Box Girder Steel Formwork System

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

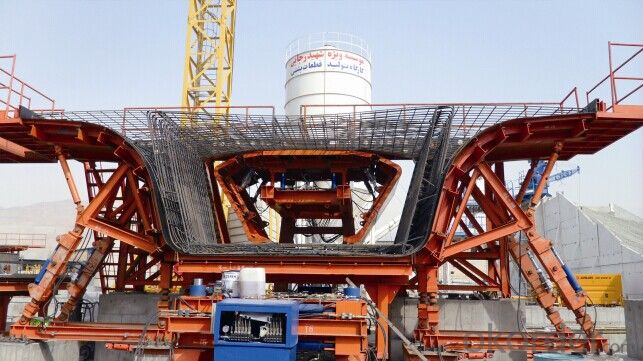

1. Structure of Box Girder Steel Formwork System

A vertical support system widely used in construction of slab or shoring. The prop has simple structure; it is easy to operation and has perfect adjustment to each individual job site requirement, all these features decide that the props play an irreplaceable role in slab or shoring construction.A vertical support system widely used in construction of slab or shoring. The prop has simple structure; it is easy to operation and has perfect adjustment to each individual job site requirement, all these features decide that the props play an irreplaceable role in slab or shoring construction.

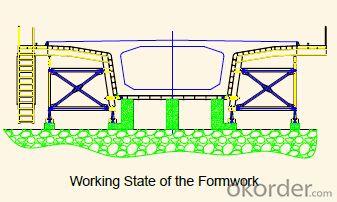

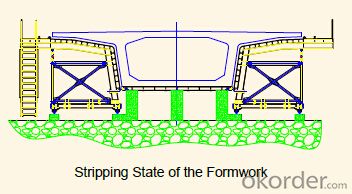

External formwork of 32/24 meters post-tensioning concrete prefabricated box girder is divided into sliding mode and rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency of formwork closure.The side formwork unit is mainly 6 meters, the design of the structure is compact and reasonable with beautiful and smooth appearance.

2. Main Features of Box Girder Steel Formwork System

A) All the edges of external formwork panels for the box girder have been milled, which ensure the assembly precision to avoid the leakage of the concrete.

B) The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment.

C) The bulkhead is designed to envelop the side-form,which can be wholly assembled, making the removal, installation and adjustment much easier.

3. Box Girder Steel Formwork System Images

4. Box Girder Steel Formwork System Specification

5. FAQ of Operating Platform

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Box Girder Steel Formwork System, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Box Girder Steel Formwork System, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How to put the beam formwork in concrete structure

- By way of hanging on the board, you do not want to put a line for you!

- Q: What is the foundation beam template

- I was in the study of this problem, it should be the construction is not based on beam design has been explained, but the quota is a little different, the beam bottom cushion or other basis should be the beam, it should be suspended under the general frame or beam. The difference is that the two side support and the three side support. Usually the explanation is still looking for evidence.

- Q: What is the meaning of the steel beam overhead on the top of the beam formwork

- Because the carpenter is generally the template will be good, so that there is no reinforcement steel reinforcement

- Q: The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- Note: when the right angle fastener tightening torque of 40--65N.m, test shows that the single fastener will slide in the 12kN under the load, the sliding bearing capacity of desirable 8.0kN; double fastener will slide in the 20kN under the load, the sliding bearing capacity to be 12.0kN.Note: the above values are experimental values! Take a look at your calculation results and this value to meet the double anti sliding bearing capacity can be!

- Q: The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- Figure is too small, the eyes are looking at flowers.1, floor 12.24*7.44 is the bottom of the whole plate (including the bottom of the beam), and then subtract the column area. Board only need to calculate the bottom and side die on the line, do not use *2.

- Q: The section size of the beam is 200 x 400 the size of the board is 4500 x 4000 plate thickness of the formula for 120 - a rookie

- Building template:Building template is a temporary support structure is made according to the design requirements, the concrete structure components, according to the position and size of the provisions of forming, maintaining its correct position, external loads and under construction template gravity and acting on the. The purpose of template engineering is to ensure the quality of concrete engineering and construction safety, speed up the construction progress and reduce the cost of the project.This paper introduces the construction formwork structure of cast-in-place concrete structure construction, which is mainly composed of three parts: the panel, the supporting structure and the connecting parts. The panel is in direct contact with the bearing plates of concrete; supporting structure is a temporary structure supporting panel, concrete and construction load, ensure the construction template are firmly combined, do not deform and damage; the connecting piece is connected to the panel and the supporting parts of the whole structure.Building formwork is the concrete pouring forming shell and support, according to the nature of the material can be divided into building template, building wood plywood, covered with plastic board, multilayer board, double-sided adhesive, double-sided coated building template. According to the construction process, the construction formwork can be divided into the cast in place concrete formwork, the pre assembled template, the large formwork, the jump formwork and so on.

- Q: How to support 6m arc beam template how to set up?

- If you use a supporting beam of radian template, the bottom surface made of a whole block template (template block with good reinforcement, pouring backwater) after dismantling the entire arc shape template on the line; if the second half of the same radian can do a whole half arc template do the bottom die.

- Q: For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- Column according to the circumference of the column by column height, Liang Anliang on both sides of the beam after the end of the beam length, according to the net floor area of the room (excluding wall width or Liang Kuan) calculation.

- Q: What is the demolition order of the construction template

- 3 the demolition of multilayer floor pillar shall be carried out according to the following requirements: when the upper floor slab is pouring concrete, the next floor slabThe pillar shall not be removed, then the next floor of a live, can only be removed part of the span is 4M or above 4M Xiajun should retain the brace beam, pillar spacing shall not be greater than 3M.

- Q: The main floor beam template installation should pay attention to what?

- See the technical disclosure records, the main operating process1) according to the axis of the 500mm line and the horizontal elevation control line on the concrete cylinder.

Send your message to us

Box Girder Steel Formwork System

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords