Ball Valve For Heating SupplyDN 65 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

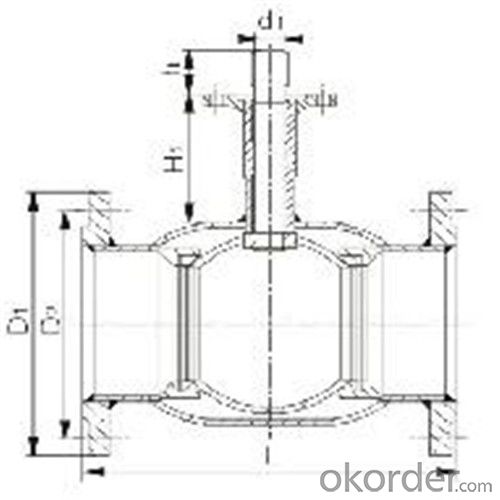

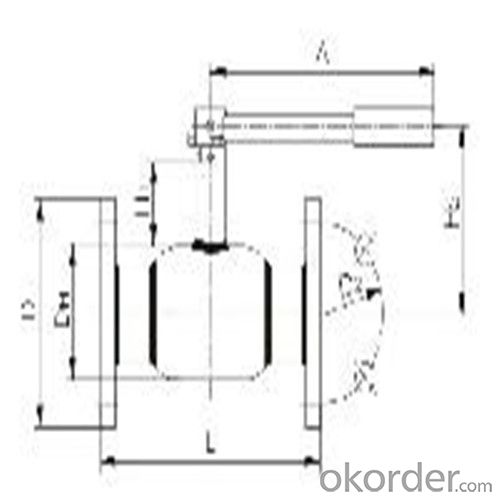

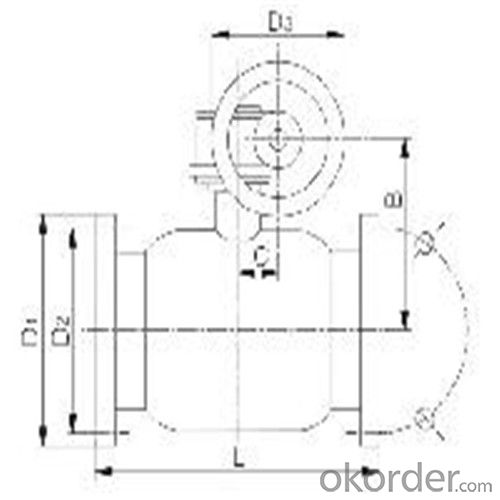

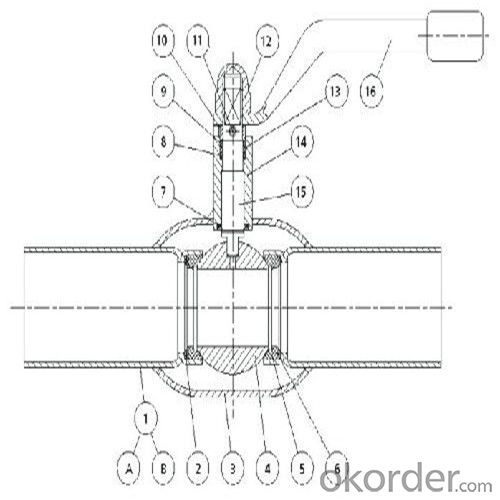

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Is it possible for car manufacturers to make 32 / 64 / 128 / 512 Valve Car Engine just like in a PC CPU? The highest valve I saw so far is 16-valve engine. Just asking :-)

- There would be no point to having such high valve count. The point of more valves is to cover the cylinder head combustion chamber with flow spaces. Topologically this is pretty well done with 4 or 5 valves. It is very expensive to add the 5th valve so most manufactureres are happy with 4 valves/cylinder. The largest 4valve / cylinder engine in mass production would be the GM/Caddilac Northstar V-8 IIRC. More analogous to your CPU question would be the use of multiple cylinders, not valves. As far as I know, the largest mass produced engines for auto use have been V-12's as found on high end BMW's and Jaguar's. At a given displacement, engines become more powerful and efficient with more cylinders. Go figure, just the opposite of PC CPU's! I'm sure there are large stationary or ship engines that are made with 32 cylinders, maybe more. The largest I've seen though had 24 and was used to generate electricity for a corporate campus. Astrobuf

- Q: Im replacing the valve stem seals and i dont know how to remove the springs and with the valve compressor wont fit in the engine

- Do NOT do what banit said, if you did his technique once you remove the keepers the valve would drop to the bottom of the cylinder and require a tear down. You must get the piston be at top dead center on the cylinder you intend on removing the valve springs from and you cannot do any other valves besides the ones on the cylinder you brought to top dead center. You can take the rocker arm off the top and take the push rod out then when at top dead center using a spring compressor you can take the keepers out, or if you do not have a spring compressor (proceed at your own risk) you can get an oversized socket and a dead blow hammer and place the socket over the top of the valve spring with the octagonal side towards the spring and give it a decent hit, but be aware the keepers will pop out and you may lose them if you are not careful.

- Q: Ball valves are much more reliable. Also, if you have the gate valve for the main shutoff, is it against code to put a ball valve right after it, so you have a working shutoff when the gate valve fails?

- no as long as the gate valve is there. gate valves are pressure rated and seal better and are made from hardened steel so it will usualy seal when others have a seat [made from brass] that can wear out and leak even ball valves have a ceramic or plastic seal and are made from brass or soft steel

- Q: when riding my motorcycle valves start knocking i took to a mechanic and they did not resolve problem. i have baby ed my motorcycle. dint know what to do at this point and time.

- A lot of times you will not hear a valve problem, They tend to tighten up with age not loosen. On sign of a valve out of adjustment is if bike is hard to start when cold. knocking could be loose timing chain, timing chain tension-er needs attention.,Could also be worn drive chain. It will make a popping sound when its stretched out. Some front brake calipers will make a knocking sound, its the pads rattling around between calipers and rotors.

- Q: compare the structure of the tricuspid valve with that of the pulmonary valve??please help me

- Structure Of Pulmonary Valve

- Q: does anyone know how much work it would take for a 1998 Mazda 626 (2.0L MFI DOHC) to change a bad intake valve?what work would be necessary and what kind of price are we talkin?

- What diagnosis gave you the fact that you need a cvalve changed...dis you not replace the timing belt and it bent the valves(major head repair) or did you do a compression check to determine you have bent valve (intake valves don't burn) (lesser repair)

- Q: I have 06 Suzuki gsx-r 750 and i was wondering what are the signs or how do i know that my valves need to be adjusted?

- Actually, your valves will not clatter, they will get very quiet. Valve clearances ordinarily tend to tighten up over time. A tappy valve is a happy valve. Measure the clearances with a feeler gauge to tell if they need adjustment. Some early warning signs of tight valve clearances include an unstable idle, stalling on the overrun, and stumbling off idle. You should also keep a record of your clearances before adjustment, shim sizes as found, clearance after adjustment, shim sizes after adjustment, and mileage. That information will help you anticipate adjustments, give you an idea of what shim sizes to have on hand, and give you an indication of any unusual wear patterns. Keep this information in mind when chasing carb and ignition problems, too. Driveability issues attributed to carburetion are often caused by tight valve clearances instead. If it has been a while since your last valve adjustment, set them first, before chasing carb issues.

- Q: just picked up my test results from cardiologist and I see it says: Assessment: 1+ tricuspid valve insufficiency and 1+ pulmonic valve insufficiency Aim 19 years old this test is a year old. (Never went back to the doc to get them until now) the reason I went back is because I feel a slight discomfort in my chest from time to time. Is not pain just discomfort that I get from walking moderate distance or lifting 20+ LB things. Please help

- I easily have / had a nicely documented by using protection force Dr's (i become a protection force Brat) murmurer, I went to MEPs in 1979. 2 diff Dr's listened to my heart and that i handed the Phys. The Air stress realized about 6 months in via me getting ill and going into the well being midsection(when I run a extreme temp it shows up extra). i become despatched to a civilian heart specialist who after operating many try recommended the AF that i does no longer have any issues. Vet-USAF ad: My finished existence the Dr's would tell me i'd not in any respect get contained in the protection force. reliable success

- Q: Just bought car used. It is an 88 Toyota Corolla Fx. It is leaking and loosing a lot of oil. The EGR valve is spraying pretty badly. All hoses are fine. Seems to be in the seal. Is this the possible fix I need to solve these problems? Cleaned and inspected engine for other leaks and found none. Please help. Very poor and highly motivated to fix this car up.

- Hello, The EGR valve will not spray oil, It is an exhaust gas recirculation valve that does not have oil get to it!! Please add more info so we can better answer your question . Thanks for additional info. But I don't think you know what the EGR valve is. Engine oil should not be spraying from the EGR valve ! Maybe you are trying to describe another part? Also, You need to fix the wheel cylinder or caliper before you can bleed the brakes. Maybe you need a mechanic to assist you. Good luck !

- Q: 1995 Yukon need valve lash adj- how and hat tools?

- remove valve covers, watch front left two lifters and turn engine, by bolt that holds harmonic dampener to front of crankshaft, so mark on dampener lines up with mark on front cover. If rocker arms do not move as marks line up engine should be on top dead center number 1 cylinder. Now you can adjust exhaust valves 1, 3, 4, 8 and intake valves 1, 2, 5, 7 [ odd numbers are on the left bank from the front 1,3,5,7 even on the right bank from the front 2,4,6,8]. Adjust by turning nut in rocker arm out until movement is felt than tighten until all movement is gone and tighten one turn more. After done with the first eight valves turn engine over one full turn till marks line up again. Then adjust exhaust valves 2,5,6,7 and intake valves 3,4,6,8 the same way.

Send your message to us

Ball Valve For Heating SupplyDN 65 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords