resistance to corrosion, chemicals, and abrasion. 3. Electroplating: This method involves immersing the steel billet into a solution containing a metal salt. A direct current is then applied, causing the metal ions in the solution to be deposited onto the surface of the billet. Electroplating provides a protective and decorative coating, enhancing the appearance and durability of the steel. 4. Hot-dip galvanizing: This method involves immersing the steel billet into a bath of molten zinc. The zinc forms a protective layer on the surface of the billet, providing excellent corrosion resistance. Hot-dip galvanizing is commonly used for outdoor applications where the steel is exposed to harsh environmental conditions. 5. Epoxy coating: Epoxy coatings are applied as a two-part system, where a resin and a hardener are mixed together and then applied to the steel billet surface. The epoxy cures to form a tough and chemical-resistant coating that provides protection against corrosion and abrasion. 6. Electrophoretic painting: This method involves immersing the steel billet into a tank containing a paint solution and applying an electric current. The paint particles in the solution migrate towards the billet surface due to the electric charge, resulting in a uniform and consistent coating. Each of these methods has its own advantages and disadvantages, and the choice of method depends on factors such as the desired finish, the environment in which the steel billet will be used, and the required level of protection.

- Q: How long do steel billets typically last?

- Steel billets typically last for a very long time. The lifespan of a steel billet depends on various factors such as the quality of the steel, the environment it is exposed to, and how it is used. Generally, high-quality steel billets that are properly stored and handled can last for several decades without any significant deterioration. However, if the billets are exposed to harsh environments or are not properly maintained, their lifespan may be shortened. It is important to note that steel billets can be recycled and reused, further extending their overall lifespan.

- Q: How can steel billets be recycled or reused?

- Steel billets can be recycled or reused in a number of ways. One common method is melting down the billets and using the molten steel to create new products. This process, known as remelting, allows for the steel to be reused in a variety of applications. Another way to recycle steel billets is by using them in the production of other steel products. For example, they can be used to make steel rods, pipes, or beams. By incorporating the billets into the manufacturing process, the steel industry can minimize waste and reduce the need for extracting new raw materials. Steel billets can also be repurposed in construction projects. They can be used as raw material for building structures, such as bridges, buildings, or highways. By using recycled steel billets, construction projects can reduce their environmental impact and contribute to a more sustainable future. Furthermore, steel billets can be transformed into smaller components through processes like rolling or forging. These components can then be used in various industries, including automotive, machinery, and infrastructure. By reusing steel billets in this way, we can reduce the need for producing new materials and conserve resources. Overall, recycling and reusing steel billets offer numerous benefits, including reducing waste, conserving resources, and promoting sustainability. With proper recycling and reuse practices, steel billets can have a second life in various industries, making them a valuable resource in the circular economy.

- Q: How are steel billets stored and transported?

- Steel billets are typically stored outdoors in large yards or warehouses, where they are organized in stacks or rows. To protect them from corrosion, billets are often covered with tarpaulins or anti-rust coatings. When it comes to transportation, steel billets are usually moved using heavy machinery like cranes or forklifts. They are loaded onto trucks, railcars, or ships, depending on the distance to be traveled. To ensure safety during transport, billets are secured with chains, straps, or other fastening methods to prevent shifting or falling.

- Q: What is the difference between steel and billet in the process?

- Square is a square steel hollow, with iron produced; but it is a square steel billet is generally solid, forging or casting molding.

- Q: What are the common uses of steel billets?

- Steel billets, serving as a precursor to different steel products, are semi-finished metal goods. They typically take on a solid, rectangular shape through continuous casting or hot rolling. Steel billets find wide application in various industries due to their strength and versatility. One of the primary uses of steel billets is in the production of long steel products like bars, rods, and wires. These billets act as the initial material for further processing, where they are reheated and shaped into the desired form. Long steel products are extensively employed in construction, infrastructure development, manufacturing, and transportation industries. Steel billets are also utilized in the manufacturing of seamless pipes and tubes. Through the process of piercing and elongation, the billets can be converted into seamless tubes, which are widely employed in oil and gas exploration, automotive manufacturing, and structural engineering. Moreover, steel billets play a vital role in producing forged steel components. Forging involves shaping the heated billet under pressure, resulting in durable and high-strength products. These forged components find wide application in industries such as aerospace, automotive, and power generation. Additionally, steel billets are used in the production of various other steel products, including beams, channels, and profiles for construction purposes, as well as machine parts and tools. In conclusion, steel billets serve as the starting material for the production of long steel products, seamless pipes, forged components, and other steel goods. Their malleability, strength, and versatility make steel billets an indispensable raw material in numerous industries.

- Q: What is the typical composition of a steel billet?

- The typical composition of a steel billet can vary depending on the specific grade and intended application. However, in general, a steel billet is primarily composed of iron, carbon, and other alloying elements. Iron is the main component of steel, typically making up around 98% of its composition. It provides the structural strength and durability of the material. Carbon is the second most important element, typically ranging from 0.02% to 2.1%. It plays a crucial role in determining the hardness and strength of the steel. Apart from iron and carbon, steel billets often contain various alloying elements to enhance specific properties. These alloying elements may include manganese, silicon, nickel, chromium, molybdenum, vanadium, and others. Each element contributes to different characteristics such as corrosion resistance, heat resistance, toughness, or machinability. Additionally, steel billets are often produced through processes like continuous casting or hot rolling, which can introduce small amounts of impurities. These impurities can include sulfur, phosphorus, and oxygen, which are typically kept to very low levels to maintain the desired quality of the steel. Overall, the typical composition of a steel billet encompasses a combination of iron, carbon, alloying elements, and minor impurities, which are carefully controlled to achieve the desired mechanical properties and performance for a wide range of applications, such as construction, automotive, aerospace, and manufacturing industries.

- Q: How are steel billets used in the manufacturing of marine components?

- Steel billets are an essential raw material used in the manufacturing of marine components due to their strength, durability, and versatility. Steel billets are essentially semi-finished steel products that are cast into a specific shape, usually a square or a rectangle, through a process called continuous casting. These billets then serve as the starting point for various marine components. One of the main ways steel billets are used in the manufacturing of marine components is through the process of hot rolling. Hot rolling involves heating the steel billet to high temperatures and then passing it between a series of rollers to shape it into the desired form. This can include forming the billet into rods, bars, beams, or other structural shapes that are commonly used in marine applications. Steel billets are also used in the manufacturing of marine components through the process of forging. Forging involves heating the billet to high temperatures and then applying pressure to shape it into the desired form. This process is commonly used to manufacture marine components such as propeller shafts, crankshafts, and other high-strength parts that require precise shaping and superior mechanical properties. Additionally, steel billets can be used in the manufacturing of marine components through the process of machining. Machining involves removing material from the billet using various cutting tools to create complex shapes and features. This process is commonly used to manufacture marine components such as valves, fittings, and other precision parts that require tight tolerances and intricate designs. In summary, steel billets play a crucial role in the manufacturing of marine components. Their strength, durability, and versatility make them an ideal raw material for producing various marine parts through processes such as hot rolling, forging, and machining. By using steel billets, manufacturers can ensure that the marine components they produce are capable of withstanding the harsh conditions and demanding requirements of the marine environment.

- Q: Are steel billets subject to any regulations or certifications?

- Yes, steel billets are subject to various regulations and certifications. These regulations and certifications ensure that the steel billets meet specific quality standards, safety requirements, and environmental regulations. Some common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and certifications from industry-specific organizations like the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). Additionally, steel billets may need to comply with specific regulations in the country or region where they are produced or used, such as building codes or product safety regulations.

Send your message to us

Steel Square Bar Hot Rolled 5MM-28MM High Quality Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords