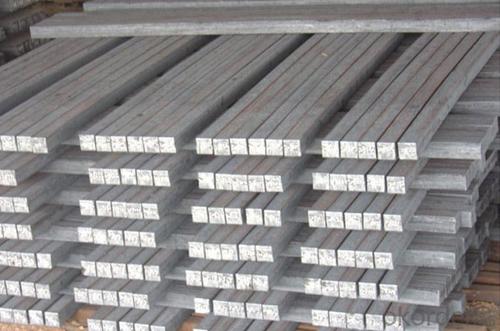

Steel Square Billet Bar For Rebar Production

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Range of thickness: 150-240 - mm +/- 5 mm width range: 880-1530 - mm +/- 20 mm

Length: 3700-10000 - mm +/- 500 - mm

Cross-sectional size: 64 * 64; 82 * 82; 98 * 98; 124 * 124; 120 * 150; 152 * 164; 152 * 170 mm

Length: 9000 mm

Section of tolerance: billet: 1.0 +/- 2.0-1.0 +/- 1.0 mm slab: width: +/- 2.0 mm thickness: +/- 3.0 mm

The length tolerance: +/- 200 mm

Section diagonal tolerance: 3.5-8.0 MM

Billet section size protrusions requirements: < 1242 mm, do not allow; > = 1242 mm, < = 2 mm 1242 mm, < = 3 mm

Beheading (shear) extension deformation: < 1242 mm billet: no control; The slab: < = 15 mm

Surface tilt: no more than billet section 0.1

Bending: every 1 m length is not more than 10 mm.

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: (length of a side)2 * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

Usage/Applications

-The Square Bar is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks: We make tag marks and color marks. The tag marks with white background and red company logo will be tied up to each bundle of the products. The information is usually including basic information of products and company and other information requested by customers. As for color marks, we will paint both ends of bundles to make sure that it will be more convenient for customers to distinguish them from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products are usually transported to the nearest port from the production place.

- Q: What are the different types of steel billet handling equipment?

- Some different types of steel billet handling equipment include overhead cranes, forklifts, conveyors, and magnetic lifting devices.

- Q: What are the specifications for steel billets used in the defense industry?

- The specifications for steel billets used in the defense industry typically include requirements for specific chemical composition, mechanical properties, dimensions, and surface quality. These specifications ensure that the steel billets possess the necessary strength, durability, and resistance to withstand rigorous applications in defense equipment and structures.

- Q: Can steel billets be used in the production of medical equipment?

- Certainly, medical equipment can utilize steel billets. Renowned for its robustness, longevity, and resistance to deterioration, steel proves to be an optimal substance for fabricating diverse medical apparatus. Steel billets, the preliminary intermediate product in steel production, can undergo additional processing and molding to form precise components or parts indispensable for medical equipment. Such components encompass surgical instruments, implants, orthopedic devices, needles, and other medical implements. The mechanical attributes of steel and its capacity to endure sterilization procedures render it a fitting preference for manufacturing dependable and secure medical equipment.

- Q: Can steel billets be used in the production of kitchenware?

- Kitchenware can indeed be made using steel billets. Steel billets, which are essentially unfinished steel products that have been cast into a rectangular shape, can undergo further processing through methods such as forging, rolling, or extrusion. These processes allow for the creation of a wide range of kitchenware items, including pots, pans, utensils, and cutlery. The use of steel in kitchenware production is popular due to its exceptional strength, durability, and resistance to heat. It is also well-known for its ability to resist corrosion, making it safe for contact with food and liquids. Furthermore, steel is easy to clean and maintain, making it a hygienic choice for kitchenware. The typical manufacturing process involves heating and shaping the steel billets into the desired form, followed by finishing processes like polishing or coating to improve both the aesthetics and functionality of the kitchenware. With the versatility to produce kitchenware in various shapes, sizes, and designs, steel billets provide a flexible solution for creating high-quality and long-lasting kitchenware items.

- Q: What is the typical density of a steel billet?

- The density of a steel billet is contingent upon the particular type of steel employed. Nonetheless, in broad terms, the range of density for a steel billet falls between 7.75 and 8.05 grams per cubic centimeter (g/cm³). This density may exhibit slight fluctuations due to the steel's composition and quality. It is crucial to acknowledge that the presence of any impurities or contaminants in the material may additionally impact the density of a steel billet.

- Q: Can steel billets be customized according to specific requirements?

- Yes, steel billets can be customized according to specific requirements. Steel billets are semi-finished products that are typically used for further processing to produce various steel products, such as bars, rods, and wire. The customization of steel billets involves adjusting their dimensions, chemical composition, and mechanical properties to meet the specific needs of different applications. Steel billets can be customized in terms of their size and shape. Depending on the requirements, the length, width, and thickness of the billets can be modified to ensure optimal efficiency during subsequent processing. Additionally, the shape of the billets can be customized to match the desired end product, such as square, round, or rectangular. Furthermore, the chemical composition of steel billets can be customized to achieve specific properties. By adjusting the percentage of various elements, such as carbon, manganese, and alloying elements like chromium or nickel, the steel can be tailored to exhibit certain characteristics, such as increased strength, improved corrosion resistance, or enhanced weldability. Finally, the mechanical properties of steel billets can be customized through heat treatment processes. Heat treatment techniques like quenching and tempering can be applied to control the hardness, toughness, and overall strength of the steel, making it suitable for specific applications. Overall, steel billets can be customized in terms of size, shape, chemical composition, and mechanical properties to meet specific requirements, ensuring that they can be effectively used in various industries and applications.

- Q: What is the role of steel billets in the construction of dams and reservoirs?

- The role of steel billets in dam and reservoir construction cannot be overstated. These semi-finished steel products are vital for manufacturing various components and structures necessary for the construction process. A primary application of steel billets in dam and reservoir construction is their use in producing reinforced concrete. Reinforced concrete combines the strength and durability of steel with the versatility and moldability of concrete. Steel billets are utilized to create steel reinforcement bars, commonly called rebars, which are embedded within the concrete to improve its tensile strength and prevent cracking when subjected to heavy loads. These rebars provide the necessary structural support for the dam or reservoir, ensuring its stability and long life. Furthermore, steel billets are essential for fabricating gates, penstocks, and other mechanical components required for dams and reservoirs. These components play a crucial role in regulating water flow, controlling water levels, and managing the release of water from the reservoir. Steel billets are forged, rolled, or machined to manufacture these specialized components, guaranteeing their strength, reliability, and resistance to corrosion. Moreover, steel billets are indispensable in constructing spillways, which are designed to safely discharge excess water from reservoirs during periods of heavy rainfall or floods. Spillway gates, channels, and other structures are often made from steel billets because they need to withstand high water pressure and turbulent flow conditions. To summarize, steel billets are vital in dam and reservoir construction. They are instrumental in producing reinforced concrete, thereby providing structural support and enhancing the overall strength of the structure. Steel billets are also used in the production of gates, penstocks, spillways, and other mechanical components, ensuring the efficient operation and long-term durability of these crucial water management infrastructures.

- Q: What are the different methods of steel billet surface finishing?

- There are several methods of steel billet surface finishing that are commonly used in the industry. These methods include: 1. Shot blasting: Shot blasting is a common method used to clean and prepare steel billets for further processing. It involves propelling abrasive particles at high speeds onto the surface of the billets. This process removes any rust, scale, or impurities from the surface, resulting in a clean and smooth finish. 2. Grinding: Grinding is another method used to achieve a smooth and even surface finish on steel billets. It involves the use of abrasive wheels or belts to remove material from the surface of the billets. Grinding can be done manually or using automated machinery, depending on the requirements and size of the billets. 3. Polishing: Polishing is a process that is typically used to achieve a high-gloss, reflective finish on steel billets. It involves the use of polishing compounds and buffing wheels to smooth out the surface and enhance its appearance. Polishing is often used for decorative purposes or when a high-quality finish is required. 4. Acid pickling: Acid pickling is a method used to remove any oxide scale or rust from the surface of steel billets. It involves immersing the billets in an acid solution, such as hydrochloric acid, to dissolve the impurities. Acid pickling is an effective way to achieve a clean and uniform surface finish on steel billets. 5. Passivation: Passivation is a process that is often used to improve the corrosion resistance of steel billets. It involves the immersion of the billets in a passivating solution, typically a mixture of nitric acid and water, to remove any surface contaminants and promote the formation of a protective oxide layer. Passivation can help to prevent the formation of rust and extend the lifespan of the steel billets. Overall, the choice of method for steel billet surface finishing depends on the desired finish, the size and shape of the billets, and the specific requirements of the application. Each method has its own advantages and considerations, and it is important to carefully select the appropriate method to achieve the desired surface finish.

- Q: What are the common challenges in steel billet production?

- Some common challenges in steel billet production include ensuring consistent quality and composition, maintaining precise dimensions and tolerances, managing temperature control during the casting process, preventing defects and surface imperfections, and optimizing production efficiency and yield. Additionally, factors such as raw material quality, equipment maintenance, and skilled workforce are also critical in overcoming these challenges.

- Q: What are the different types of surface finish inspection methods for steel billets?

- Steel billets can undergo various surface finish inspection methods to determine their quality and suitability for further processing or use. Some commonly used methods for inspecting the surface finish of steel billets include the following: 1. Visual inspection: This method involves visually examining the surface of the billet for any irregularities, such as cracks, pits, scratches, or other imperfections. Although it is a quick and cost-effective method, it may not be able to detect subtle defects. 2. Magnetic particle inspection: This method entails magnetizing the billet's surface and applying fine iron particles to it. Any surface cracks or defects will cause a leakage of the magnetic field, attracting the iron particles and making them visible under appropriate lighting conditions. 3. Dye penetrant inspection: This method involves applying a liquid dye to the billet's surface. The dye seeps into any surface cracks or defects, and after a certain period, excess dye is removed. A developer is then applied, which draws out the dye from the cracks and defects, making them visible. 4. Ultrasonic testing: This method utilizes high-frequency sound waves transmitted through the steel billet. When the waves encounter any surface irregularities, such as cracks or voids, they are reflected back. By analyzing the time taken for the waves to return, the size and depth of the defects can be determined. 5. Eddy current testing: This non-destructive testing method utilizes electromagnetic induction to detect surface defects. An alternating current is passed through a coil, creating a magnetic field. When the coil is near the billet's surface, any defects disrupt the magnetic field, causing a change in the electrical impedance. This change is measured and analyzed to identify surface defects. Each of these inspection methods has its advantages and limitations. The choice of method depends on specific requirements, the size and shape of the billet, and the desired level of accuracy. Manufacturers can ensure the quality and reliability of the steel billets by employing these surface finish inspection methods before further processing or using them in various applications.

Send your message to us

Steel Square Billet Bar For Rebar Production

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords